OPTIMUM

MASCHINEN - GERMANY

Maintenance

Version 2.0.2 2014-11-04Page 44 Original operating instructions

B17Pro | B23Pro | B26Pro | B33ProGB

6.2 Inspection and maintenance

The type and level of wear depends to a large extent on the individual usage and operating

conditions.

Interval Where? What? How?

Start of shift

after every

maintenance

or repair work

Drilling machine

"Safety check“ on page 15

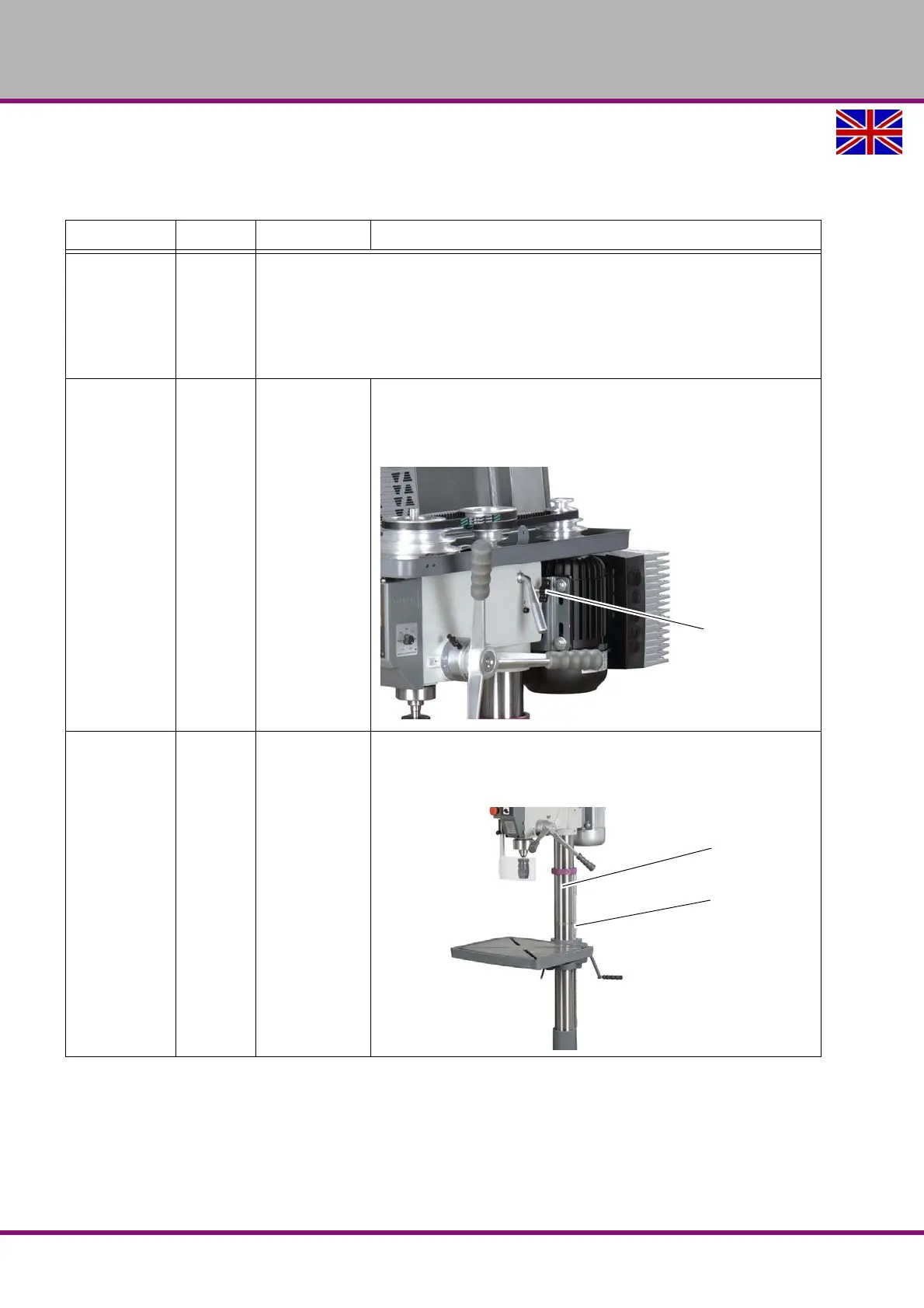

every week

Slide rail screws

Loosening

Check if the slide rail screws for the V-belt tension on the

left and right side of the drilling head are well fastened.

Check if the V-belts are well tightened. Checking the ten-

sion of V-belts,

"Speed change“ on page 33.

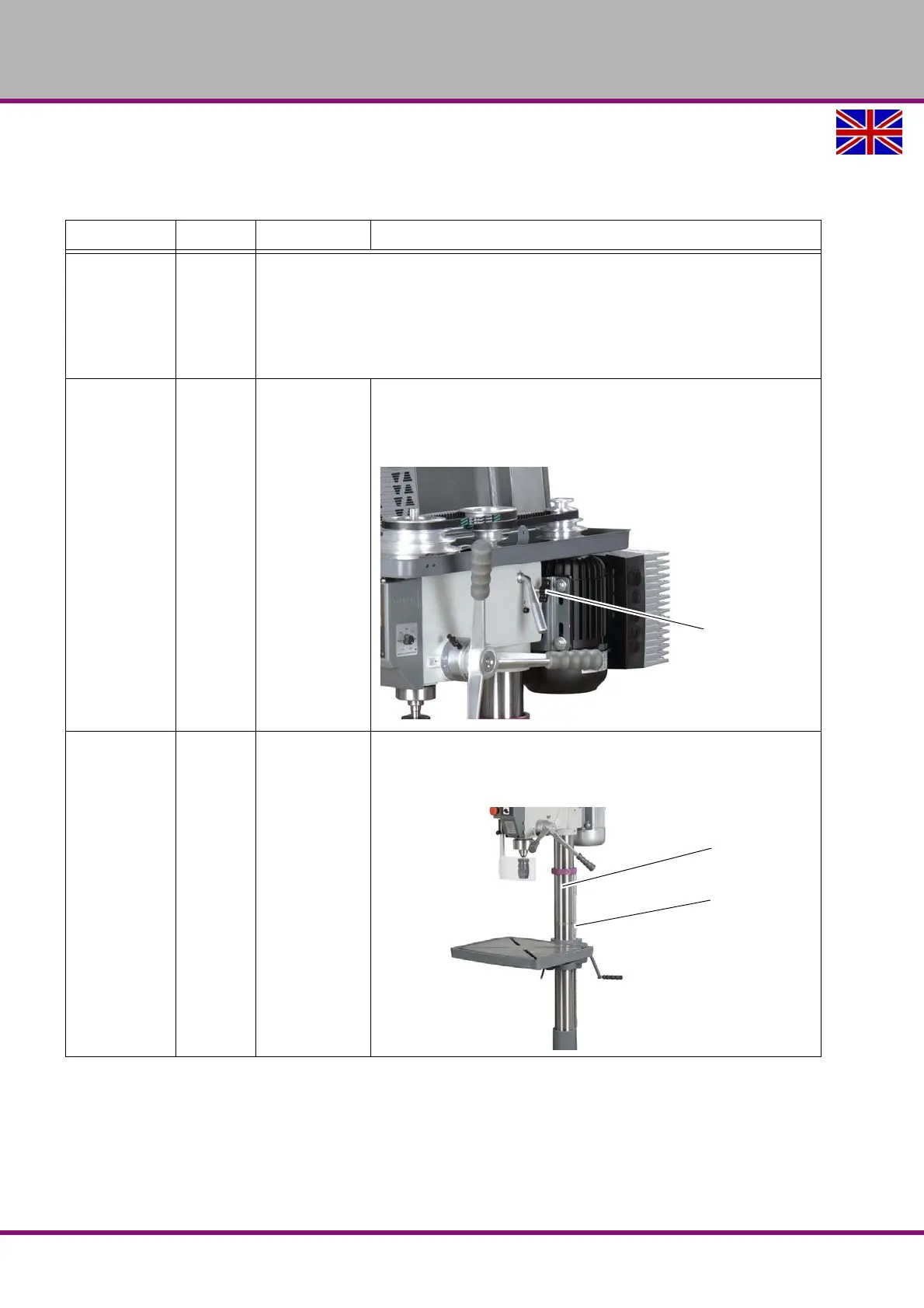

Every month

Rack and upright drill

lubricate

Lubricate the drill column regularly with commercial oil.

Lubricate the rack regularly with commercial grease (e.g.

friction bearing grease).

Slide rail screws

right-hand side

Drilling column

Toothed rack

Loading...

Loading...