34

If you use an industrial water chiller instead of the provided pump, follow its separate instructions for maintenance

but similarly ensure that the water used remains cool, clean, and pure.

5.3.2 Cleaning the Main Bay and Engraver

Check at least once a day whether dust has accumulated in the main engraving bay. If so, it must be removed. The

exact cleaning interval and requirements strongly depend on the material being processed and the operating time of

the device. A clean machine guarantees optimal performance and reduces service costs, as well as reducing the risk

of fi re or injury.

Clean the viewing window with mild cleansers and a lens or cotton cloth. DO NOT use paper towels as they can

scratch the window and reduce the cover's ability to protect you from laser radiation. Clean the interior of the main

bay thoroughly, removing any debris particles or deposits. Paper towels and window cleaner are recommended.

When necessary, clean the cover of the laser tube after it has been allowed to cool completely. Allow any fl uid used

in any cleaning to dry completely before further use of the engraver.

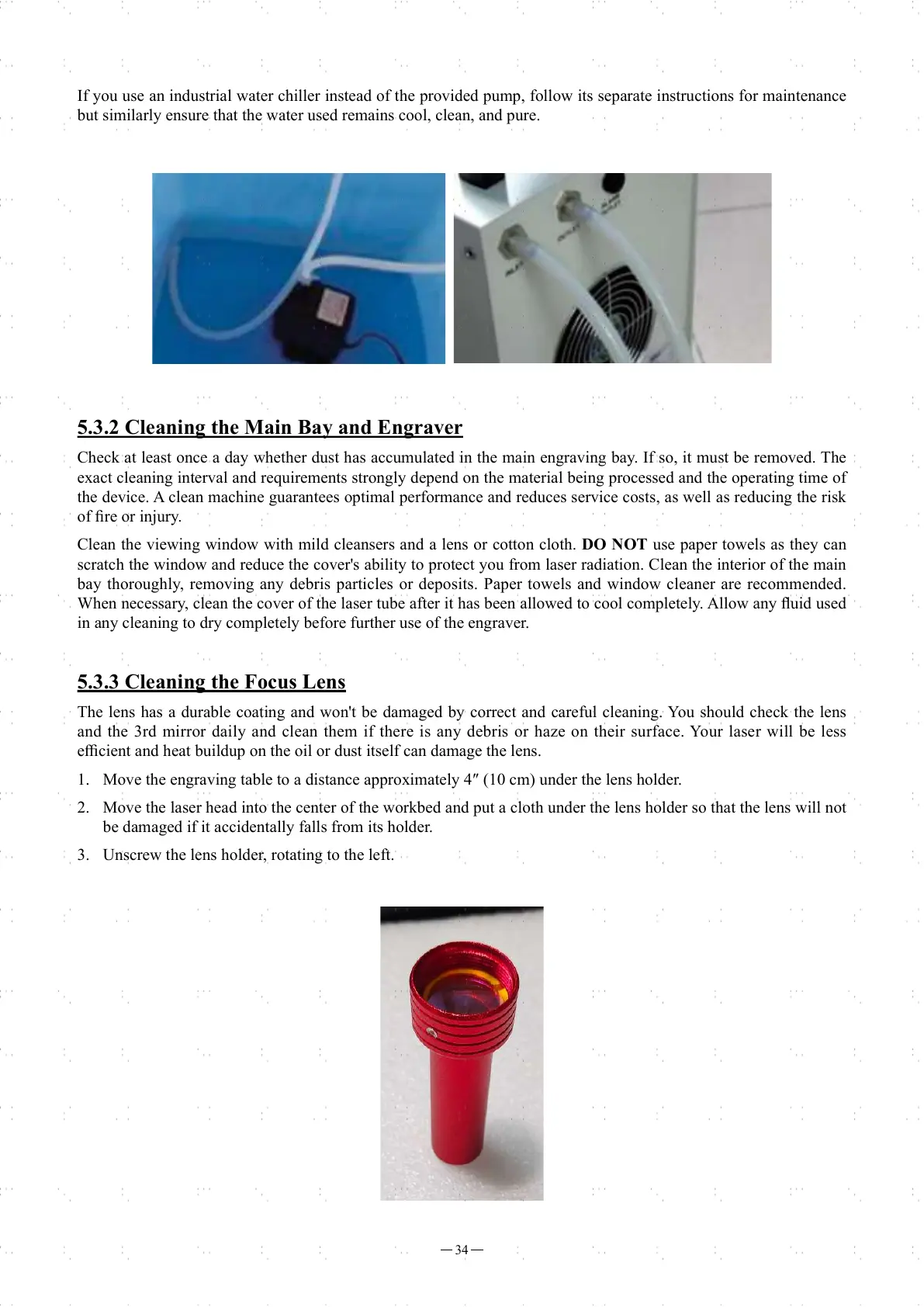

5.3.3 Cleaning the Focus Lens

The lens has a durable coating and won't be damaged by correct and careful cleaning. You should check the lens

and the 3rd mirror daily and clean them if there is any debris or haze on their surface. Your laser will be less

effi cient and heat buildup on the oil or dust itself can damage the lens.

1. Move the engraving table to a distance approximately 4″ (10 cm) under the lens holder.

2. Move the laser head into the center of the workbed and put a cloth under the lens holder so that the lens will not

be damaged if it accidentally falls from its holder.

3. Unscrew the lens holder, rotating to the left.

Loading...

Loading...