3. ENGINE

3-

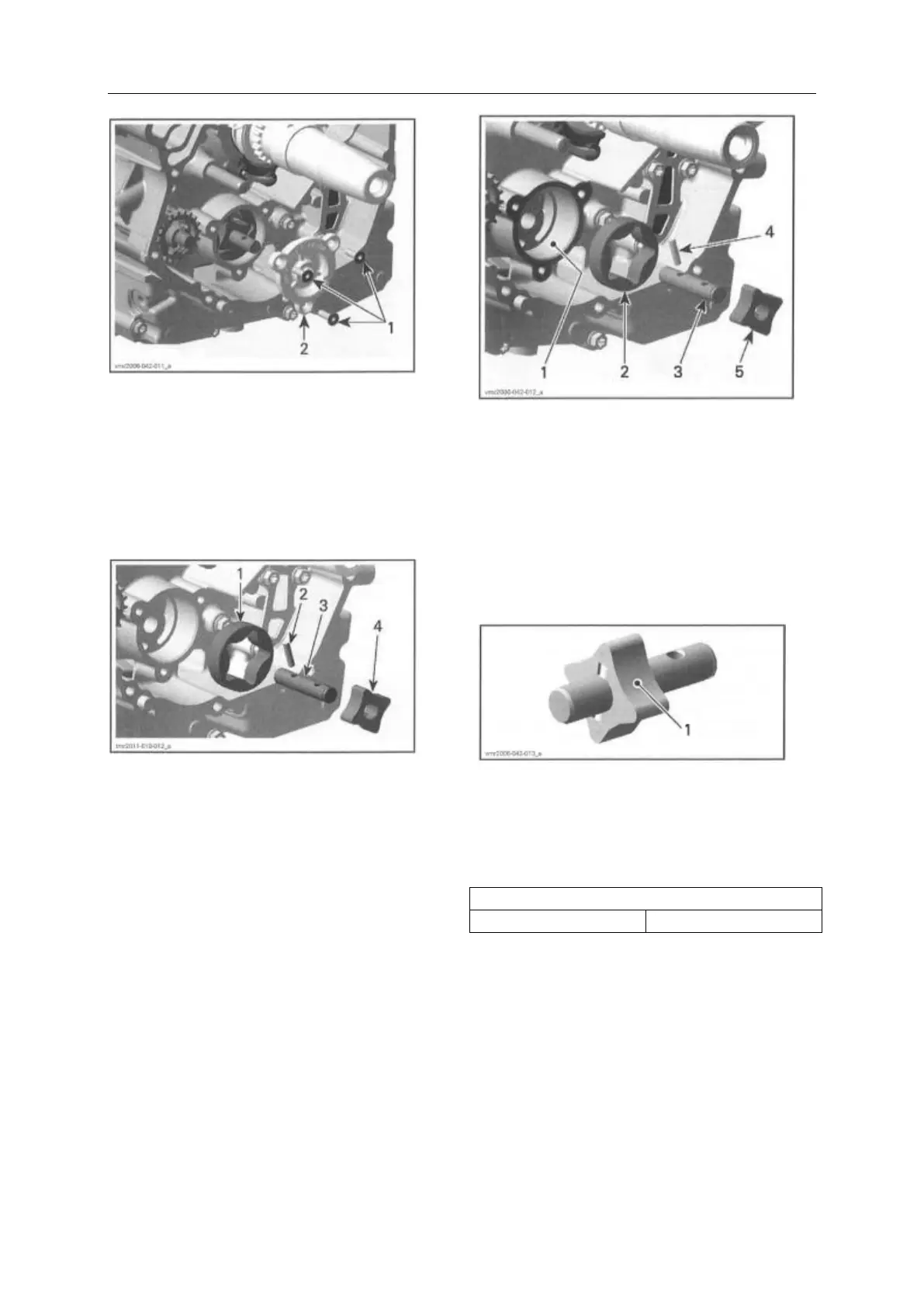

1. Retaining screws

2. Oil pump cover

3. Remove oil pump shaft with needle pin and

inner rotor.

4. Remove outer rotor.

1. Outer rotor

2. Needle pin

3. Oil pump shaft

4. Inner rotor

Oil Pump Inspection

Inspect oil pump and oil pump cover bore for

marks, scratches or other damages. Check for

scratches in crankcase between outer rotor and

oil pump bore. lf so, replace damaged parts.

Check oil pump cover for damages and for surface

straightness with a straightedge.

1. Oil pump bore

2. Outer rotor

3. Oil pump shaft

4. Needle pin

5. Inner rotor

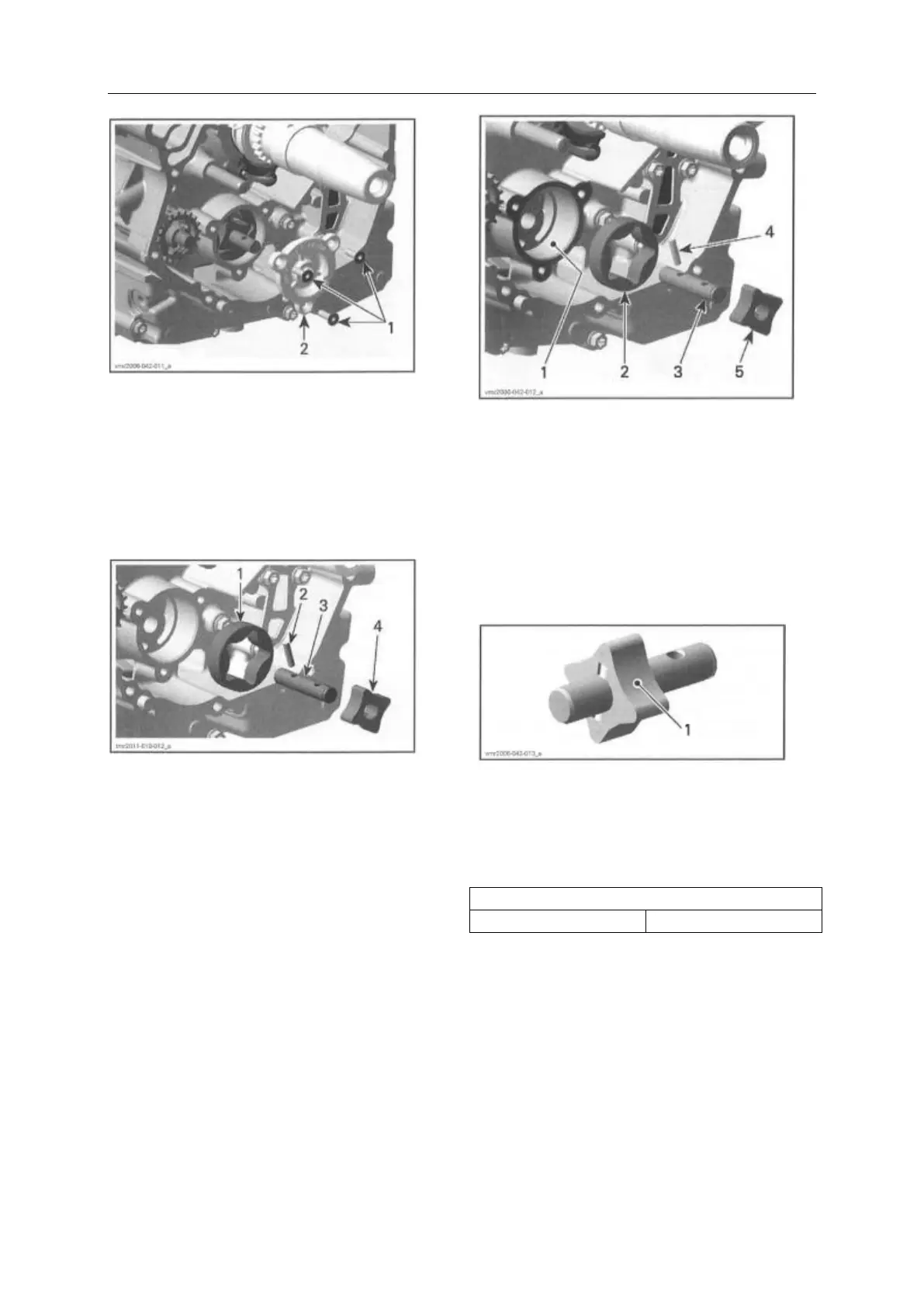

Check inner rotor for corrosion pin holes or other

damages. If so, replace oil pump shaft assembly.

1. Pittings on the teeth

Using a feeler gauge, measure the clearance of

inner and outer rotors as shown.

CLEARANCE OF INNER AND OUTER ROTOR

Loading...

Loading...