3. ENGINE

3-

Inspection

Driven pulley should be inspected annually for

wear or damages.

Check sliding and fixed sheave for cracks and

sliding contact surface for excessive wear.

Replace sliding sheave if necessary.

Check sliding sheave bushings for cracks,

scratch and for free movement when assembled

to sliding sheave.

Check ball bearing for free play and smooth

operation. Replace if necessary.

Installation

For installation, reverse the removal procedure. Pay attention to the following details.

Chamfer on inside diameter of the spacer must face engine side.

Clean pulley faces and shaft with dry cloth.

Driven pulley is a spring loaded system.

Always place washer at the time of driven pulley installation.

When the driven pulley is blocked, torque screw to 60N.m.

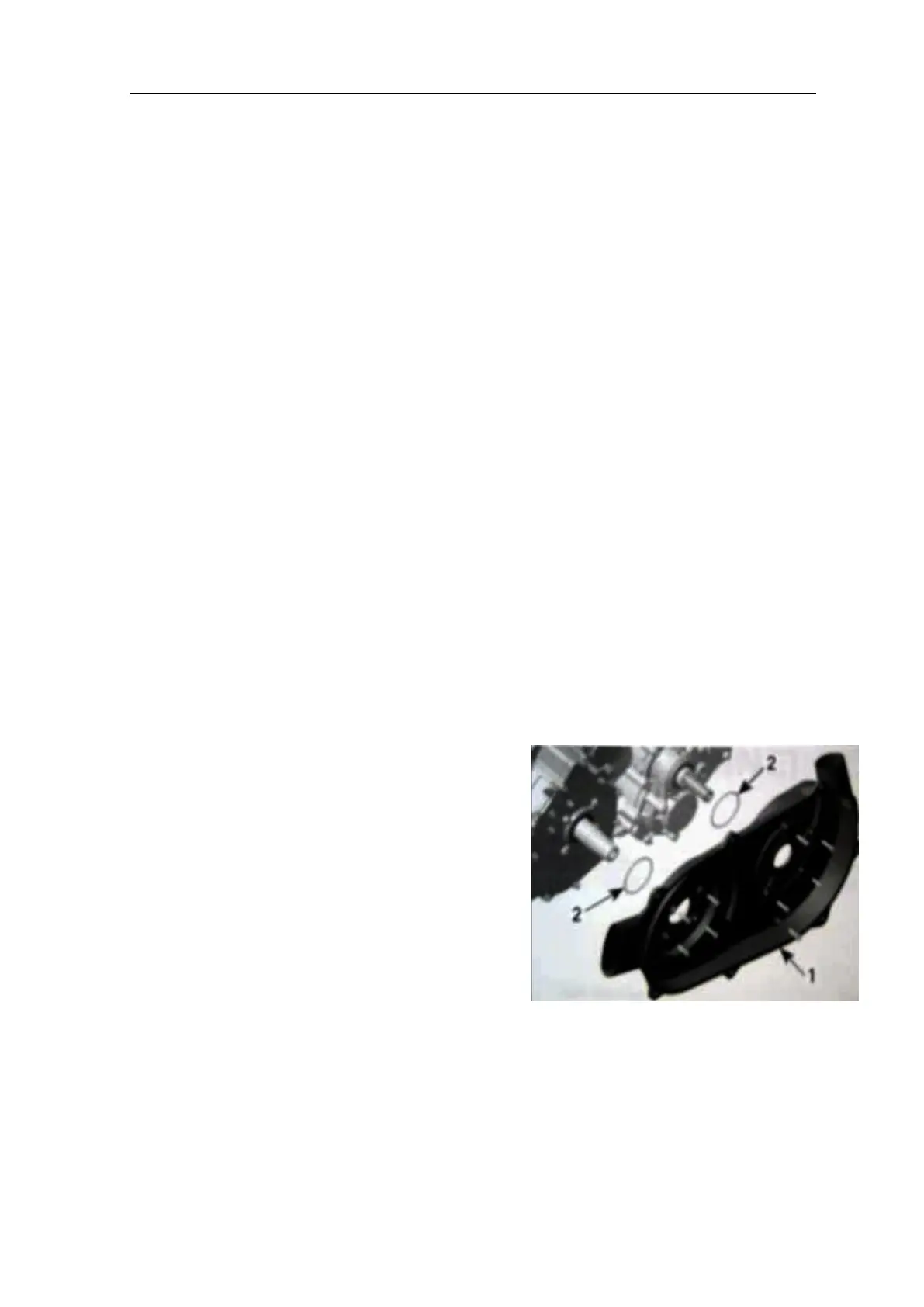

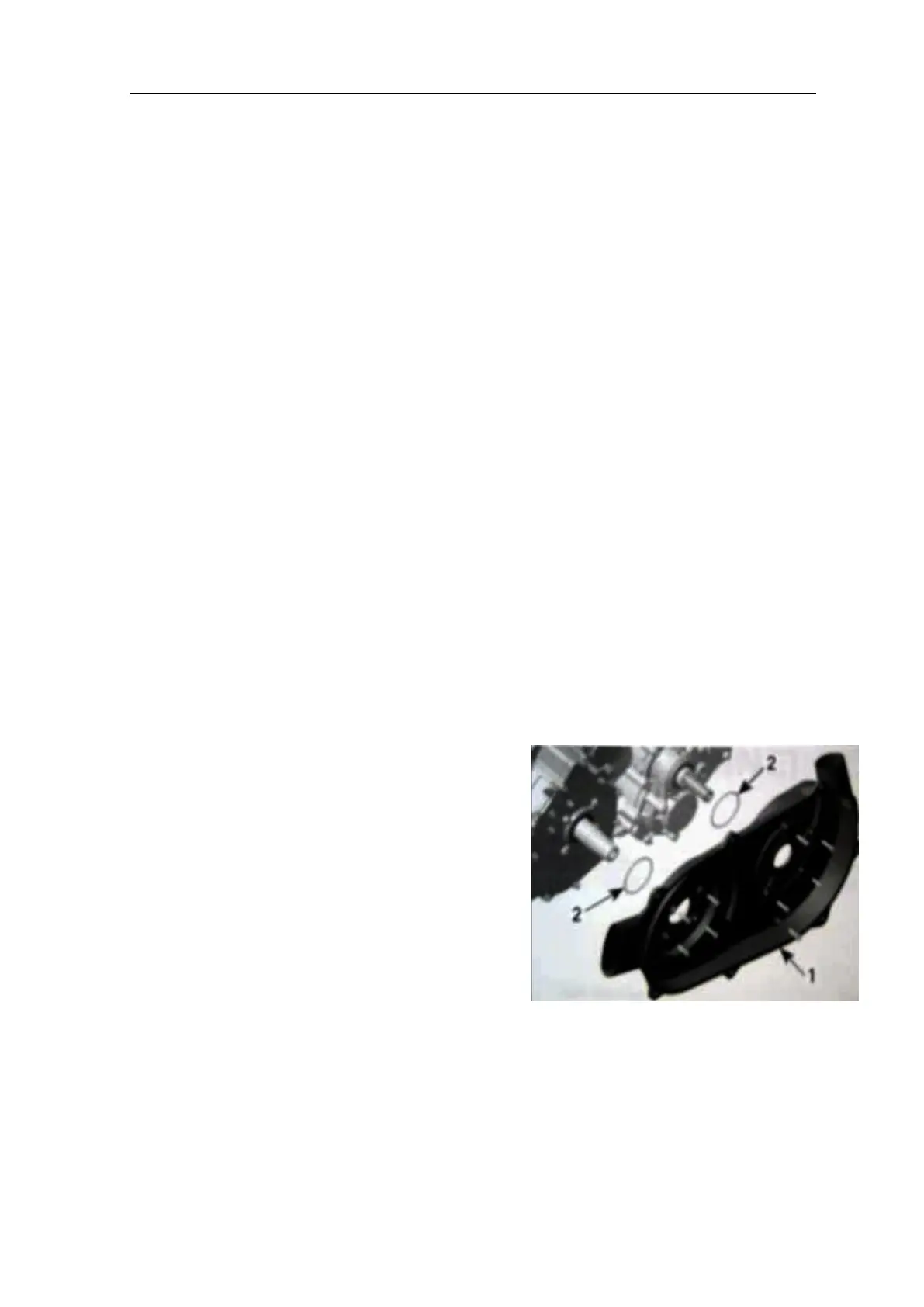

CVT AIR GUIDE

Removal

Remove:

Variator cover

Drive belt

Drive pulley

Driven pulley

Unscrew the clamps retaining the CVT air

hoses

Remove CVT air guide.

Inspection

Clean CVT air guide from contamination.

Check O-rings if brittle, hard or damaged.

Replace if necessary.

1. CVT air guide

2. O-rings

Installation

For installation, reverse the removal procedure.

Loading...

Loading...