5-3SectionWiring Procedures

80

5-3 Wiring Procedures

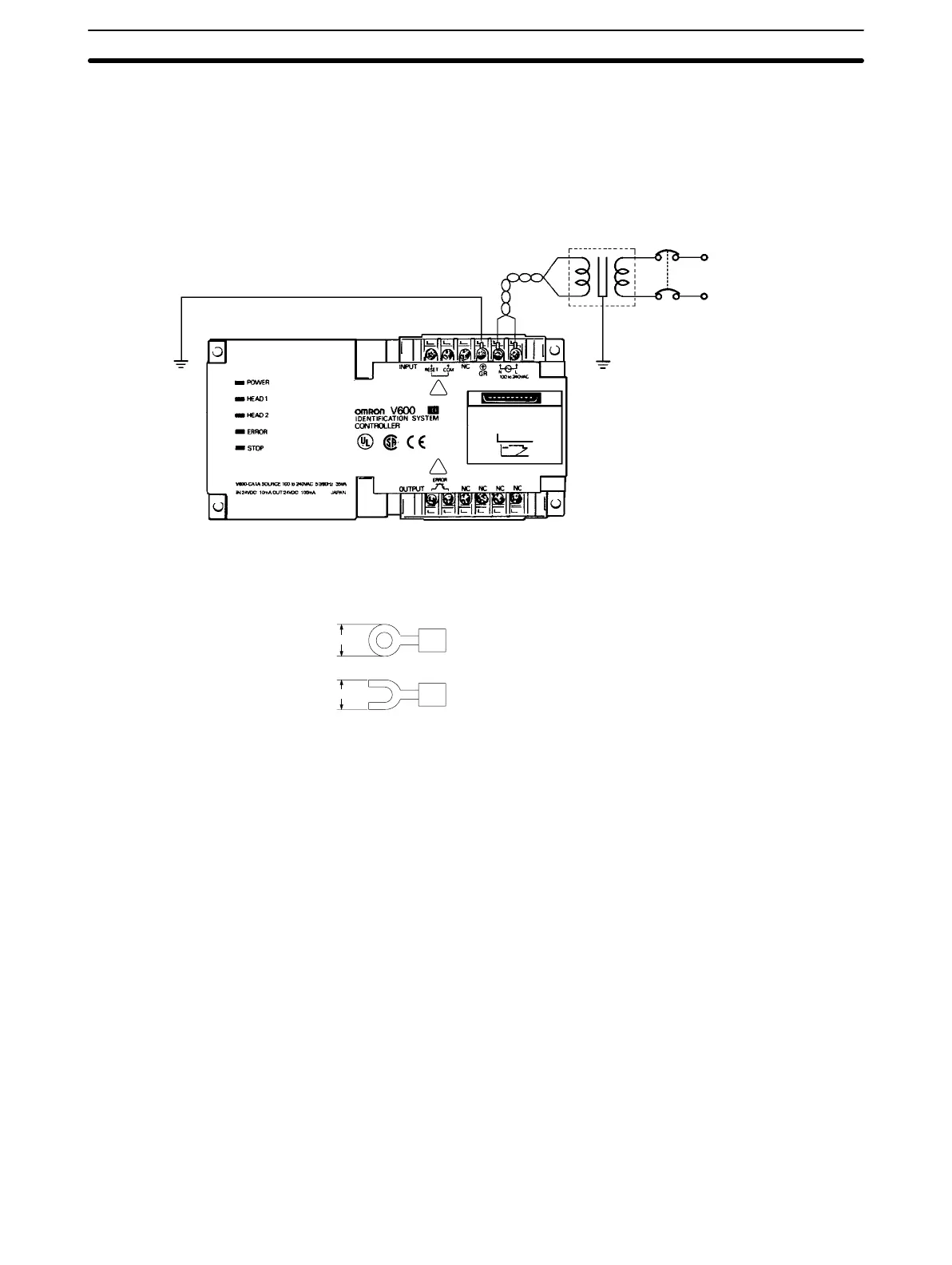

5-3-1 Power Supply and Ground Line Wiring

The ID Controller conforms to IEC1010-1, EN61010-1, UL3101, and

CSA1010-1. Therefore, field wiring is readily available.

Class

3

ground

Breaker

Insulated transformer

AC power supply:

100 to 240 V

AC,

50/60 Hz

!

!

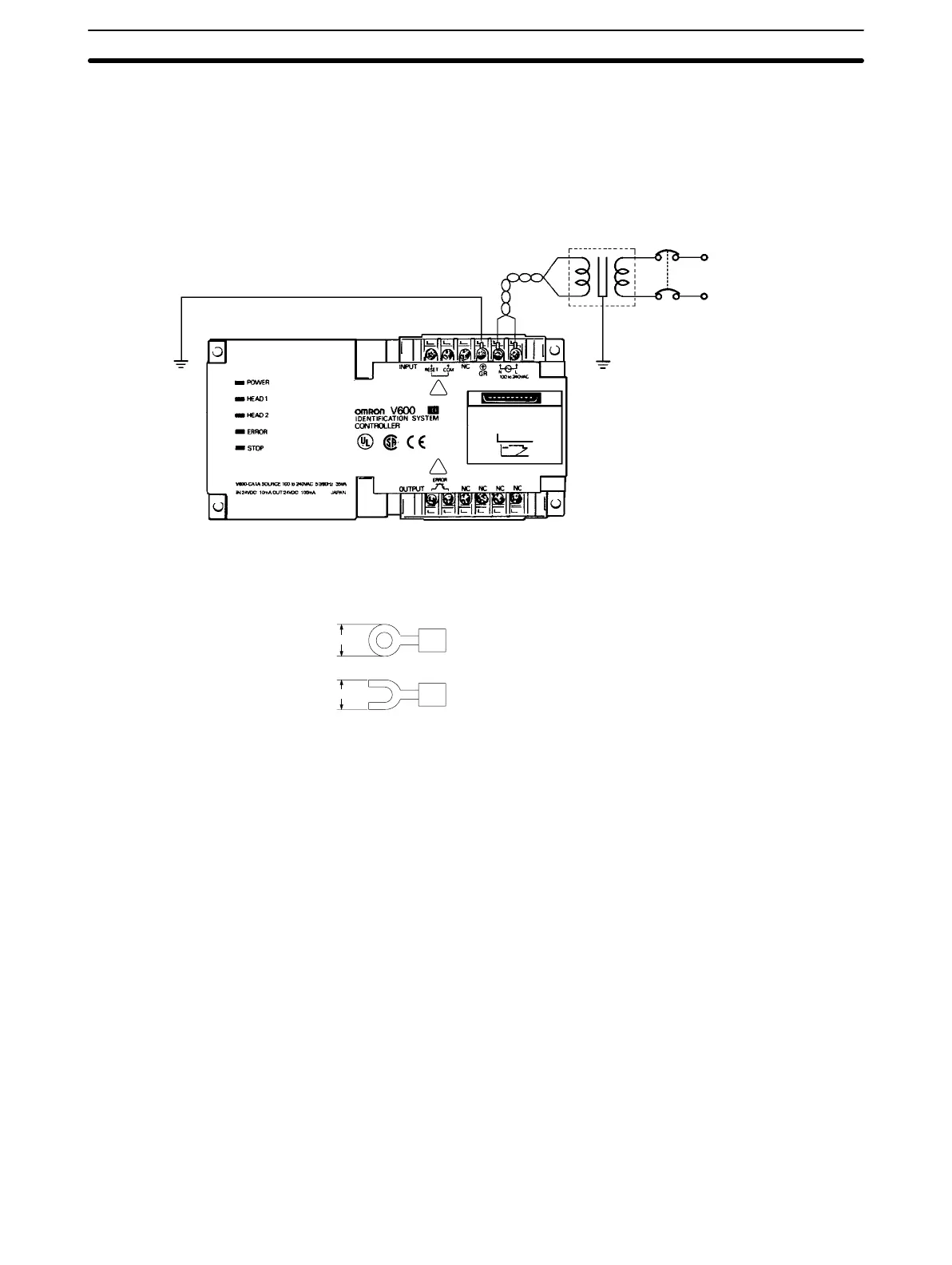

• The screws used on the power supply and the protective conductor terminal

are

M3.5 self-tapping screws. If a crimp-on terminal is to be used, select one

from those shown below. Ensure that the binding torque is about 8 kg • cm.

7.0

max.

7.0 max.

(for M3.5 screws)

• Ensure that the line voltage is in the range of 100 to 240 VAC. It is also

extremely

important to ensure that the permissible voltage variation range of

85 to 264 VAC is not exceeded.

• The

ID Controller has internal components to deal with noise

from the power

line,

and supplying power

via a 1:1 insulated transformer drastically attenuates

ground noise.

• The

ID Controller power consumption is less than 35 V

A using the maximum

configuration,

but when setting up the power supply

, note that there is a surge

current

of approximately 15 A (at 100 V

AC)

when power is applied to the sys

-

tem.

• Use

a power cable with at least a 2-mm

2

cross-section with no voltage drop. It

is recommended that the power wires be twisted for use.

• To prevent electric shocks and improve noise resistance, independently

ground the ID Controller at a resistance of less than 100 Ω.

• Do not use the open terminal (NC terminal).

5-3-2 Input/Output Line Wiring Precautions

Reset Signal Input

• Take

suf

ficient care to ensure that the input voltage does not exceed the maxi

-

mum applied voltage (26.4 V). Exceeding the permissible voltage level will

damage the equipment.

Loading...

Loading...