3. ENGINE

3-

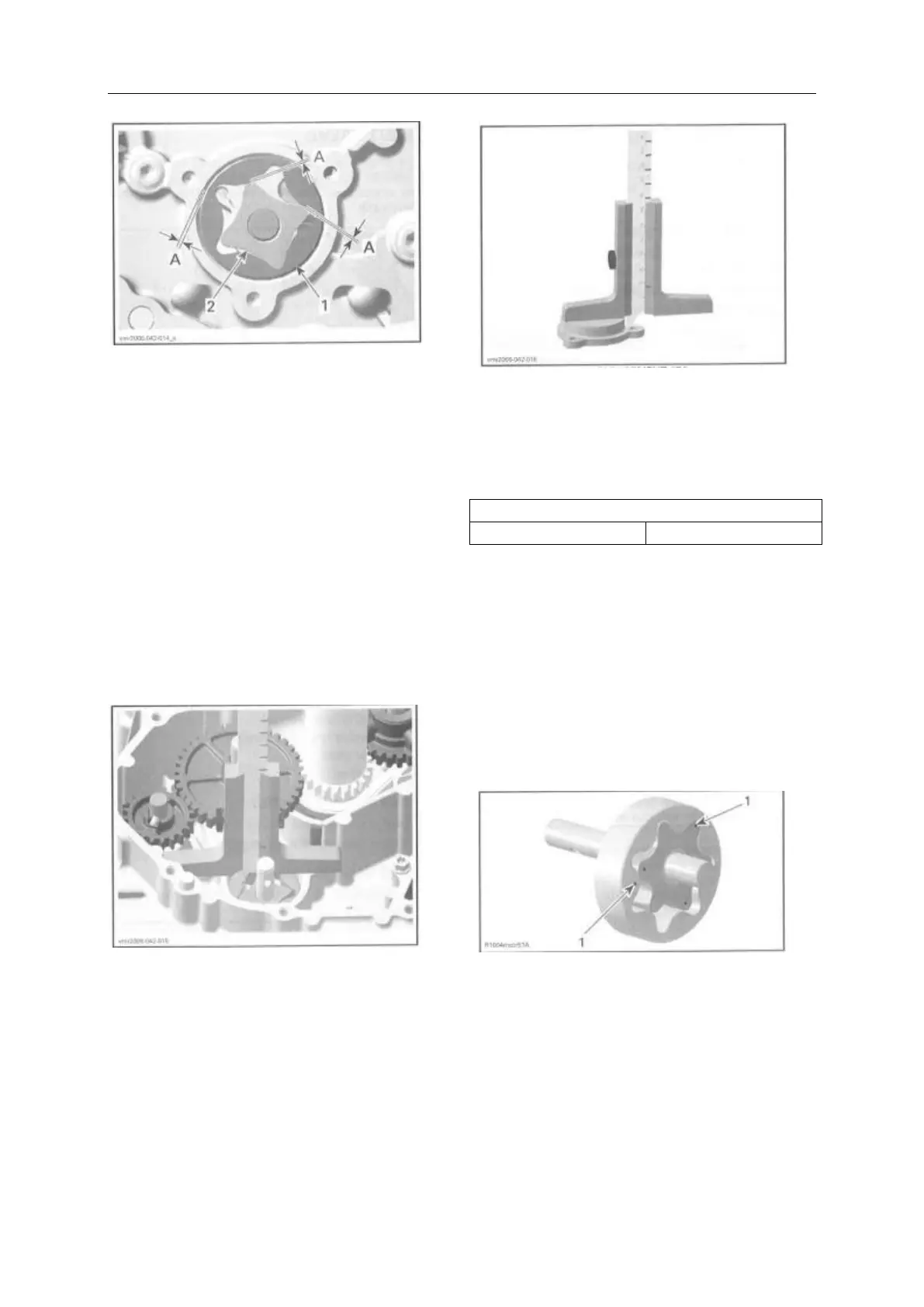

1. Outer rotor

2. Inner rotor

A. 0.25mm (.0098in)

If clearance of inner and outer rotors exceeds the

Tolerance, replace oil pump rotors. Ensure to also

check oil pump cover. If damaged, replace the

complete oil pump assembly.

If clearance between outer rotor and its bore in

crankcase exceeds the tolerance, replace the

complete oil pump rotors and/or the crankcase.

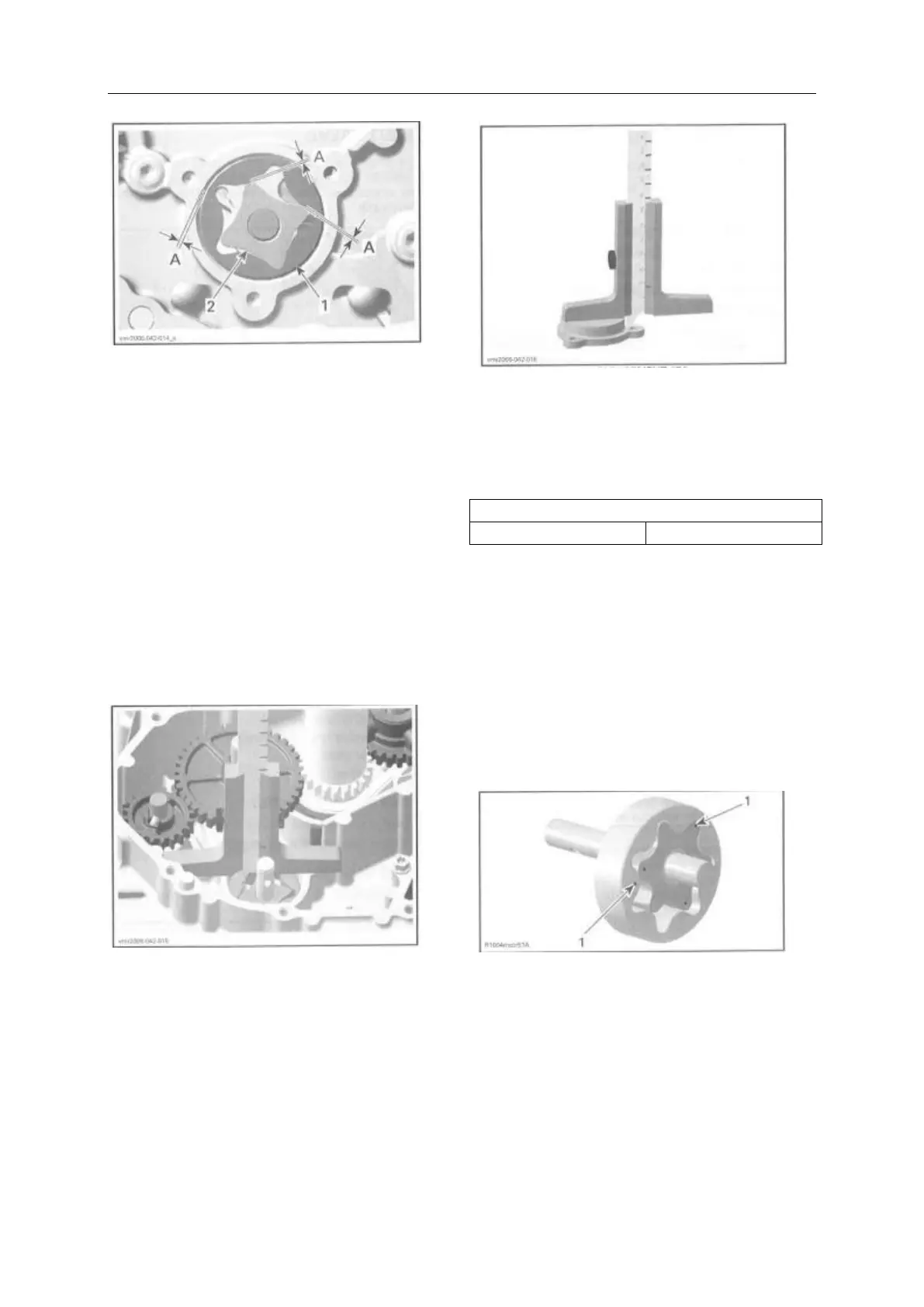

Using a depth gauge, measure the axial clearance

of the oil pump as shown.

OIL PUMP- MEASUREMENT "A″

OIL PUMP COVER- MEASUREMENT "B″

Substract measurement ''B" from measurement "A"

to obtain axial clearance.

NOTE: When the axial clearance of the oil pump

shaft assembly increases, the oil pressure de-

creases.

Oil Pump Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

NOTE: When installing the oil pump rotors, make

sure both markings are on the outer side.

TYPICAL

1. Markings

After reinstallation of the remaining parts, check

for smooth operation of the oil pump assembly.

Oil Pump Final Test

After engine is completely reassembled, start

engine and make sure oil pressure is within

specifications (refer to ENGINE OIL PRESSIRE

in this subsection).

Loading...

Loading...