Communication protocols

PROGRAMMING MANUAL 220

Revision 1.0

4.3.4 User-defined protocol

You can implement a user-defined communication protocol with these

commands:

/i

Example

Assume a set-up with:

• A Trajexia system with a TJ2-MC64.

• An OMRON Vision system F500.

• A connection from the serial port of the TJ2-MC64 to the F500. The

serial port uses RS232 (port 1) communication.

This program sends a Vision command through the serial port, reads the

response from the Vision system, writes it to VR variables and prints the

results in the Terminal window of Trajexia Tools.

' In the STARTUP program

' Setting RS232 port for the vision system

SETCOM(38400,8,1,0,1,0)

' In the application program

loop:

' Trigger, rising edge in virtual system

WAIT UNTIL IN(30)=0

WAIT UNTIL IN(30)=1

' Clear screen

PRINT CHR(27);"[2J"

' Clear buffer

GOSUB clear_buffer

' Send command to the serial port according to VR(10)

IF vision_command=v_measure THEN

PRINT #1, "M"

PRINT ">> M"

ELSEIF vision_command=v_date THEN

PRINT #1, "DATE"

PRINT ">> DATE"

ELSEIF vision_command=v_scene THEN

PRINT #1,"SCENE ";scene_n

PRINT ">> SCENE"

ENDIF

'Check response

GOSUB read_buffer

GOTO loop

read buffer:

count=0

resp_status=0

k=-1

TICKS=5000

REPEAT

IF KEY#1 THEN

count=count+1

GET#1, k

'PRINT k;count

TABLE(count,k)

'PRINT count

ENDIF

UNTIL TICKS<0 'OR k=13

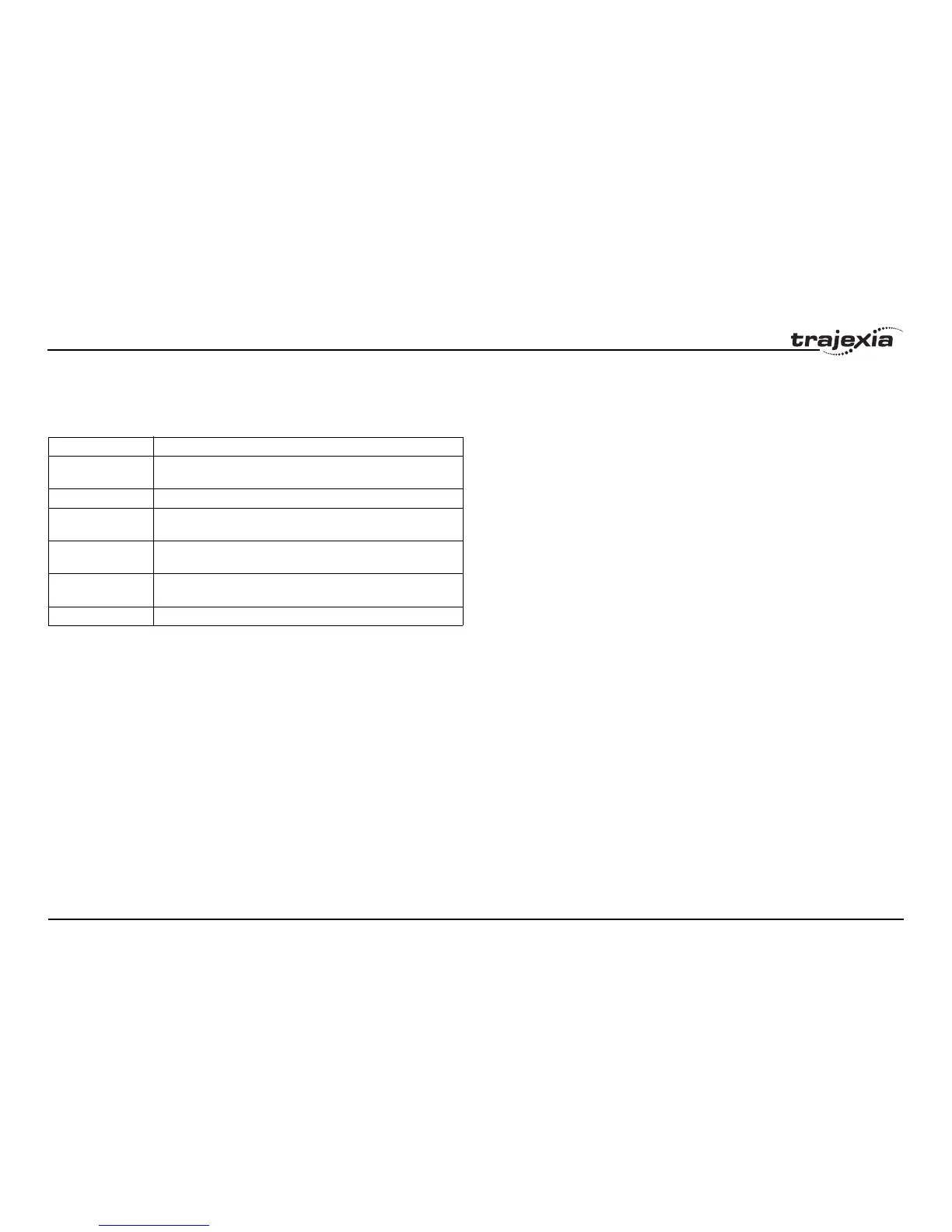

BASIC command Description

SETCOM SETCOM configures the serial communication port, and it enables

the Host Link protocols.

GET GET assigns the ASCII code of a received character to a variable.

INPUT INPUT assigns numerical input string values to the specified varia-

bles.

KEY KEY returns TRUE or FALSE, when a character has been received

or has not been received.

LINPUT LINPUT assigns the ASCII code of received characters to an array

of variables.

PRINT PRINT outputs a series of characters to a serial output device.

Loading...

Loading...