2.PERIODIC MAINTENANCE

2-

ENGINE COMPRESSION PRESSURE

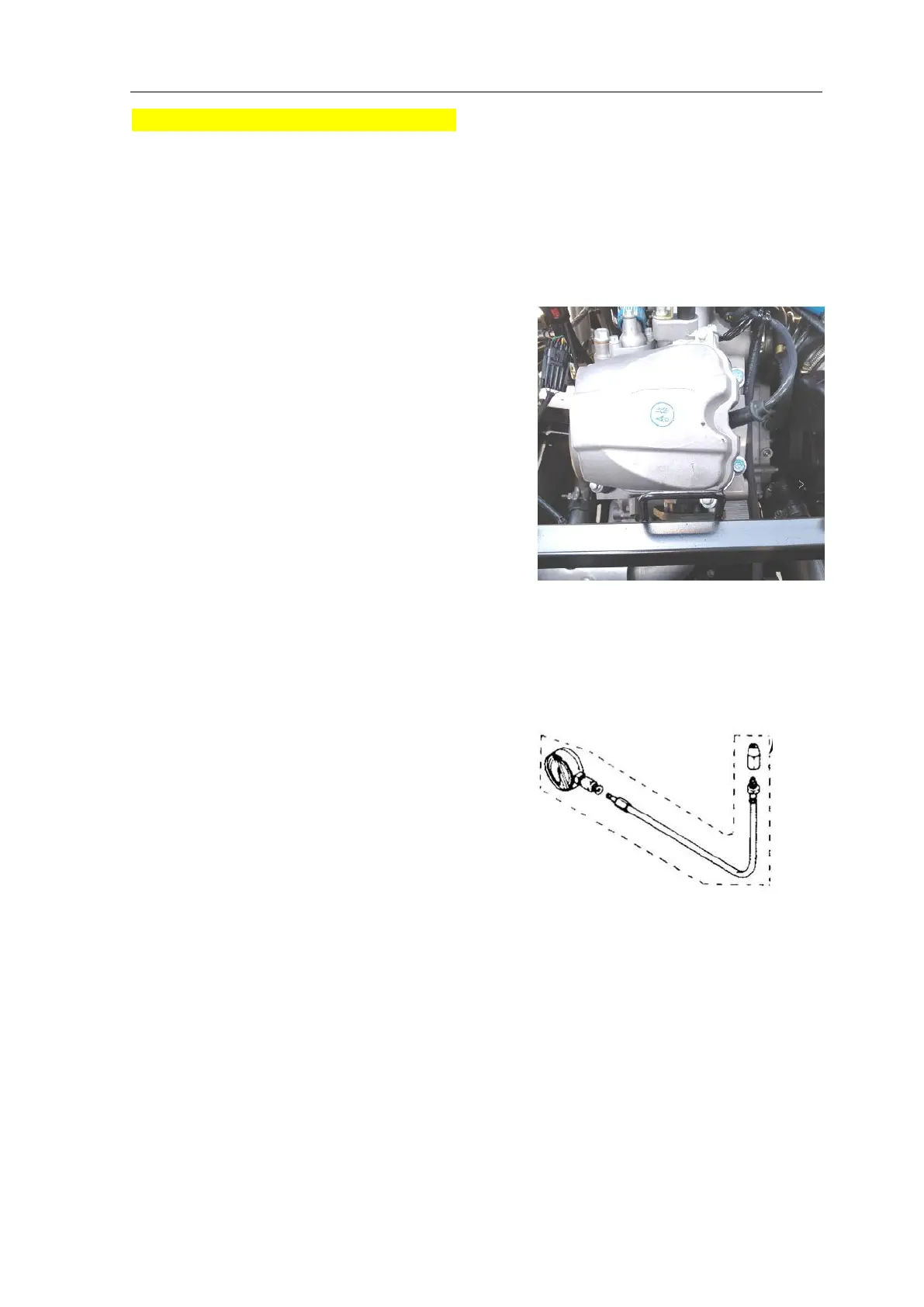

The compression pressure reading of a cylinder is a good indicator of its internal condition. The

decision to overhaul the cylinder is often based on results of a compression test.

Before measuring cylinder pressure, ensure installation and tightening of cylinder cap bolt with

designated torque and reasonable clearance of valve.

Standard cylinder pressure: 0.9~1.2Mpa(130.5PSI~174PSI)

Too low cylinder pressure may cause the

following:

Excessive wear to cylinder;

Wear to piston or piston ring;

Blockage of piston ring in groove;

Close valve seat;

Damage to cylinder lining or faults of other parts

Measure engine compression pressure:

1. Warm up engine.

2. Ensure full charging of battery.

3. Lift the rear cargo bed.

4. Remove middle seat, seat back guard plate.

5. Remove spark plug cable.

6. Dismantle spark plugs.

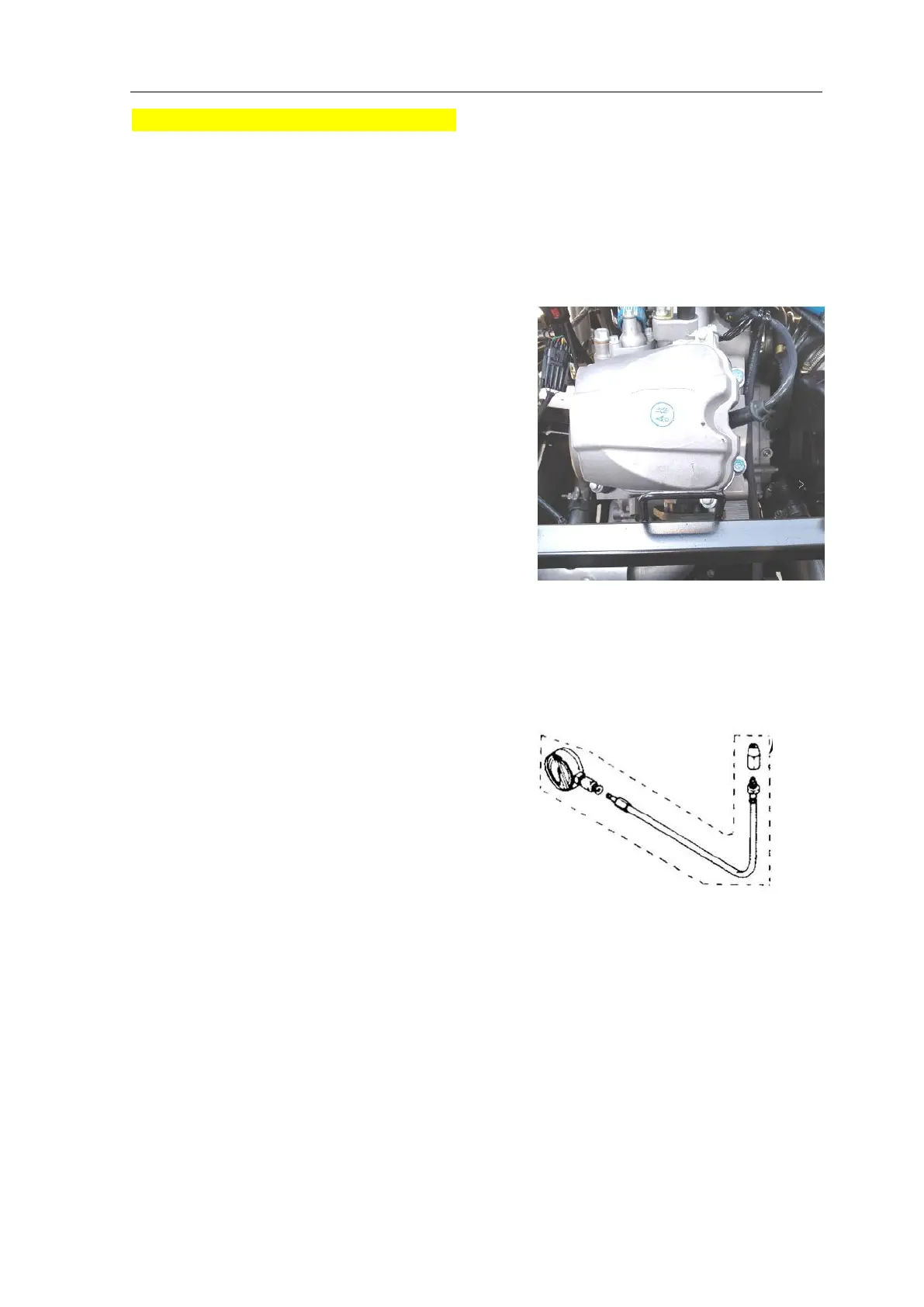

7. At spark plug hole, install cylinder

pressure meter.

8. Press button of start for several seconds.

Record indication of maximum cylinder

pressure.

Loading...

Loading...