Warnings for UL/cUL Marking

• Do not connect or disconnect wiring, or perform signal checks while the power supply is turned ON.

• The Inverter internal capacitor is still charged even after the power supply is turned OFF. To prevent

electrical shock, disconnect all power before servicing the Inverter. Then wait at least one minute after

the power supply is disconnected and all indicators are OFF.

• Do not perform a withstand voltage test on any part of the Inverter. This electronic equipment uses

semiconductors and is vulnerable to high voltage.

• Do not remove the Digital Operator or the blank cover unless the power supply is turned OFF. Never

touch the printed control board (PCB) while the power supply is turned ON.

• The Inverter is not suitable for use on a circuit capable of delivering more than 5,000 RMS symmetrical

amperes, 250 volts maximum (200-V-class Units) or 18,000 RMS symmetrical amperes, 480 V maxi-

mum (400-V-class Units).

• Take measures against overcurrent, overload, and overheating by using the Motor Protection Set-

tings.

CAUTION

Use 75°C copper wires or equivalent.

Low voltage wires shall be wired with Class I Wiring.

H Motor Protection Settings

Rated Motor Current (n036)

• Check the rated current on the motor nameplate and set the parameter.

• This parameter is used for the electronic thermal function for motor overload detection (OL1). By set-

ting the correct parameter, the overloaded motor will be protected from burning.

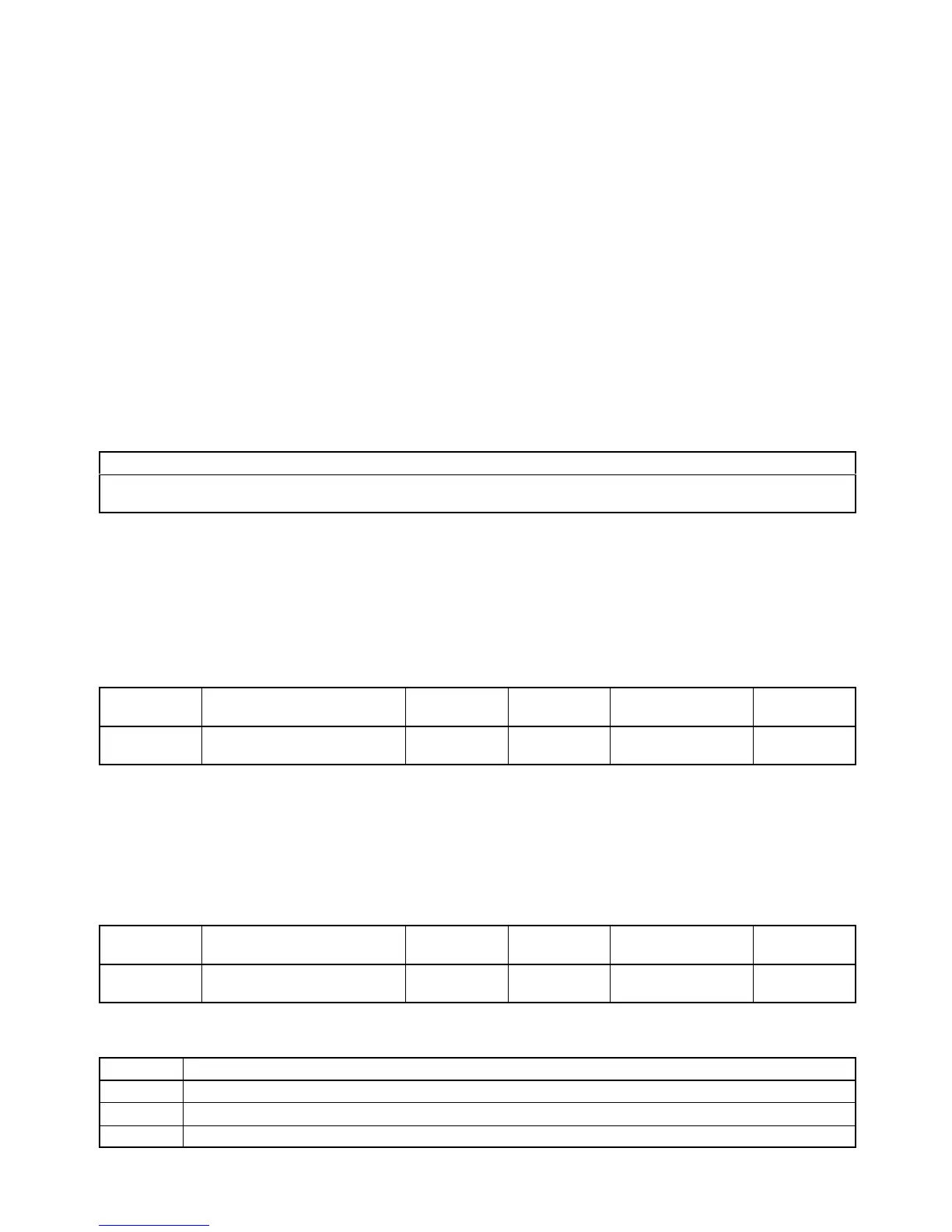

n036 Rated Motor Current Register

No.

0124 Hex Changes during

operation

No

Setting

range

0.0% to 150% (A) of rated

output current of Inverter

Unit of

setting

0.1 A Default setting (see note 1)

Note 1. The standard rated current of the maximum applicable motor is the default rated motor cur-

rent.

Note 2. Motor overload detection (OL1) is disabled by setting the parameter to 0.0.

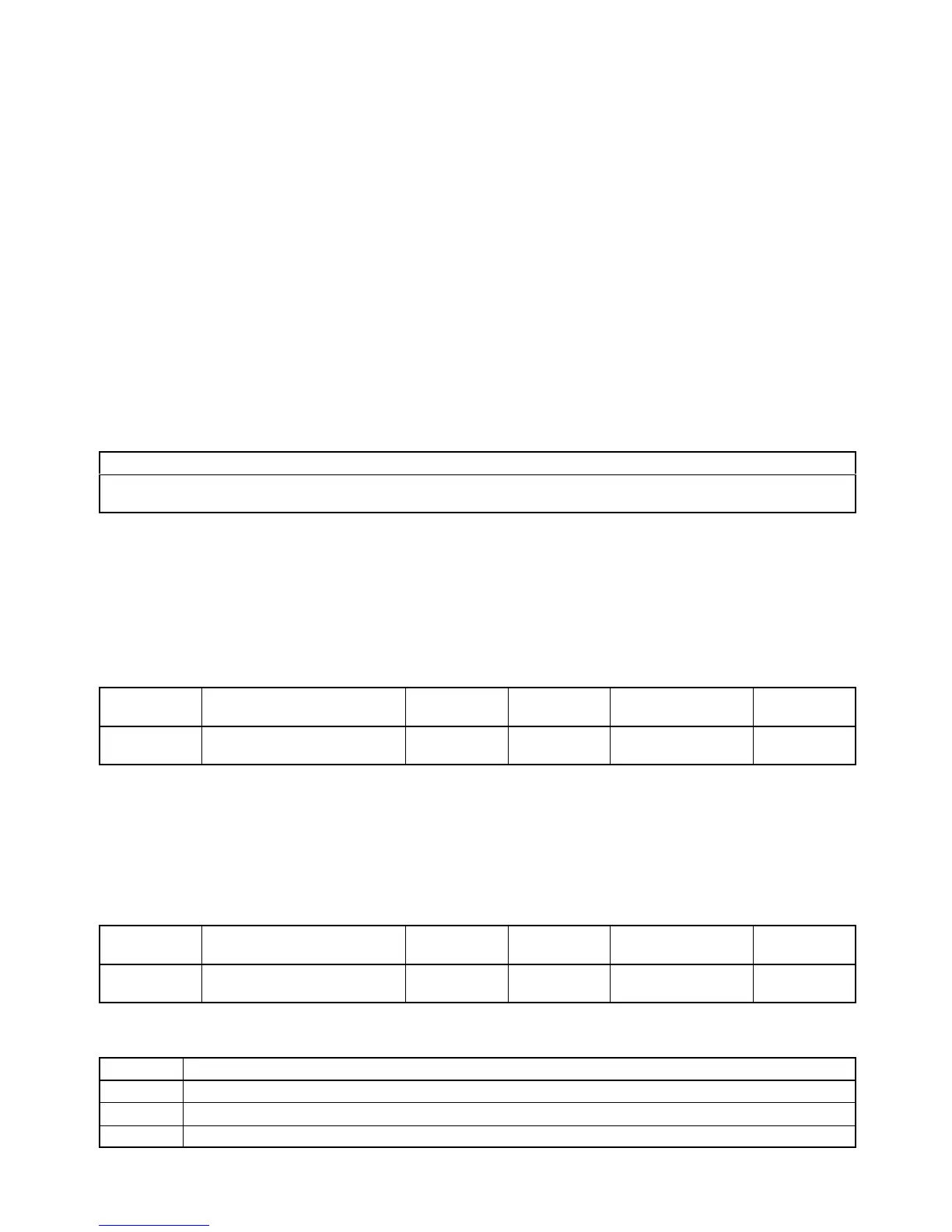

Motor Protection Functions (n037 and n038)

• This parameters setting is for motor overload detection (OL1).

n037 Motor Protection

Function Selection

Register

No.

0125 Hex Changes during

operation

No

Setting

range

0 to 2 Unit of

setting

1 Default setting 0

D Set Values

Value Description

0 Protection characteristics for general-purpose induction motors

1 Protection characteristics for Inverter-dedicated motors

2 No protection

Loading...

Loading...