OPTIMUM

MASCHINEN - GERMANY

Malfunctions

Version 2.0.2 2014-11-04 Page 73Original operating instructions

B17Pro | B23Pro | B26Pro | B33Pro GB

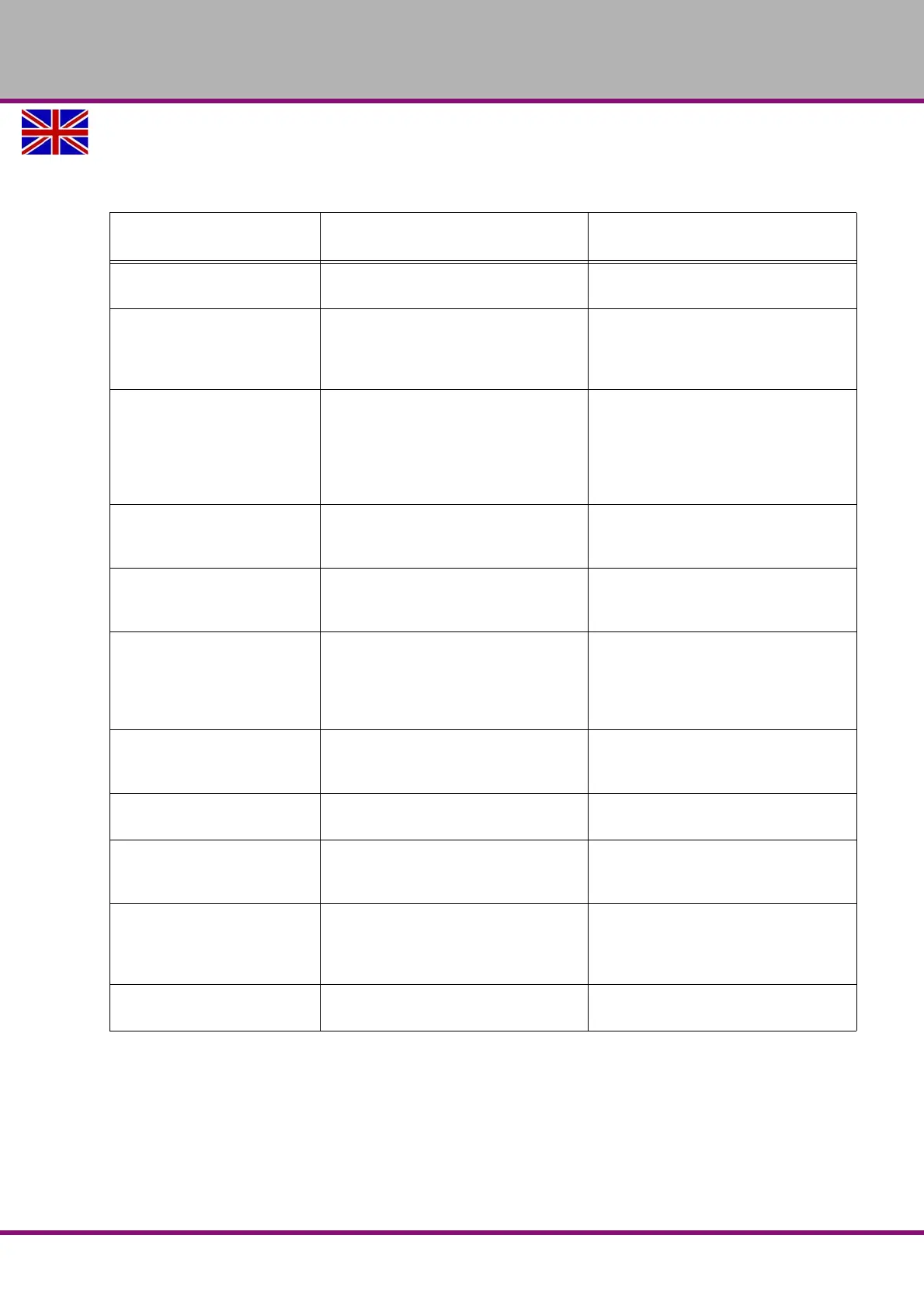

8 Malfunctions

8.1 Malfunctions on the drilling machine

Malfunction

Cause/

possible effects

Solution

Release of the FI protected

switch

• an unusual

FI protective switch is being used

• "Power supply“ on page 29

Noise during work. • Spindle turning dry

• Tool blunt or incorrectly secured

• Grease spindle

• Use new tool and check securing

(fixed setting of the bit, bit holder and

chuck).

Drill bit "burnt“ • Incorrect speed

• The filings have not been removed

from the bore hole

• Blunt drill bit.

• Operating without cooling agent

• Select another rate, feed too high

• Retract the drill bit from the bore hole

more often.

• Sharpen the drill bit or insert new drill

bit.

• Use cooling agent

Drill point runs off, drilled hole

is not circular.

• Hard fibre in wood or length of the

cutting twist or the drill bit is uneven.

• Drill bit is bent.

• Use a new drill bit.

Drill bit defective. • No base / support used. • Place a piece of wood underneath

the workpiece and fasten this to the

workpiece.

Drill bit runs unround or wob-

bles.

• Drill bit is bent.

• Worn bearing on boring head.

• Drill is not correctly clamped.

• Drill chuck defective

• Replace drill bit

• Have the bearing on the boring head

replaced.

• Set the correct tension to the drill bit.

• Exchange the drill chuck.

The drill chuck or the taper

mandril cannot be inserted.

• Dirt, grease or oil on the taper inside

of the drill chuck or on the taper sur-

face of the drill spindle

• Clean the surfaces accurately

• Keep surfaces free of grease

Motor does not start • Motor is wrongly connected

• Defective fuse

• Have it checked by authorised per-

sonnel.

Motor is overheating and there

is no power

• Motor overloaded

• Too low mains voltage

• Motor is wrongly connected

• Disconnect immediately and have

the equipment checked by a trained

specialist

Precision of the work deficient • Heavy and unbalanced or deformed

part

• Inexact horizontal position of the part

holder

• Balance the piece statically and

secure without straining

• Adjust part-holder

Drilling spindle sleeve does not

return to its initial position

• Spindle return spring • “Spindle return spring“ on page 45

Loading...

Loading...