710.1760.00.04-05 22/05/2014

32

Wait at least 15 minutes before removing the protective panels so that the chiller can cool

down. Certain internal components have a very high and dangerous operating temperature!

Never open the sealed cooling assembly (compressor, evaporator and condenser) if there may

be any refrigerant or lubricating oil present!

Never carry out any welding or soldering on the cooling system when it contains refrigerant in order to

avoid the risk of generating toxic substances.

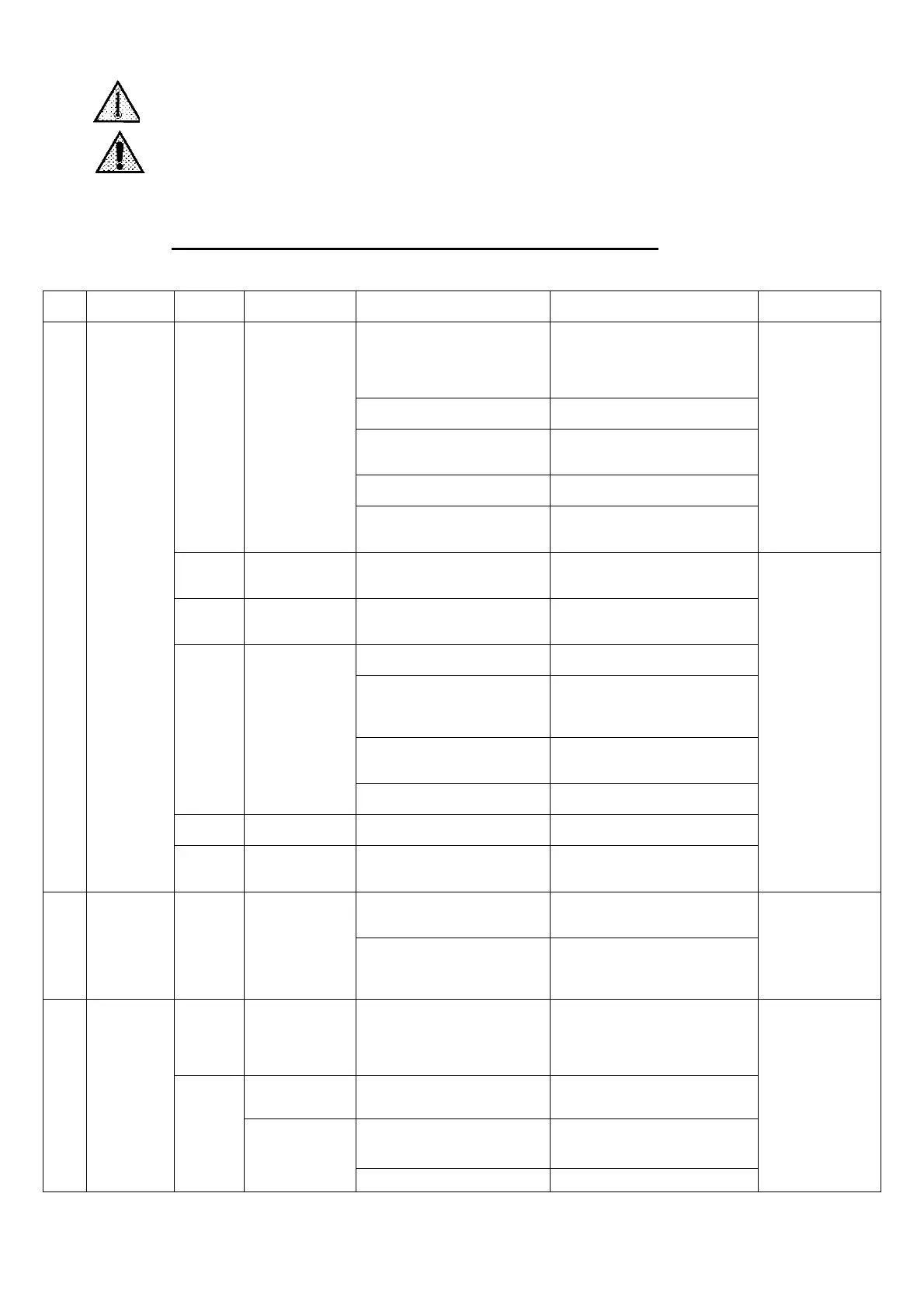

9.1 POSSIBLE ALARM SIGNALS AND THEIR RECTIFICATION

CONTROLLER TYPE “D” (CHW 11 TO CHW 36; CHG 08)

No. Device

status

Alarm

code

Alarm de-

scription

Possible cause Recommended remedy Fault

rectification (*)

1

Pump is

working,

fan and

compressor

are not

working

/

Refrigerant

high pressure

alarm

Ambient temperature too

high

Decrease ambient tempera-

ture, increasing ventilation of

the room, removing heat

sources or repairing the unit

from the direct rays of sun

M after reset

high pressure

switch using but-

ton on it if pre-

sent

Dirty condenser

Clean the condenser as de-

scribed in maintenance

Fan is not working fine or

the sense of rotation is not

correct

Check fuse of the fan, and

right rotation

Required cooling capacity is

higher than nominal

Decrease the required cooling

capacity

Air filter dirty (only for units

with this kind of option)

Dismount the filter from the

unit and clean it with air or

with water

OFF

Unit is in Off by

remote ON/OFF

Remote ON/OFF contact is

open or internal bridge re-

moved

Check bridge ROO and close

the contact

A

OFF Unit in stand by

The unit is energized but not

switched on

Follow procedure to start up

the unit using button on

controller

LA2

Anti-freeze

alarm

Percentage of antifreeze too

low

Add antifreeze to the liquid

Set point is too low for actu-

al system

If possible increase set point,

or check combination of flow,

temperature and antifreeze

percentage

Liquid flow too low

Check right rotation of pump

and possible obstruction on

liquid circuit

Dirty evaporator

Clean evaporator and in case

contact service

P1

Sensor SL de-

fective

Probe can be defective or

not well connected

Check connection and in case

change probe

HA

High liquid

temperature

alarm

Compressor switched off by

internal protection

Contact a technician

2

Pump is not

working,

fan and

compressor

are working

Pump is

blocked

The gear of the pump is

blocked by dusty or corro-

sion

Try to move the axe of the

pump and after that switch on

again

A

The motor of the pump is

internally protected

Switch off the unit for one hour

and try again after check the

axe is not blocked and there

are no liquid obstruction

3

Pump, fan

and

compressor

are not

working

LA2

Anti-freeze

alarm

Liquid flow too low Check no. 2 for pump problem

A

CA

Unit is in Off by

remote ON/OFF

Remote ON/OFF contact is

closed

Check bridge ROO and open

the contact

digital input

alarm

Liquid flow too low

Check right rotation of the

pump and possible obstruction

on liquid circuit

Liquid in the tank too low Fill the tank

Loading...

Loading...