Examples and tips

PROGRAMMING MANUAL 340

Revision 1.0

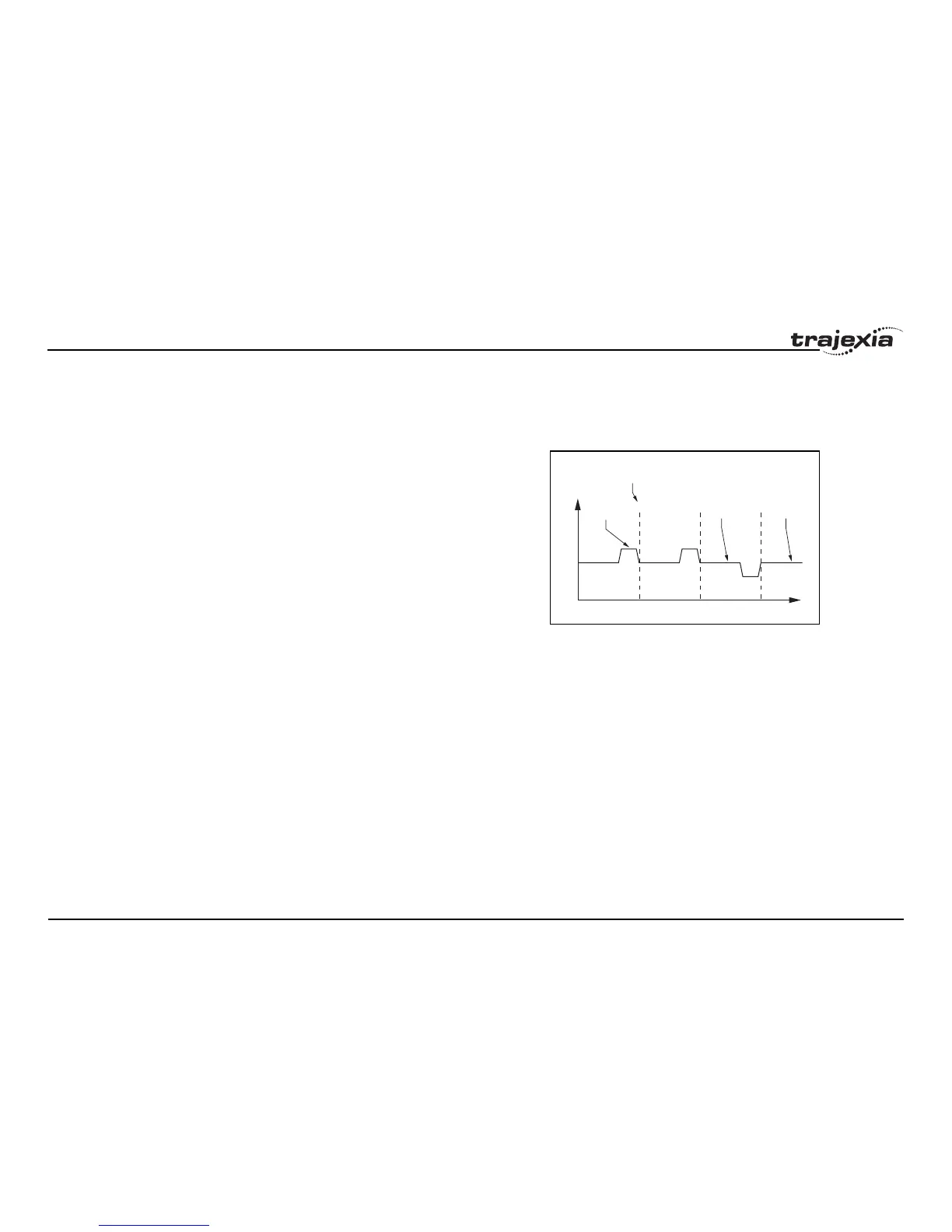

The difference between the expected position and the actual position is

measured with a photocell. This is the correction factor.

Every time a correction is made, the origin position is updated accordingly.

Example

fig. 59

conveyor=0

labeller=1

virtual=15

SERVO AXIS(conveyor)=1

SERVO AXIS(labeller)=1

WDOG=1

BASE(labeller)

CONNECT(1,conveyor)

ADDAX(virtual)

FORWARD AXIS(conveyor)

REGIST(1)

WAIT UNTIL MARK=0

loop:

WAIT UNTIL MARK

correction=REG_POS+expected_pos

MOVE(correction) AXIS(virtual)

WAIT IDLE AXIS(virtual)

OFFPOS=-label_length+correction

REGIST(1)

WAIT UNTIL MARK=0

GOTO loop

t

speed

0

0

0

OFFPOS

correction

labeller

conveyor

Loading...

Loading...