3. ENGINE

3-

Cylinder Inspection

Check cylinder for cracks, scoring and wear ridges

on the top and bottom of the cylinder. If so, replace

cylinder.

Cylinder Taper

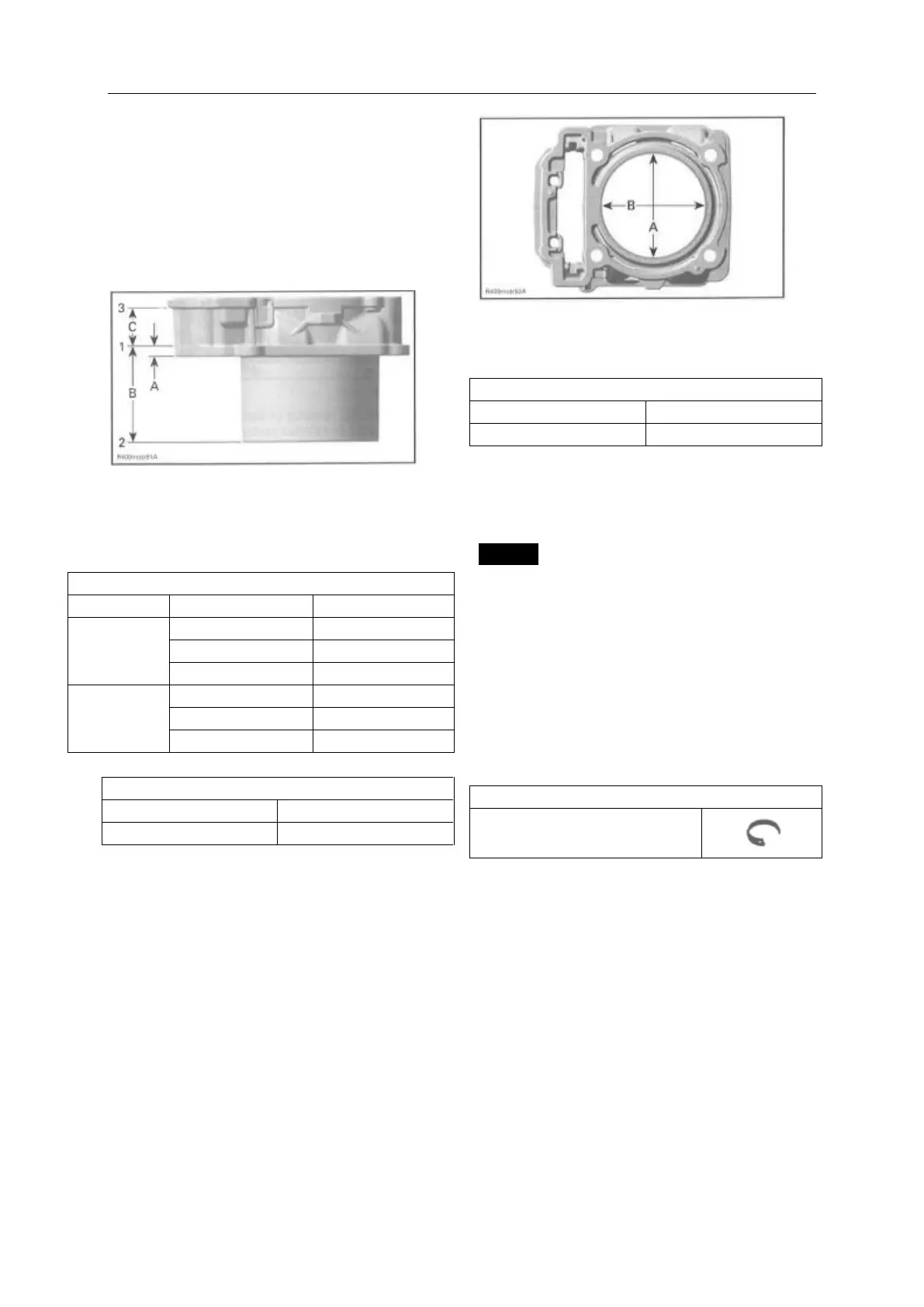

Measure cylinder bore at3 recommended positions.

A. First measurement (from cylinder bottom)

B. Second measurement

C. Third measurement

CYLINDER TAPER MEASUREMENTS

CYLINDER TAPER SPECIFICATION

Distance between measurements should not exceed

the service limit mentioned above. Otherwise,

replace cylinder and piston rings.

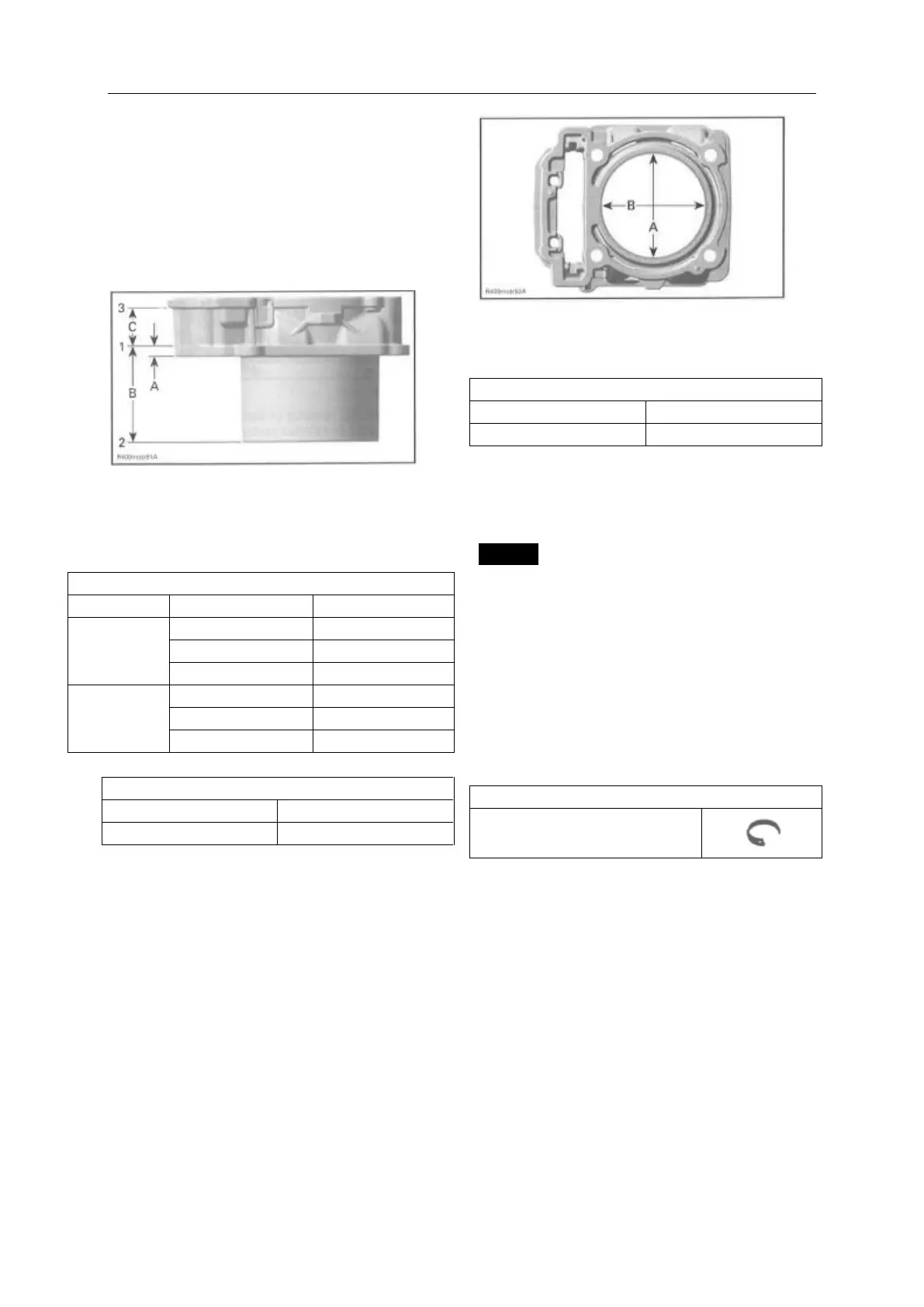

Cylinder Out of Round

Measure cylinder diameter in piston axis direction

from top of cylinder . Take another measurement

90° from first one and compare .

NOTE: Take the same measuring points like

described in CYLINDER TAPER above.

A. Perpendicular to crankshaft axis

B. Parallel to crankshaft axis

Cylinder Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

NOTICE Always replace cylinder base gasket

before installing the cylinder.

NOTE: Make sure piston rings are properly spaced,

refer to PISTION in this subsection.

Apply engine oil:

- In the bottom area of the cylinder bore

- On the piston rings

- On the compressor tool.

Compress piston rings.

First mount cylinder 2.

NOTE: The cylinder can not be pushed fully over

the piston unless the piston is located at TDC.

Then remove the CRANKSHAFT LOCKING

BOLIT (P/N529 035 617).

Crank the engine further and position piston1 at

TDC.

Mount cylinder 1.

Put timing chain through the chain pit then put the

cylinder in place.

Loading...

Loading...