2-103

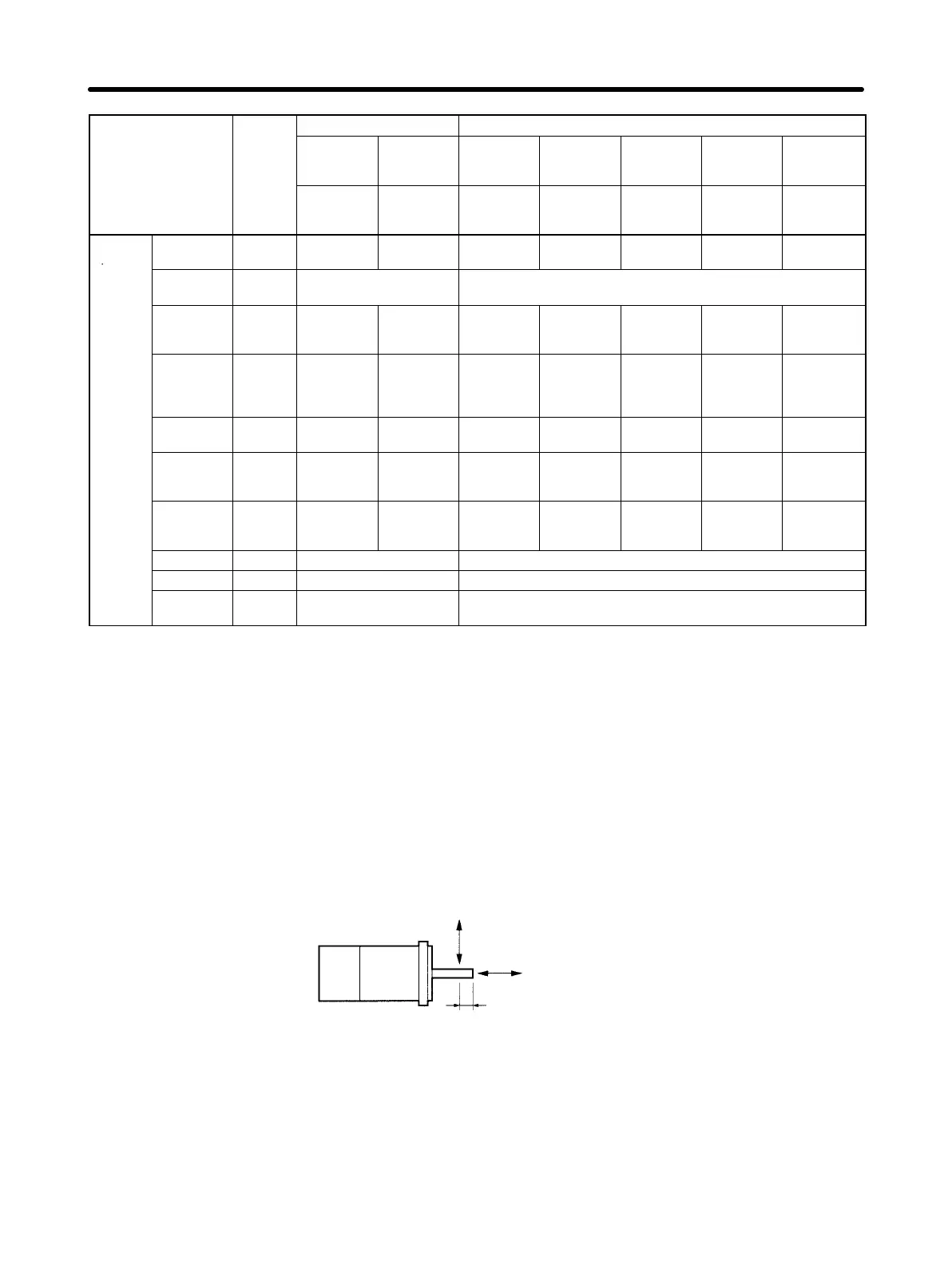

Item 200 V AC100 V ACUnitItem

R88M

-WP1K530

H

R88M

-WP75030

H

R88M

-WP40030

H

R88M

-WP20030

H

R88M

-WP10030

H

R88M

-WP20030

L

R88M

-WP10030

L

Unit

Item

R88M

-WP1K530

T

R88M

-WP75030

T

R88M

-WP40030

T

R88M

-WP20030

T

R88M

-WP10030

T

R88M

-WP20030

S

R88M

-WP10030

S

Unit

Brake

specifi-

Brake iner-

tia

kgSm

2

(GD

2

/4)

2.9 × 10

–6

1.09 × 10

–5

2.9 × 10

–6

1.09 × 10

–5

1.09 × 10

–5

8.75 × 10

–5

8.75 × 10

–5

cations

Excitation

voltage

V 24 V DC ±10% 24 V DC ±10%

Power con-

sumption

(at 20°C)

W 8.1 7.6 8.1 7.6 7.6 7.5 10

Current

consump-

tion (at

20°C)

A 0.34 0.29 0.34 0.29 0.34 0.31 0.42

Static fric-

tion torque

NSm

0.48 to 0.73 0.95 to 1.42 0.48 to 0.73 0.95 to 1.42 1.96 to 2.84 3.5 min. 7.1 min.

Attraction

time (See

note 3.)

ms 20 max. 20 max. 20 max. 20 max. 60 max. 20 max. 20 max.

Release

time (See

note 3.)

ms 40 max. 40 max. 40 max. 40 max. 20 max. 40 max. 40 max.

Backlash 1° (reference value) 1° (reference value)

Rating – Continuous Continuous

Insulation

grade

– Type F Type F

Note 1. The values for items marked by asterisks are the values at an armature winding temperature

of 100°C, combined with the Servo Driver. Other values are at normal conditions (20°C, 65%).

The momentary maximum torque shown above indicates the standard value.

Note 2. The brakes are the non-excitation operation type (released when excitation voltage is ap-

plied).

Note 3. The operation time is the measured value (reference value) with a surge killer (CR50500, by

Okaya Electric Industries co. LTD) inserted.

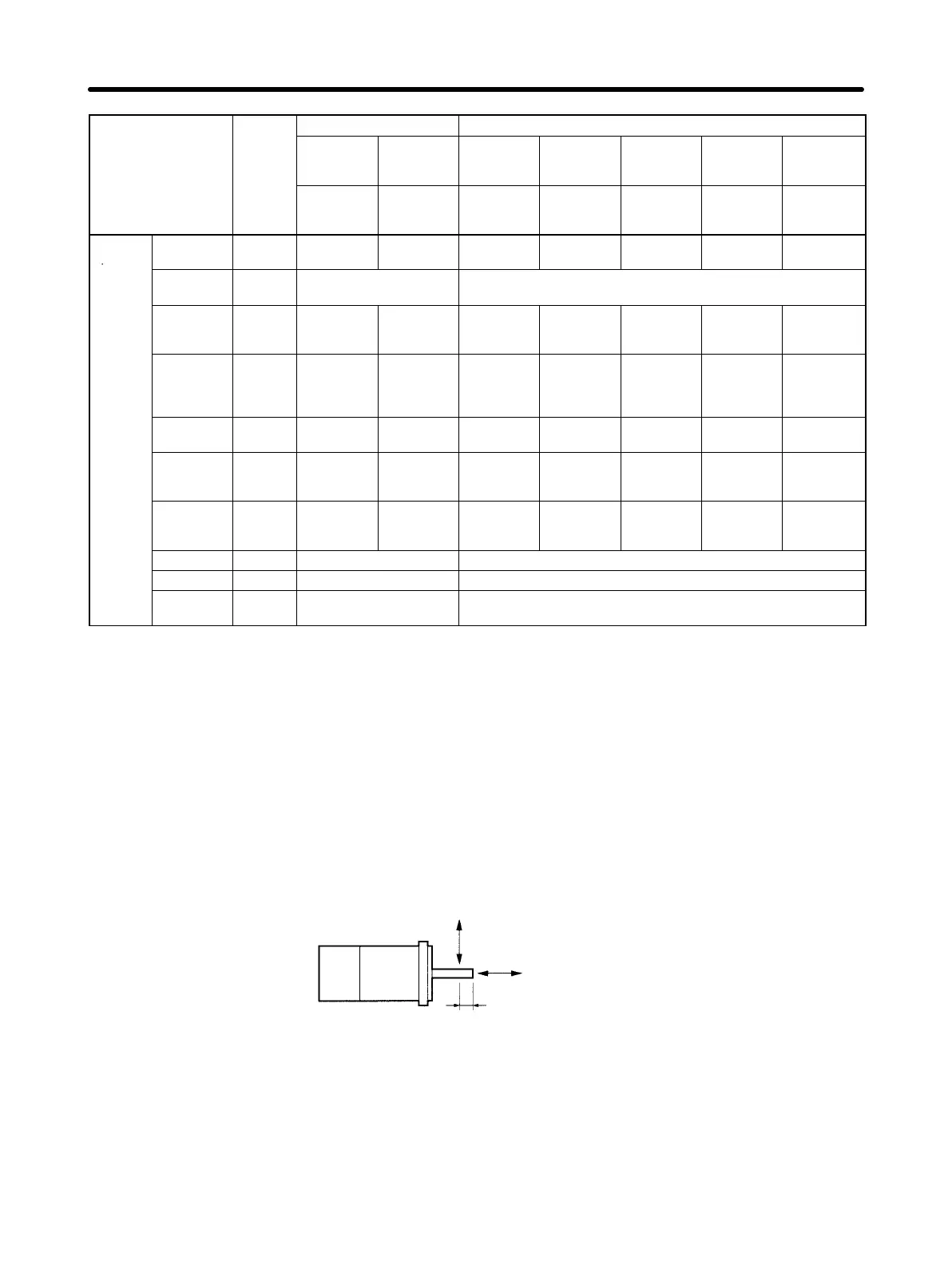

Note 4. The allowable radial and thrust loads are the values determined for a service life of 20,000

hours at normal operating temperatures.

Note 5. The value indicated for the allowable radial load is for the position shown in the following dia-

gram.

Radial load

5 mm

Thrust load

Note 6. Applicable Load Inertia

1) The drivable load inertia ratio (load inertia/rotor inertia) changes depending on the mechanical con-

figuration being driven and its rigidity. Highly rigid machines can operate with a large load inertia.

Select a Servomotor and verify operation.

2) If the dynamic brake is used frequently with a large load inertia, it may lead to burnout of the dynamic

brake resistor. Do not repeatedly turn the Servo ON and OFF with the dynamic brake enabled.

Standard Models and Specifications Chapter 2

Loading...

Loading...