15

OrionWelders.com

ch.1

6. Lock the electrode into place by hand tightening the collet cap

in a clockwise direction.

7. Replace the stylus hull by pushing it snuggly until you feel it

snap back into place (the electrode should stick out between 1/8 –

1/4in (3.75 – 6.75mm) after the stylus hull is snapped back into place).

WORK PIECE TO ELECTRODE PRESSURE

A video explanation of the instruction below can be found at http://www.orionwelders.com/

resources/orion-c-series-resources/

Touch the work piece to the electrode with very light pressure. Too much pressure will cause

the work piece to stick to the electrode and in turn cause the electrode to be contaminated

(work piece material on the electrode). is will shorten the amount of time you can weld before

re-sharpening or replacing the electrode. *As a general rule of thumb we recommend a freshly

sharpened electrode anytime a new work piece is being welded.

WHEN TO SHARPEN THE ELECTRODE

It is recommended that the user pay close attention to the electrode condition. An electrode that

appears to be dark colored or covered with material from previous welds can lead to inconsistent

welding and poor igniting of the weld. When this occurs, simply sharpen the electrode with the

included diamond disk. e diamond disk can be attached to a flex shaft or Dremel tool. Follow

these steps for sharpening the electrode. A video explanation of the steps below can be found at

http://www.orionwelders.com/resources/orion-c-series-resources/

1. Completely remove the electrode from the stylus.

2. Pinch the electrode between the thumb and middle finger with the point facing inward.

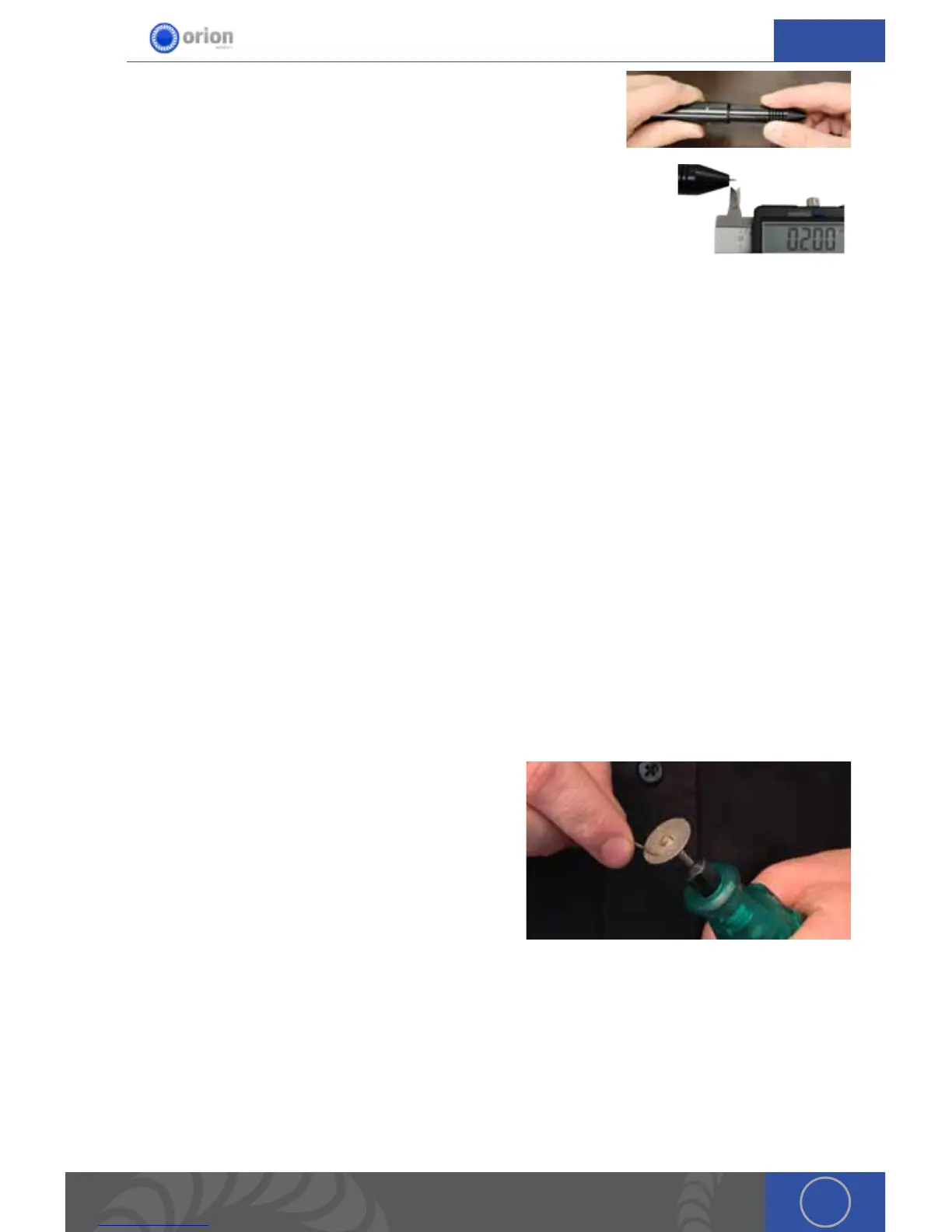

3. Power on the Dremel or flex shaft then hold it with

the opposite hand. *If the Dremel is in the left

hand, then sharpen the electrode on the side of the

diamond disk furthest from the body. If the Dremel

is in the right hand, then sharpen the electrode on

the side of the diamond disk closest to the body.

e reason for this is to keep the striations on the

electrode moving towards the electrode tip, not

away. is will effect the quality of the weld if not

done as explained above.

4. Set the electrode on the diamond disk at a 10-degree angle and begin to spin the electrode

with the thumb and middle finger. *A helpful way to get a sharp electrode is to push down on

the electrode with your index finger while twisting the electrode with the thumb and middle

finger. See the video on our website for additional instruction on this method.

5. Once the electrode is sharp and clean, turn the Dremel off and insert the electrode back into

the stylus as explained above.

*See Chapter 5 for additional information on the Tungsten Electrodes

Loading...

Loading...