3. ENGINE

3-

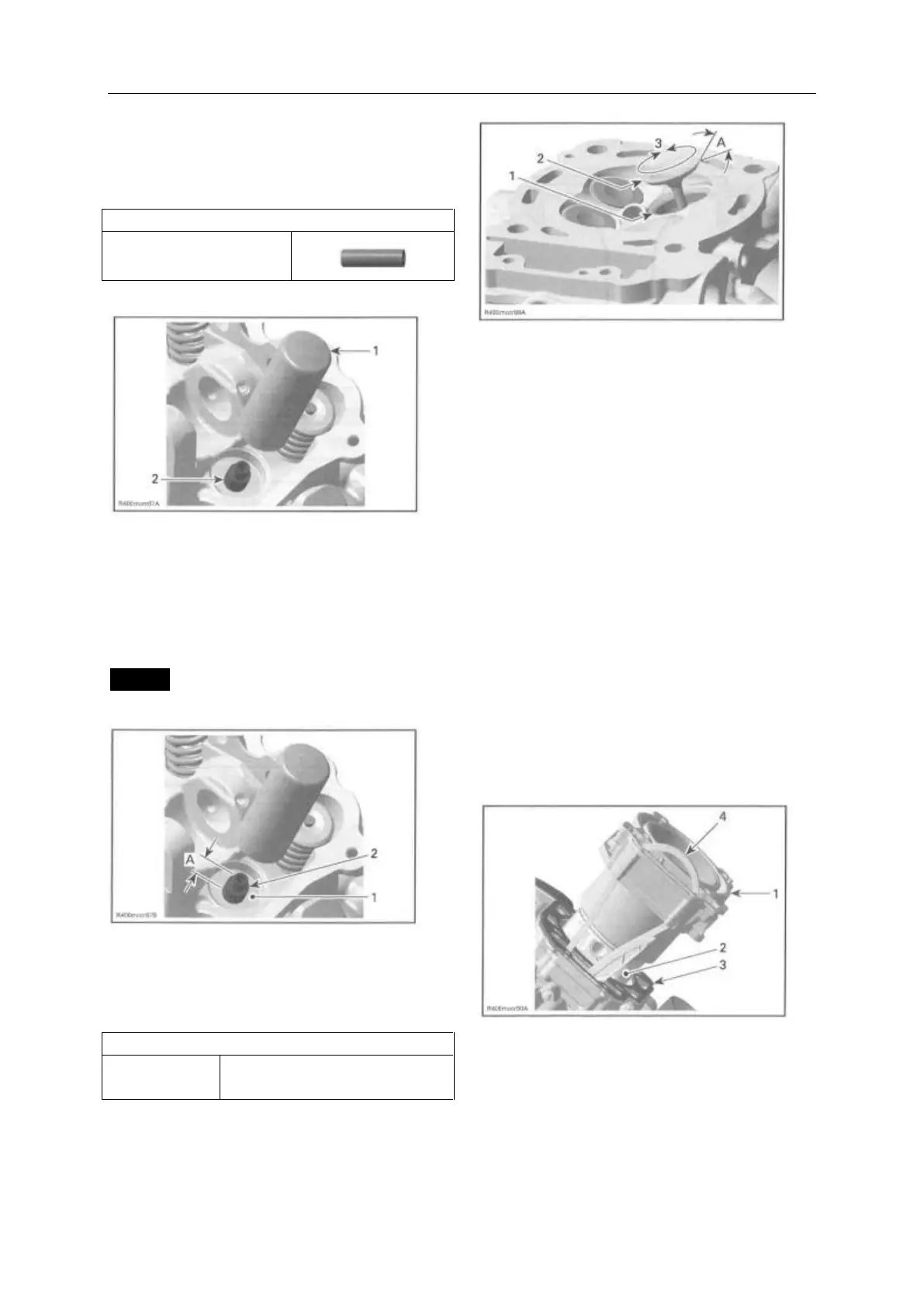

Clean the valve guide bore before reinstalling the

valve guide into cylinder head.

Install valve guide.

1. Valve guide installer

2. Valve guide

NOTE: Apply LOCTITE767 (ANTISEIZE

LUBRICANT) (P/N293 800 070) on valve guide

prior to install it into the cylinder head.

NOTICE Push valve guide in the cold cylinder

head as per following illustration.

1. Thrust surface of cylinder head

2. Valve guide

A. Measurement from thrust surface to valve guide

top

VALVE GUIDE(MEASUREMENT“A”)

14.00mm to14.40mm

(.5512 in to .5669 in)

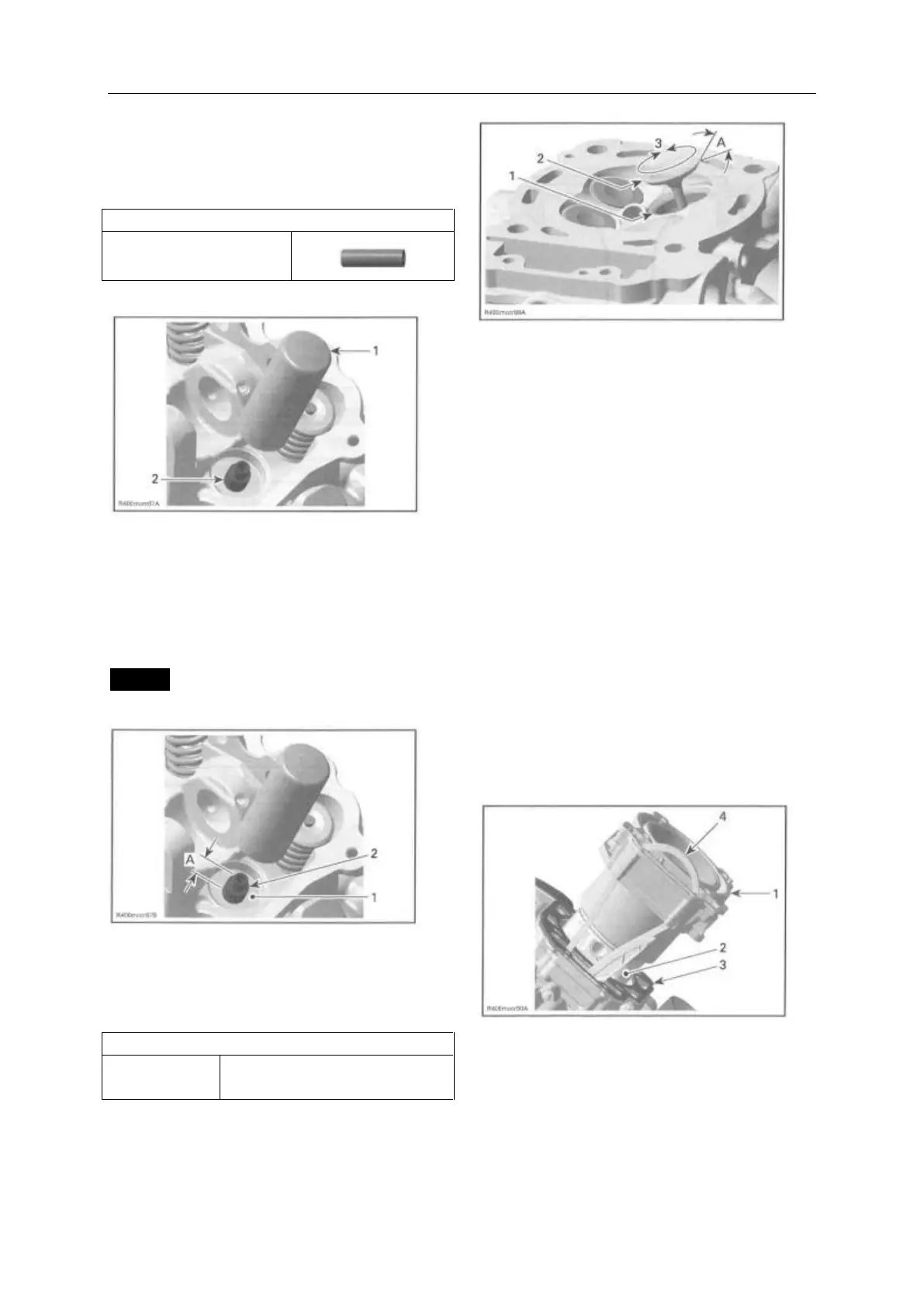

Apply some lapping compound to valve face and

work valve on its seat with a lapping tool.

1. Valve seat

2. Valve face (contact surface to valve seat)

3. Turn valve while pushing against cylinder head

A. Valve seat angle 45°

NOTE: Ensure to seat valves properly. Apply

marking paste to ease checking contact pattern.

Repeat procedure until valve seat/valve face fits

together.

CYLINDER

Cylinder Removal

Refer to TUMING CHAIN subsection and remove

the following parts:

- Timing chain tensioner

- Camshaft timing gear.

Remove the cylinder head (see CYLINDER

HEAD in this subsection).

Pull cylinder.

Discard cylinder base gaskets.

1. Cylinder

2. Piston assembly

3. Cylinder base gasket

4. Camshaft timing chain

Loading...

Loading...