3. ENGINE

3-

CORRECT POSITION OF THE PISTON CIRCLIP

PISTON RINGS

Ring Removal

Remove the piston (see PISTON in this

subsection).

Ring Inspection

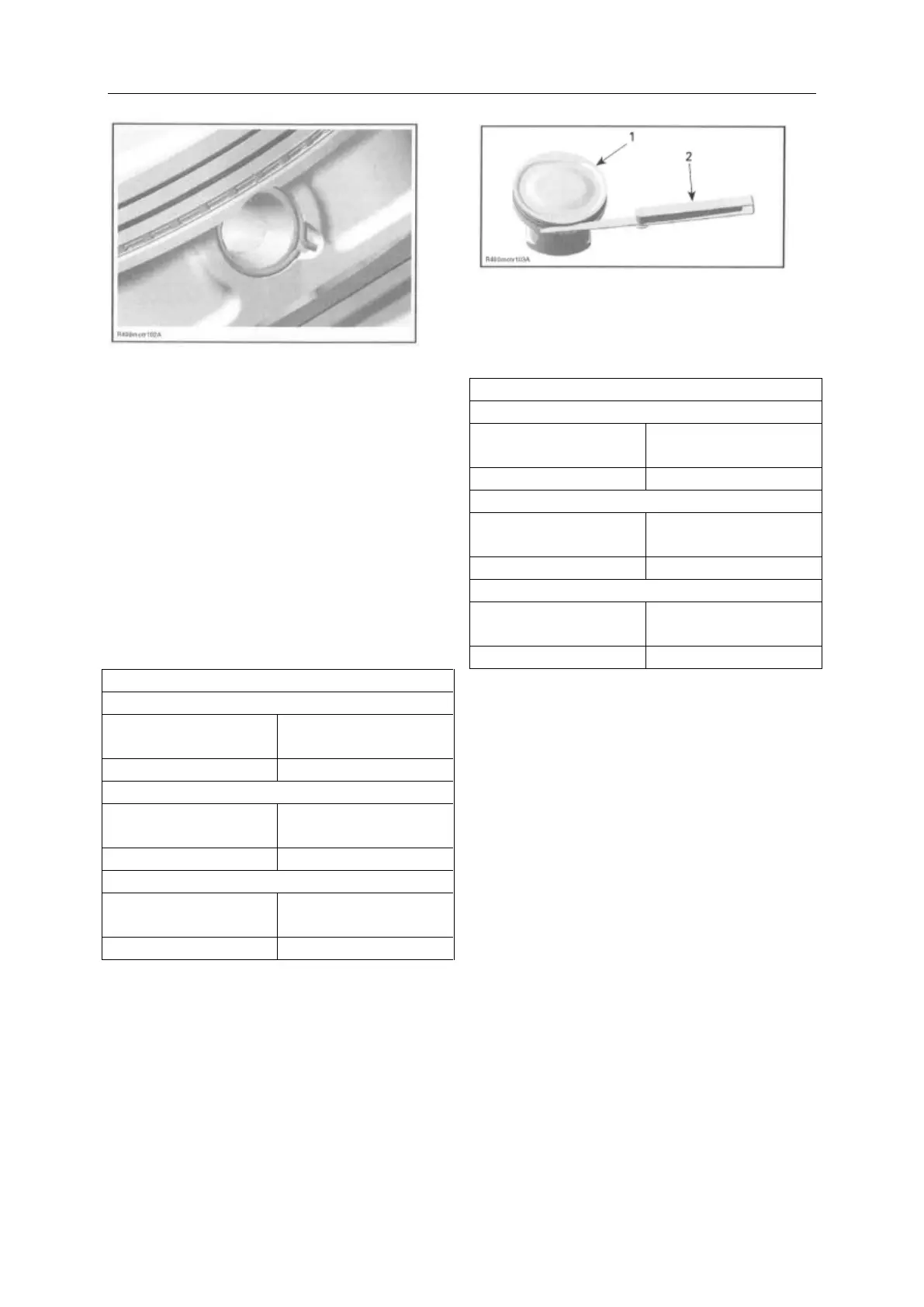

Ring/Piston Groove Clearance

Using a feeler gauge measure each ring/piston

groove clearance . If the clearance is too large, the

piston and the piston rings should be replaced.

0.03mm to 0.07mm

(.0012in to.0028in)

0.02 mm to 0.06mm

(.0008in to.0024in)

0.01 mm to 0.18mm

(.0004in to.0071 in)

1. Piston

2. Feeler gauge

Ring End Gap

RING/PISTON GR00VE CLEARANCE

0.20 mm to 0.40 mm

(.008in to.016in)

0.20 mm to 0.40mm

(.008in to.016in)

0.20 mm to 0.70mm

(.008in to.028in)

To measure the ring end gap place the ring in the

cylinder in the area of 8mmto16mm (5/16in

to5/8in) from top of cylinder.

NOTE: In order to correctly position the ring in the

cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring if gap exceeds above described specified

tolerance.

Ring Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

NOTE: Use a ring expander to prevent breakage

during installation. The oil ring must be installed

by hand.

NOTE: First install spring and then rings of oil

scraper ring.

Install the oil scraper ring first, then the lower

compression ring with the word “N” and “TOP”

facing up, then the upper compression ring with

the word “N” and “TOP” facing up.

Loading...

Loading...