3. ENGINE

3-

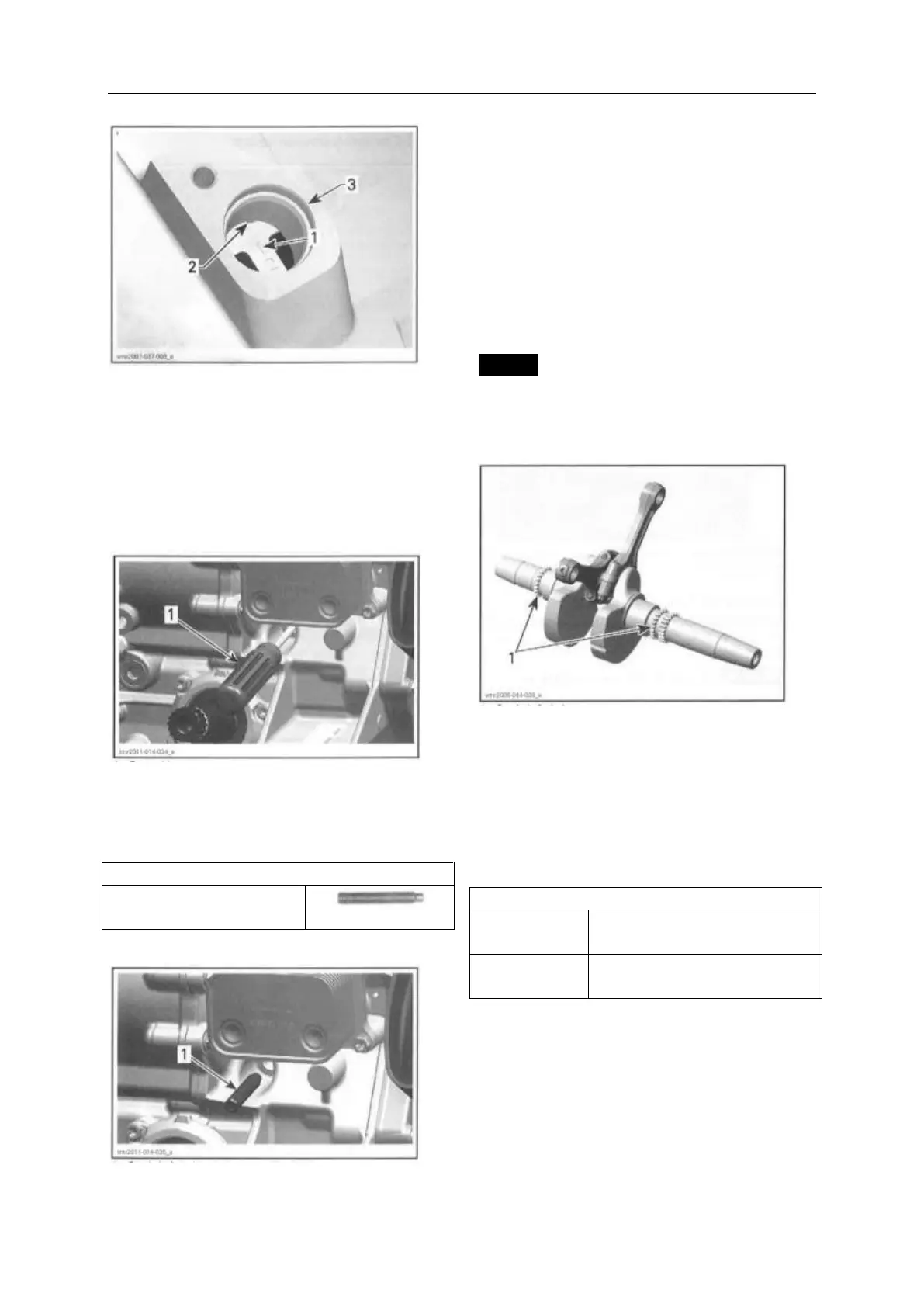

1. Mark“2”on magneto flywheel

2. Notch on magneto cover

3. Crankshaft position sensor location

Use a screwdriver to check if the groove in the

crankshaft is aligned with the hole.

1. Screw driver

Lock crankshaft

1. Crankshaft locking bolt

Gradually insert the tool in the crankshaft groove.

Make sure that the tool tip enters the groove and

does not jam on the crankshaft balancer surface.

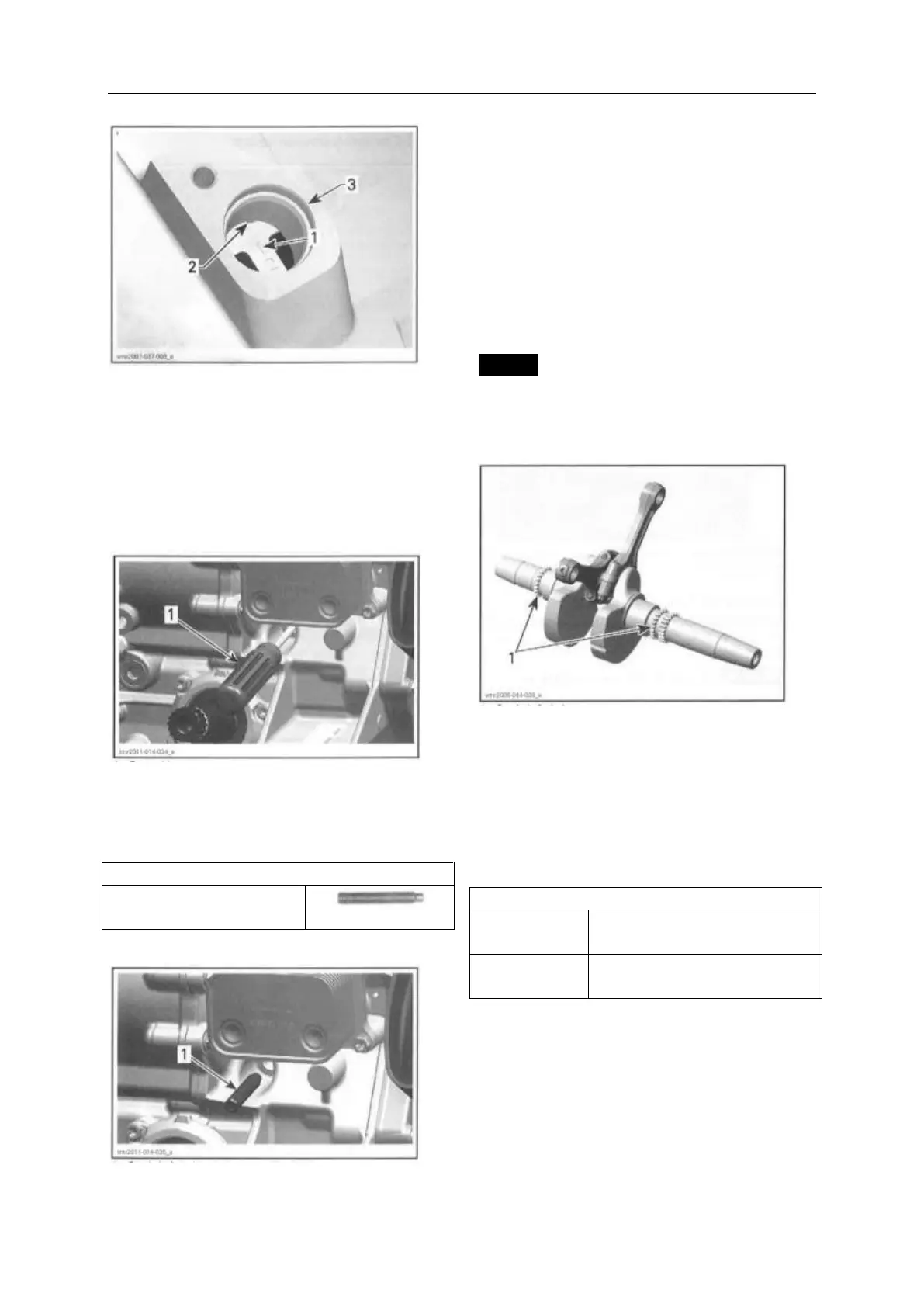

Crankshaft Removal

Refer to CRANKCASE

Crankshaft Inspection

NOTE: Check each bearing journal of crankshaft

for scoring, scuffing, cracks or other signs of wear.

NOTE: Replace crankshaft if the gears are worn or

otherwise damaged.

NOTICE Components out of specifications always

have to be replaced .If this is not observed, severe

damage may be caused to the engine.

1. Crankshaft timing gears

Crankshaft Axial Play

NOTE: Axial play needs to be measured before

splitting the crankcase.

Measure play on PT0 end, using a dial indicator.

0.200 mm to 0.500 mm

(.008in to.02in)

If play is out of specification, replace crankcase

and/or crankshaft.

Connecting Rod Big End Axial Play

Using a feeler gauge, measure distance between

butting face of connecting rods and crankshaft

counterweight . If the distance exceeds specified

tolerance, replace the crankshaft.

Loading...

Loading...