BASIC commands

PROGRAMMING MANUAL 17

Revision 1.0

3 BASIC commands

3.1 Categories

This section lists all BASIC commands divided by categories. The categories

are:

• Axis commands.

•Axis parameters.

• Communication commands and parameters.

• Constants.

• I/O commands, functions and parameters.

• Mathematical functions and operations.

• Program commands.

• Program control commands.

• Slot parameters and modifiers.

• System commands and functions.

• System parameters.

• Task commands and parameters.

The lists are quick reference guides only. A complete description of the

commands is given in alphabetical order in the next section.

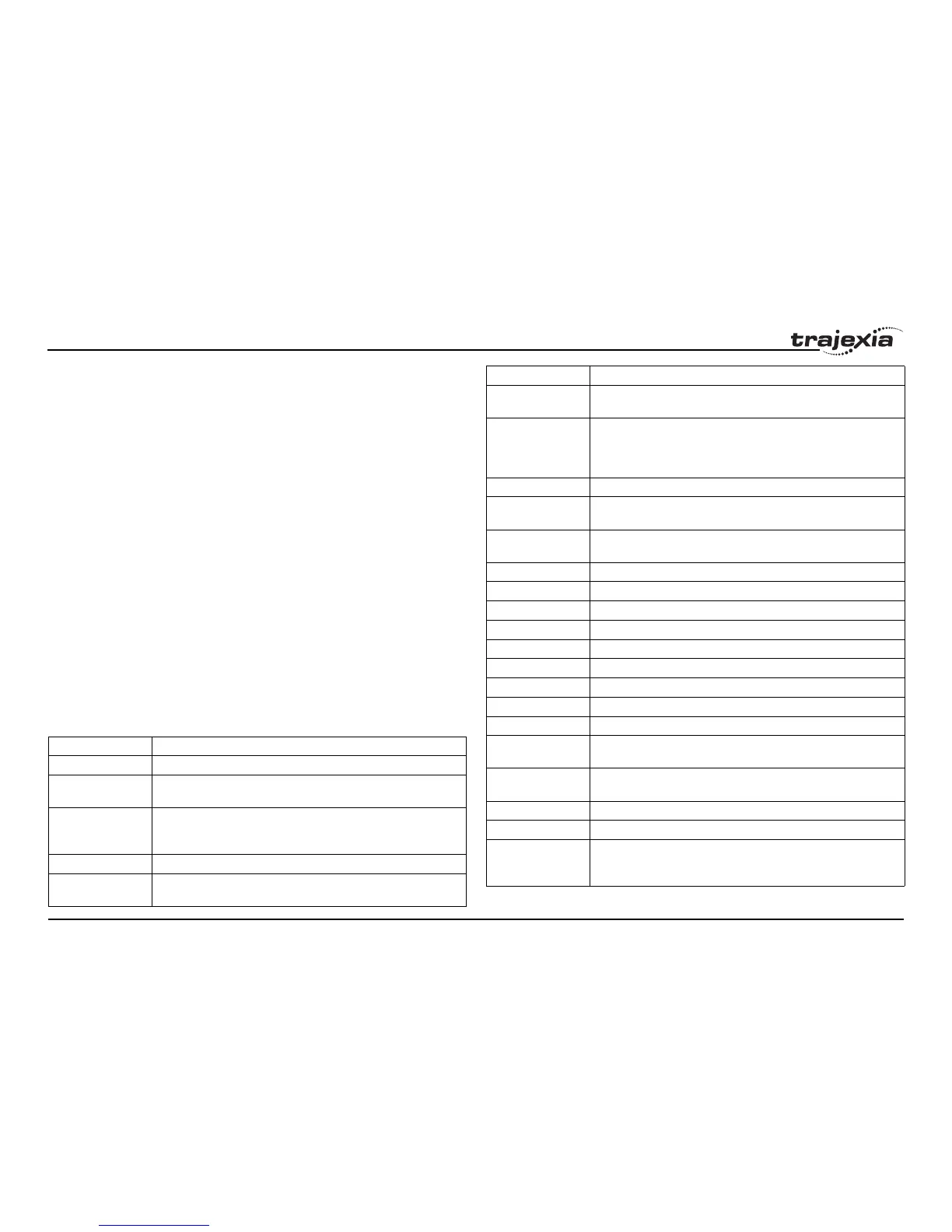

3.1.1 Axis commands

/i

Name Description

ACC Changes the ACCEL and DECEL at the same time.

ADD_DAC Sum to the DAC value of one axis to the analogue output of the

base axis.

ADDAX Sets a link to a superimposed axis. All demand position movements

for the superimposed axis will be added to any moves that are cur-

rently being executed.

BACKLASH Allows the backlash compensation to be loaded.

BASE Used to set the base axis to which the commands and parameters

are applied.

CAM Moves an axis according to values of a movement profile stored in

the TABLE variable array.

CAMBOX Moves an axis according to values of a movement profile stored in

the TABLE variable array. The motion is linked to the measured

motion of another axis to form a continuously variable software gear-

box.

CANCEL Cancels the move on an axis.

CONNECT Connects the demand position of an axis to the measured move-

ments of an other axis to produce an electronic gearbox.

DATUM Performs one of 7 origin search sequences to position an axis to an

absolute position or reset a motion error.

DEFPOS Defines the current position as a new absolute position.

DISABLE_GROUP Groups axes together for error disabling.

DRIVE_ALARM Monitors the current alarm.

DRIVE_CLEAR Clears the alarm status of the Servo Drive.

DRIVE_READ Reads the specified parameter of the Servo Drive.

DRIVE_RESET Resets the Servo Drive.

DRIVE_WRITE Writes a specific value to the specified parameter of the Servo Drive.

ENCODER_READ Reads a parameter of the EnDat absolute encoder.

ENCODER_WRITE Writes to a parameter of the EnDat absolute encoder.

FORWARD Moves an axis continuously forward at the speed set in the SPEED

parameter.

MECHATROLINK Initializes MECHATROLINK-II bus and performs various operations

on MECHATROLINK-II stations connected to the bus.

MHELICAL Interpolates 3 orthogonal axes in a helical move.

MHELICALSP Forced speed version of the MHELICAL command.

MOVE Moves one or more axes at the demand speed, acceleration and

deceleration to the position specified as increment from the current

position.

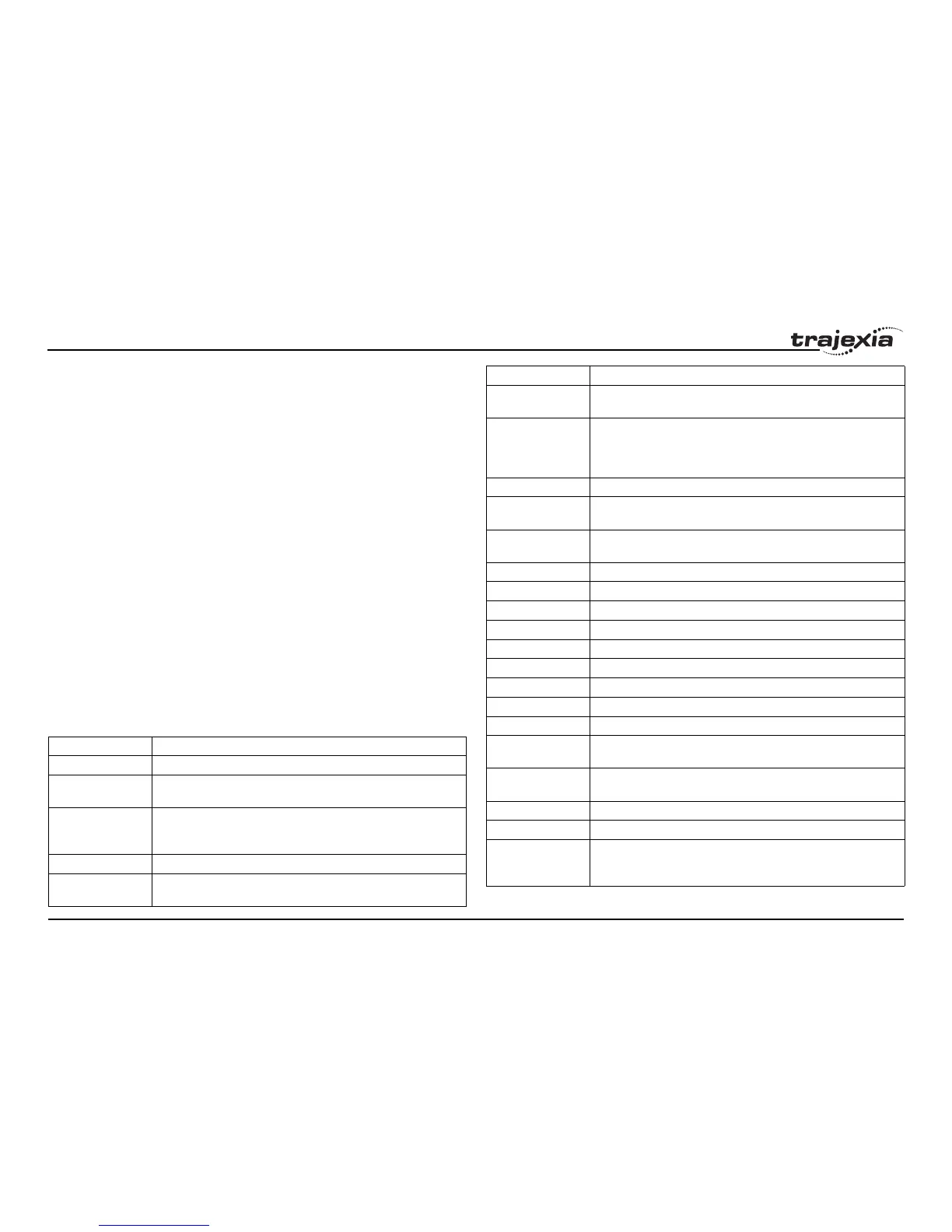

Name Description

Loading...

Loading...