1-3SectionOperation

5

1-3 Operation

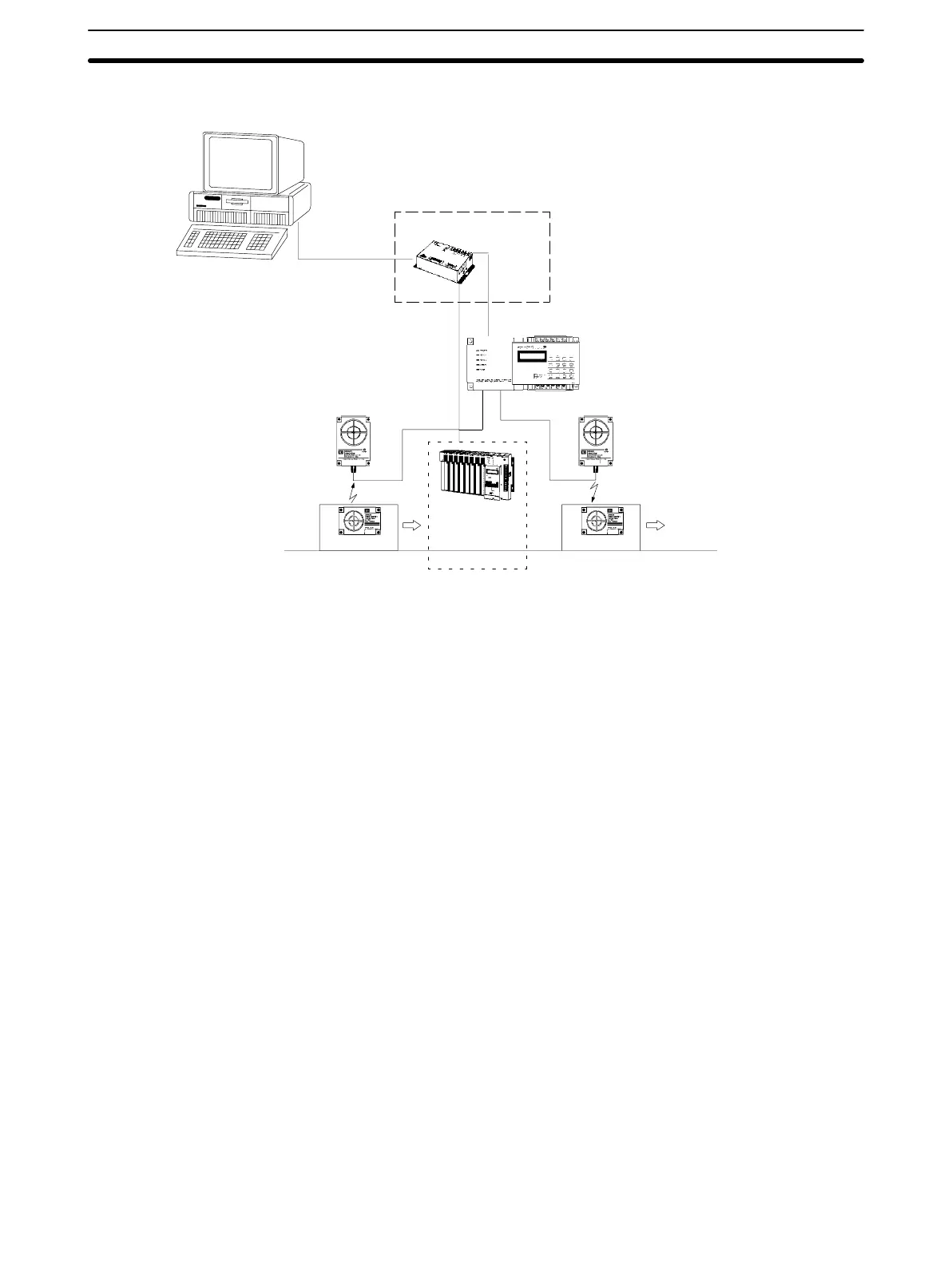

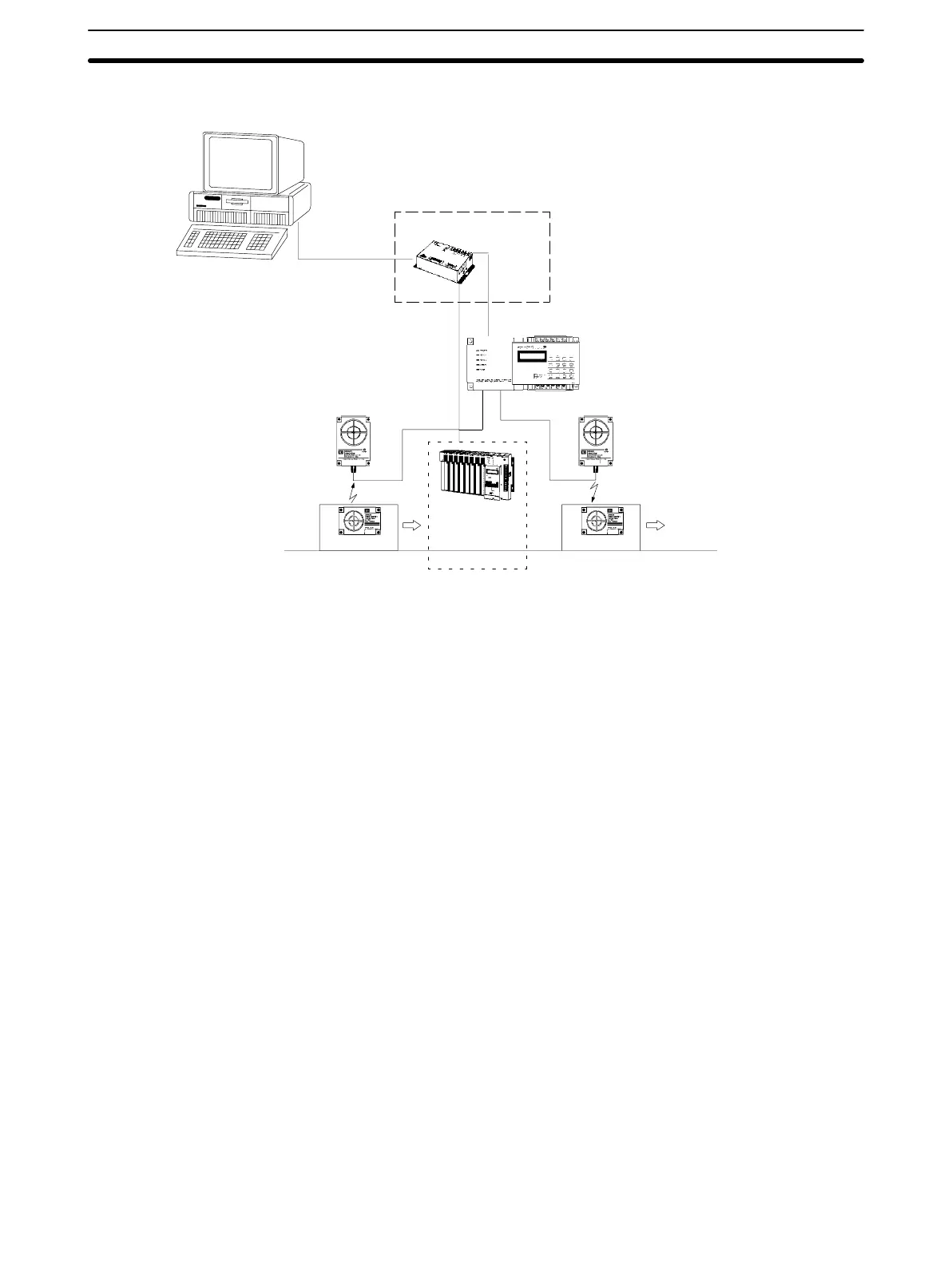

Link

Adaptor*

Machining/inspection

(Machining command data read)

To next process

R/W Head 2

ID Controller

(V600-CA2A-Vj)

RS-422

RS-232C

Host computer

Programmable

Controller

(PC)

R/W Head 1

PalletPallet

(W

rite inspection results data)

*When using a V600-CA2A-V

j

ID Controller

,

Link Adaptors must be used.

(IBM PC/A

T or compatible)

1, 2, 3...

1. When

a command is sent from the host computer to the ID Controller

, R/W

Head 1 enters the waiting condition and waits for the arrival of

the DC. The

command

data at this time specifies the memory area from which data is to

be read by R/W Head 1.

2. When

the DC arrives within communications range of R/W Head 1, the data

(format

and machining/inspection command data)

in the memory area indi

-

cated

by the read command is sent to the host computer as the response.

3. Based on the response data, the host computer transmits the workpiece

machining/inspection command to the PC.

4. Once operations in the machining/inspection process have been com-

pleted, machining/inspection results data is sent from the PC to the IBM

PC/AT or compatible.

5. The host computer sends a write command to the ID Controller, and this

time

R/W Head 2 waits for arrival of

the DC. This command sets the memory

area

to which R/W Head 2 is to write data and set the machining/inspection

results data.

6. When

the

DC arrives in the R/W Head 2 communications range, the machin

-

ing/inspection results data is written to the memory area specified by the

DC.

Loading...

Loading...