52

Setting Output Specifications Section 3-5

3-5 Setting Output Specifications

The following table shows the parameters related to outputs. Each of the

parameters is described in detail following the table.

(

●: Supported)

3-5-1 Control Periods

• Set the output periods (control periods). Though a shorter period provides

better control performance, it is recommended that the control period be

set to 20 seconds or longer for a relay output to preserve the service life

of the relay. After the settings have been made in the initial setup, readjust

the control period, as required, by means such as trial operation.

• Set the control periods in the Control Period (Heating) and Control Period

(Cooling) parameters in the initial setting level. The default is 20 seconds.

• The Control Period (Cooling) parameter is used only for heating/cooling

control.

• When the control output is used as a current output or linear voltage out-

put, the Control Period settings cannot be used.

• The control period can be set for standard models only.

3-5-2 Direct and Reverse Operation

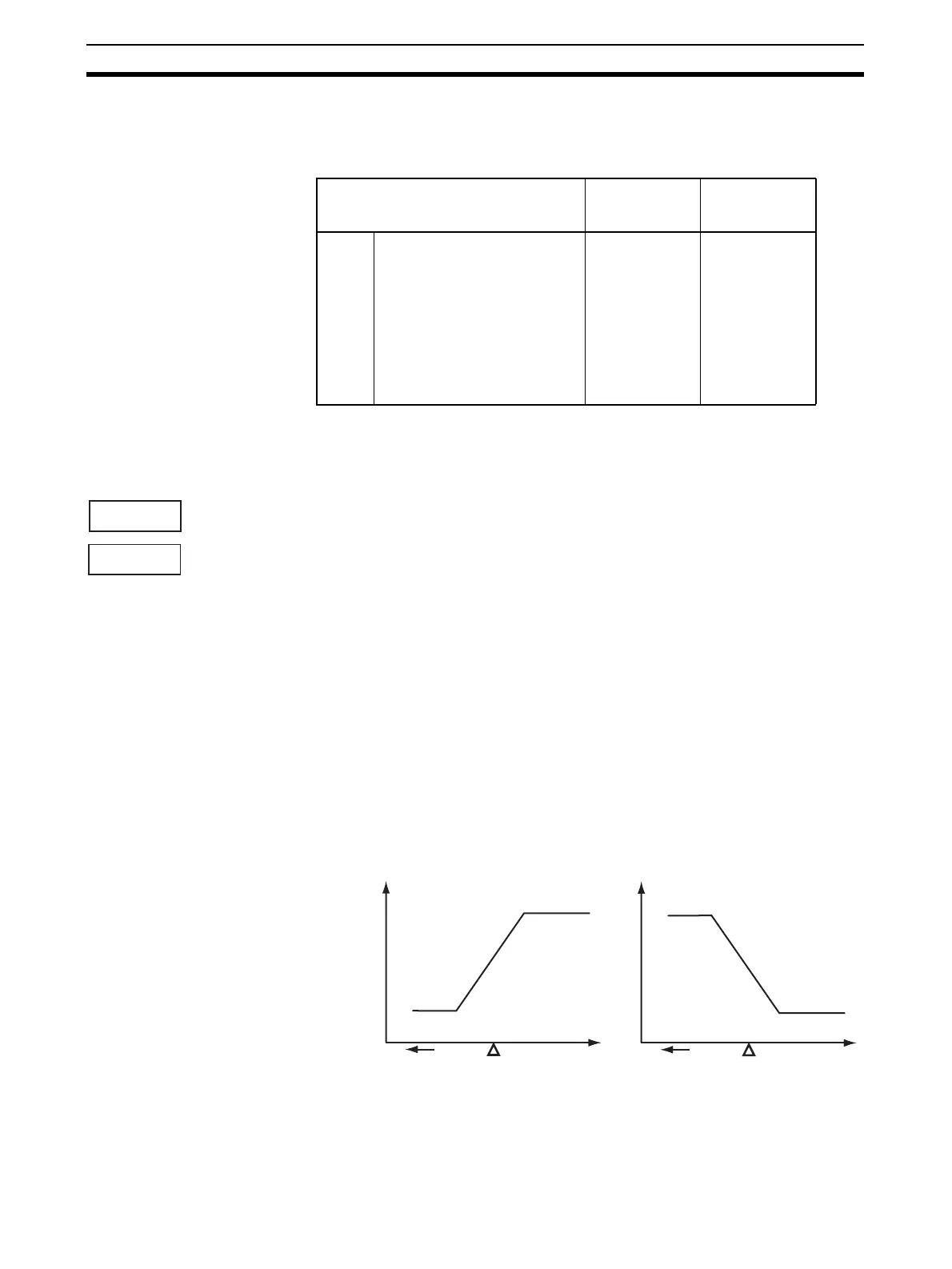

• Direct operation increases the manipulated variable whenever the pro-

cess value increases. Reverse operation decreases the manipulated vari-

able whenever the process value increases.

Parameter Standard

models

Position-

proportional

models

cp Control Period (Heating) ●

c-cp Control Period (Cooling) ●

orev Direct/Reverse Operation ●●

out1 Control Output 1 Assignment ●

out2 Control Output 2 Assignment ●

sub1 Auxiliary Output 1 Assignment ●●

sub2 Auxiliary Output 2 Assignment ●●

sub3 Auxiliary Output 3 Assignment ●

cp

c-cp

Control Period

(Heating)

Control Period

(Coolin

)

100%

0%

100%

0%

Manipulated variable Manipulated variable

Low

temperature

Set Value High

temperature

Low

temperature

Set Value High

temperature

Direct operation Reverse operation

Loading...

Loading...