6-5SectionMaintenance and Inspections

99

6-4 Dealing with Abnormalities

The following three items are usual causes of problems in the ID Controller.

• Noise. Take countermeasures to deal with noise.

• Breakdowns in external equipment, in which case repairs are required.

• ID Controller breakdown, in which case repairs are required.

6-4-1 Noise

When

system mis-operation occurs due to noise, refer to the following table

to

take appropriate countermeasures to eliminate the influence of noise.

No. Problem conditions Probable cause Action

1 Occurs with large capacity

motor, transformers, or

capacitors when power is

applied.

Instantaneous

voltage drop in

power supply

system due to

large-scale load

surge current

There exists an abnormality in communications between

R/W Heads and DCs. Check communications speed,

distance, and obstacles.

Common mode

noise due to above

cause

Supply power via a 1:1 non-grounded insulated transformer.

Avoid common grounds with other large-scale loads, and

ground the ID Controller independently.

2 Occurs irregularly Noise on power

lines

Supply power via a 1:1 non-grounded insulated transformer

or a noise filter.

3 Mis-operation such as

turning input signal on

when it is off

Induced noise in

input wiring

Lay input signal grounds away from other power lines.

If noise effects are large, insert inside metal line pipes or

use shielded cables.

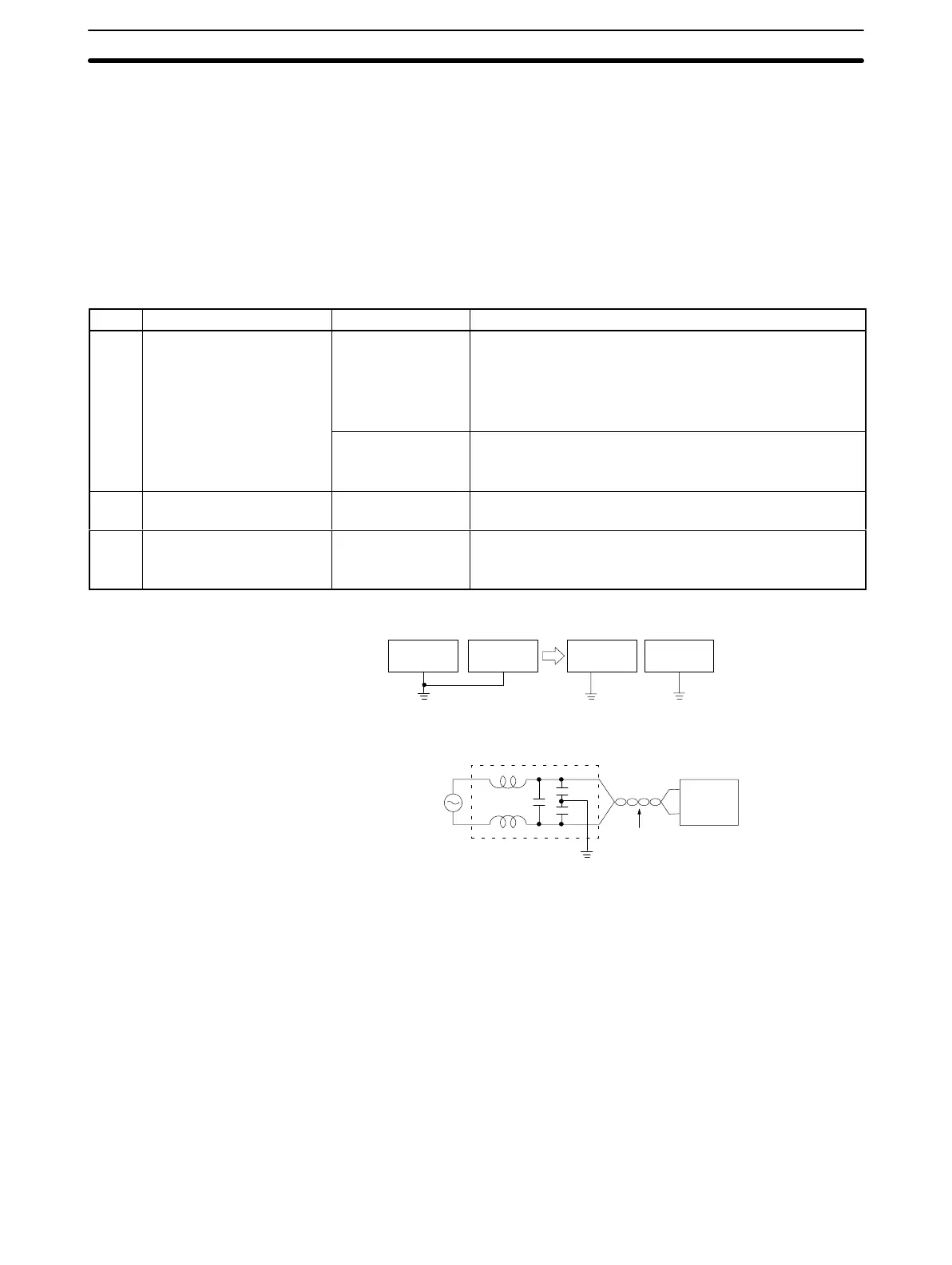

Improving Ground

Other

equipment

ID

Controller

GR,

Class 3 ground

Other

equipment

ID

controller

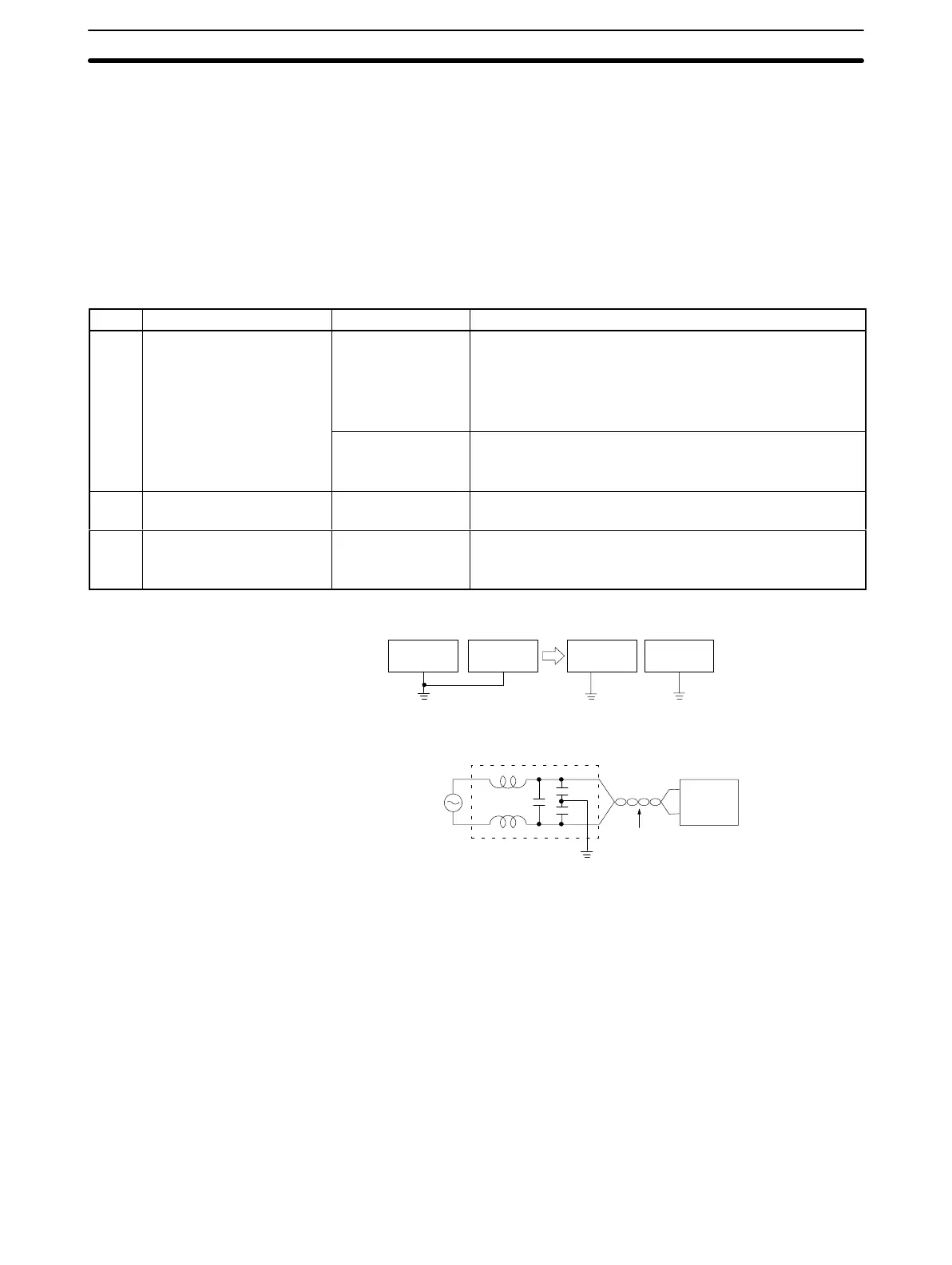

Dealing with Power Supply Noise

Power

supply

Noise

filter

ID

Controller

T

wist lines and ensure that

they are not parallel to other

power lines

6-5 Maintenance and Inspections

Daily

and other regular

inspections are required to keep the ID Controller func

-

tions

operating at optimal levels. The ID Controller main sections are configured

from

IC components, and consequently there are almost no consumable items,

but

the following problems may occur due to environmental or operating condi

-

tions.

• Excessive voltage or excessive current causing element deterioration.

• Use

in high ambient temperature locations can cause long term stress leading

to the deterioration of elements.

• Deterioration

of

insulation due to humidity

, dust, or deterioration in connector

connections.

• Corrosive gas causing bad connector connections or corroding elements.

Loading...

Loading...