2.PERIODIC MAINTENANCE

2-

Valve clearance of cylinder 2

Use a 14 mm Allen key to turn crankshaft

until piston 2, rear is at TDC ignition.

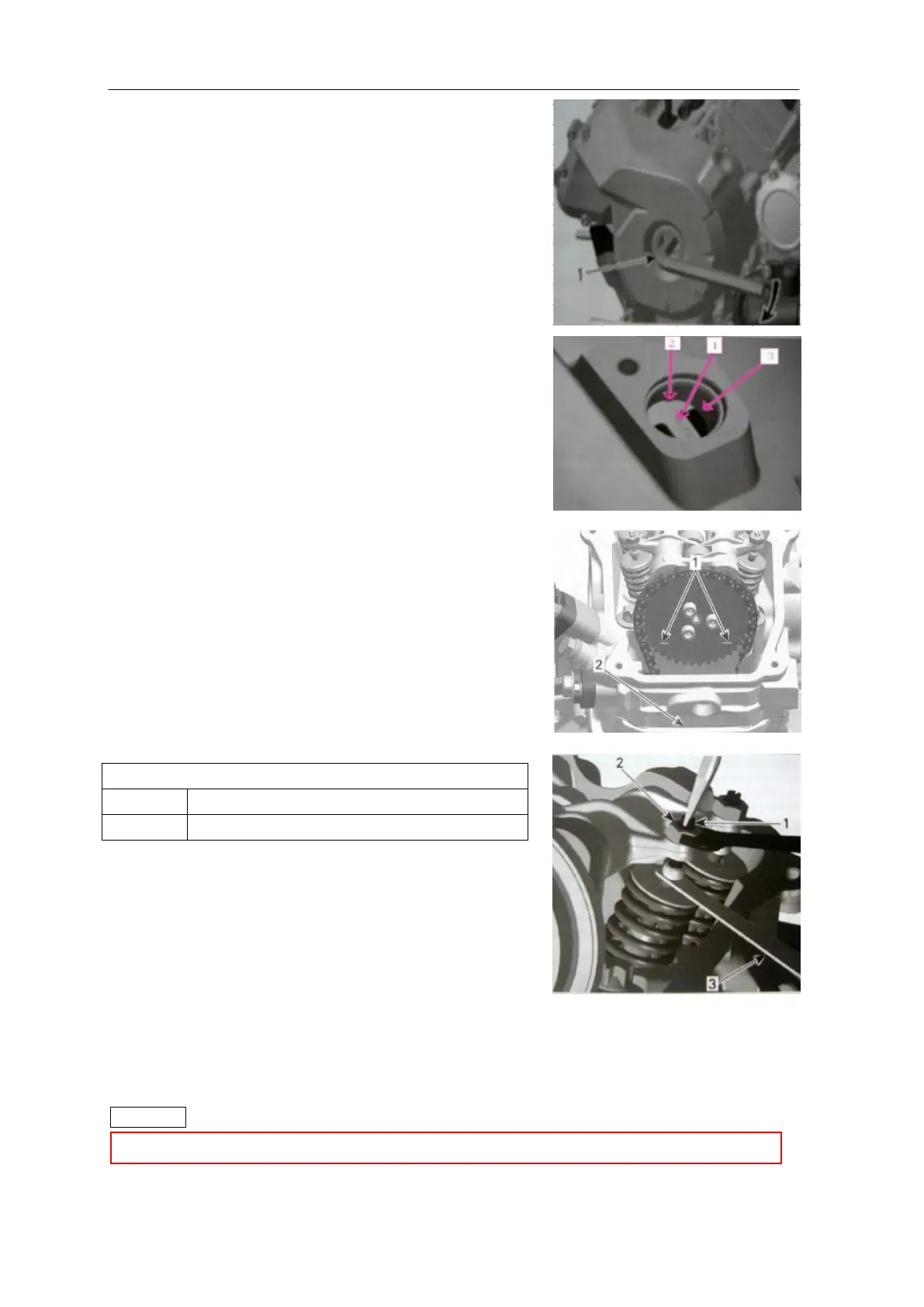

When rear piston is at TDC ignition, marks on

magneto flywheel “2” and on the magneto

cover are aligned.

1. Mark “2” on magneto flywheel

2. Notch on magneto cover

3. Crankshaft position sensor location

At TDC ignition, the printed marks on the

camshaft timing gear have to be parallel to

cylinder head base. If not, use Allen key to turn

crankshaft 360°

1. Printed marks on camshaft timing gear

2. Cylinder head base

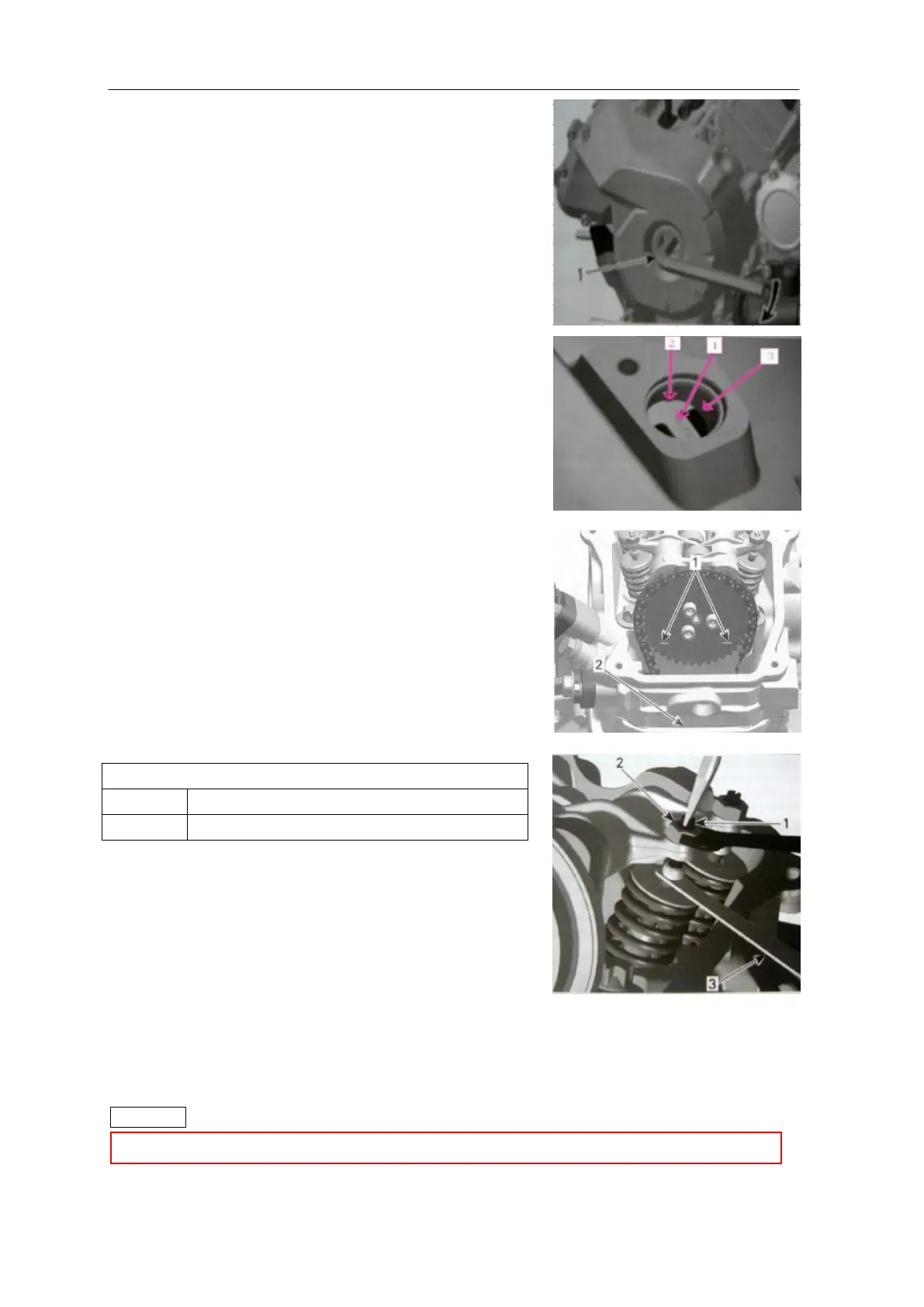

Insert the feeler gauge between the valve

stem end and adjusting screw on the

rocker arm to check the clearance.

If the valve clearance is out of specification,

adjust valves as follows.

0.06 to 0.10mm(0.00236 to 0.00394 inches)

0.11 to 0.15mm(0.00433 to 0.00591 inches)

Use mean valve of exhaust/intake to ensure a

proper valve adjustment.

Hold the adjustment screw at the proper

position and torque the locking nut.

Repeat the procedure for each valve.

1. Adjustment screw

2. Adjustment nut

3. Feeler gauge

CAUTION

Valve clearance adjustment locknut:12N.m(8.856Lbf.ft)

Securely tighten the locknut after completing adjustment.

Loading...

Loading...