20º

Oneida Air Systems, Inc.26

Filter Pulse Bar Cleaning

e Pulse Filter System helps to unclog the lter for improved

airow and performance. If air ow is not restored aer pulsing,

check for clogs and clean lter. (Review Cleaning the Filter and

Troubleshooting Sections).

1. Pulse your lter regularly—including multiple times per day

when collecting ne dust—or when you notice decreased

airow. Frequent pulse cleaning of the lter will keep your

performance optimal.

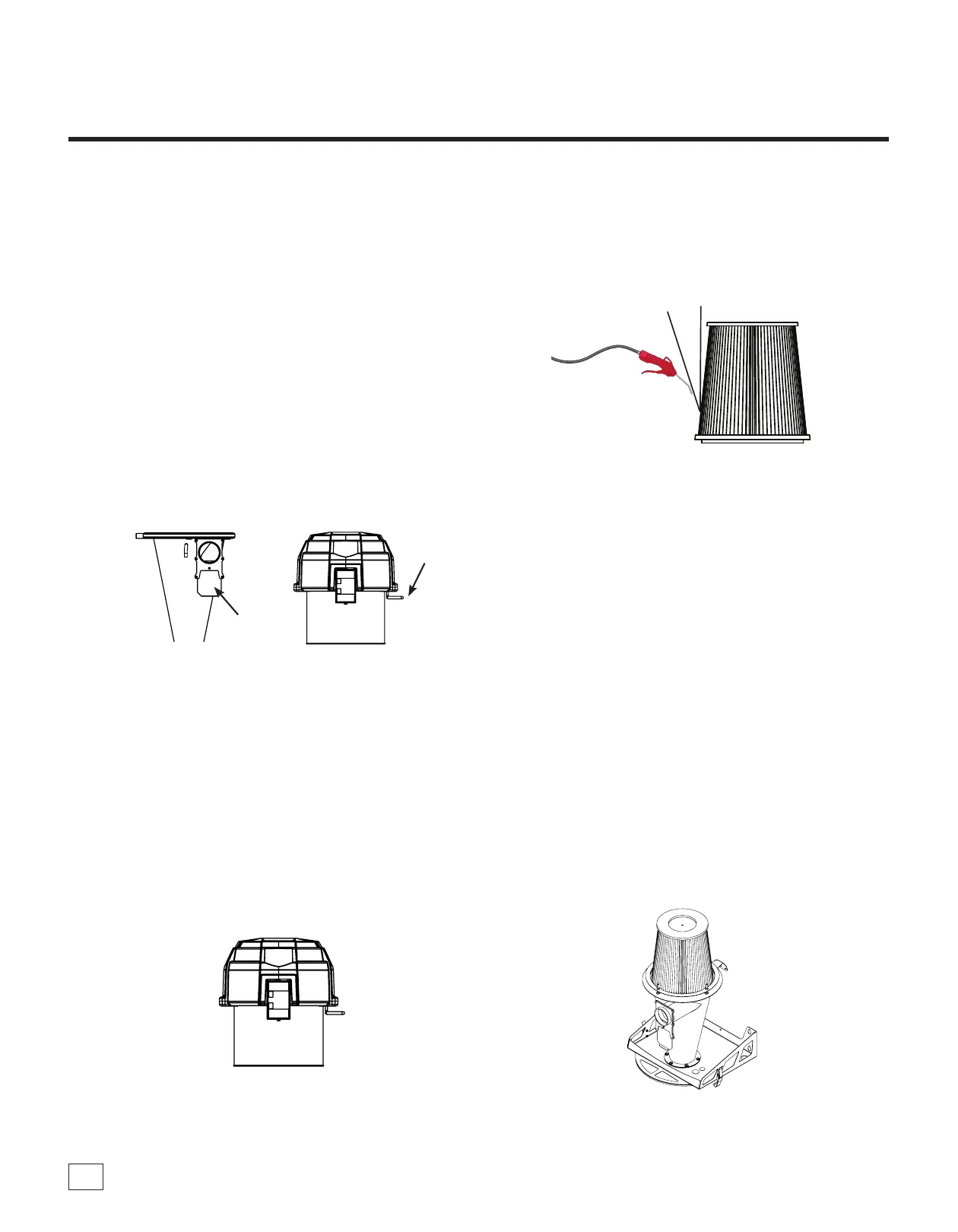

2. While the unit is running, close the Blast Gate on the inlet

of the Cyclone. Once closed, push down the Pulse Bar

extending out of the cowling, past the initial resistance, and

hold for a few seconds then release the Pulse Bar. Repeat ve

times.

3. Open Blast Gate to resume normal operation.

Cleaning the Filter

We recommend pulsing the Filter regularly – at minimum

before you start to work and when you are nished for the day. If

performance has decreased and pulsing does not restore airow,

the Filter should be replaced.

1. Wear a dust mask and eye protection.

2. Turn o and unplug the dust collector and wait for the fan

blower to come to a complete stop and for the dust to settle.

3. Unlatch the Ring Clamp (D) at the base of the motor section

and allow it to hang freely. Remove the motor section and

set aside.

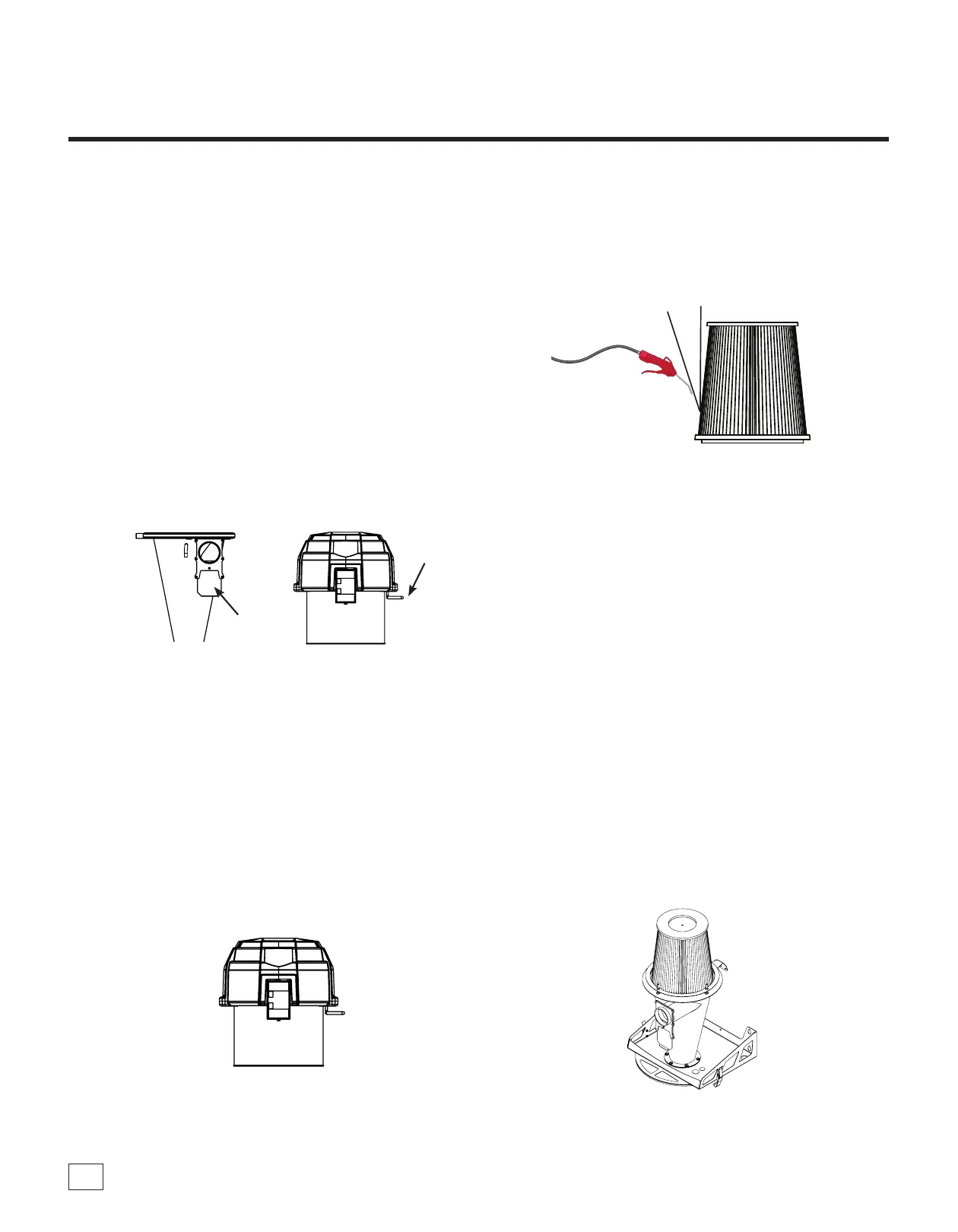

4. Use a hand-held, compressed air nozzle with a pressure up

to 90 PSI max to blast air along the lter’s exterior pleating.

Hold the air nozzle at a 20 degree angle and at least 2" away

from the lter; closer blasts will damage the lter material.

Direct air out and away from anyone in the area. Do not

use this method when any hazardous material has been

vacuumed up.

5. Check to make sure lter is in good condition with no

torn media or cracks or tears in the seal. A broken lter

can leak material into the motor and cause severe damage!

You cannot operate the system without a proper lter in

place. (See Accessories page for the replacement lter part.)

Operating without a sucient lter will cause severe damage

to the motor and will void the warranty!

Note: To help see damage from the outside, shine a ashlight

from the inside. If the lter is removed aer it's been in service

for some time, the gasket may no longer return to it's original

thickness. In this case, ensure enough gasket thickness remains

for proper sealing to prevent dust from escaping.

6. If the lter isn't in good condition, remove the Filter (C) by

removing the four 5/16-18 Nylock Nuts (G11) and the Filter

Hold-Down Ring (B) by sliding it over the lter. Dispose of

the old lter in the same way you would dispose of the dust

you’ve been collecting.

7. Center new Filter (C) over the center of the Cyclone (E)

and place the Filter Hold-Down Ring (B) over the Filter (C)

and re-secure using the four 5/16-18 Nylock Nuts (G11.)

Tighten hardware so that the Filter's pre-installed foam

gasket is rmly compressed (by roughly 50%). DO NOT

OVERTIGHTEN.

8. Replace the motor section and re-latch the drum clamp

around the motor section.

Maintenance

UNPLUG YOUR UNIT BEFORE SERVICING OR CLEANING. KEEP THE TOP VENTS IN THE COWLING CLEAN.

THESE ARE FOR BOTH EXHAUST AND INCOMING COOLING AIR FOR THE MOTOR.

Pulse Bar

Blast

Gate

Loading...

Loading...