100c User Manual

32

ch.5

CHAPTER 5: TUNGSTEN ELECTRODES

THE SINGLE MOST IMPORTANT VARIABLE IN THE WELDING PROCESS IS THE ELECTRODE. e

Orion welder comes standard with (5) 0.5mm and (5) 1.0mm electrodes. e 1.0mm electrodes

are a good all around electrode while the 0.5mm electrode is excellent for very small projects. e

larger 1mm electrode allows more energy to come out at one time. e smaller 0.5mm electrode

may be better for cases when less energy is desired.

HANDS ON: Make a weld using 15 Ws using a sharp 1.0mm electrode. Now make a weld using the

same settings using a sharp 0.5mm tip.

In the ‘HANDS ON’ examples above, more energy was transferred from the Orion into the piece

for the same setting using the 1mm electrode. For very small parts using the small electrode is

sufficient. is option reduces the peak weld current versus using the large electrode and can

also allow for a smaller weld spot. For larger parts use the 1mm electrode. e 1mm electrode is

used when needing additional weld current (more melting for same energy). e larger electrode

is recommended for metals such as silver, due to higher welding energy requirements of such

metals.

*Note: e 0.5mm small electrode will “burn” or oxidize at higher energy settings. As a general

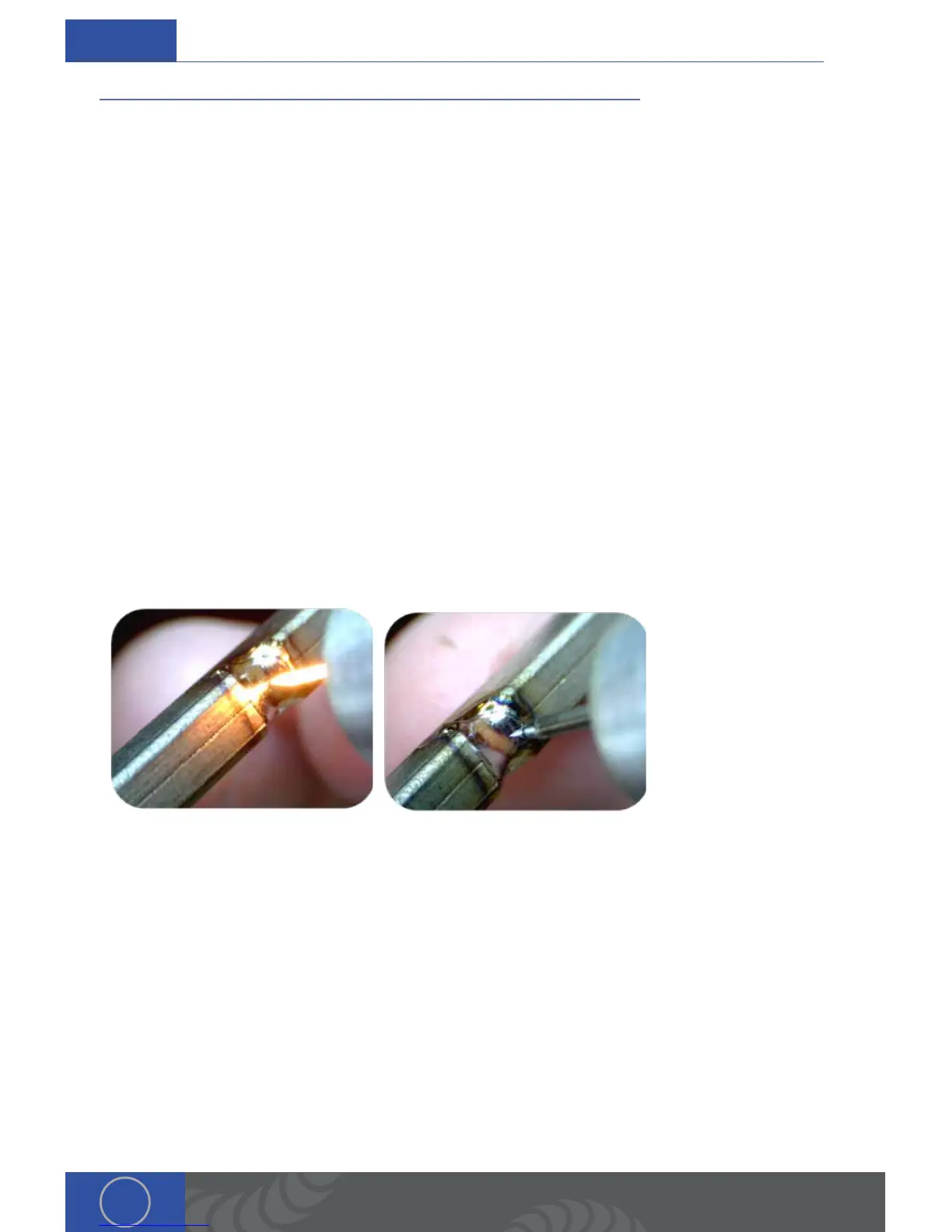

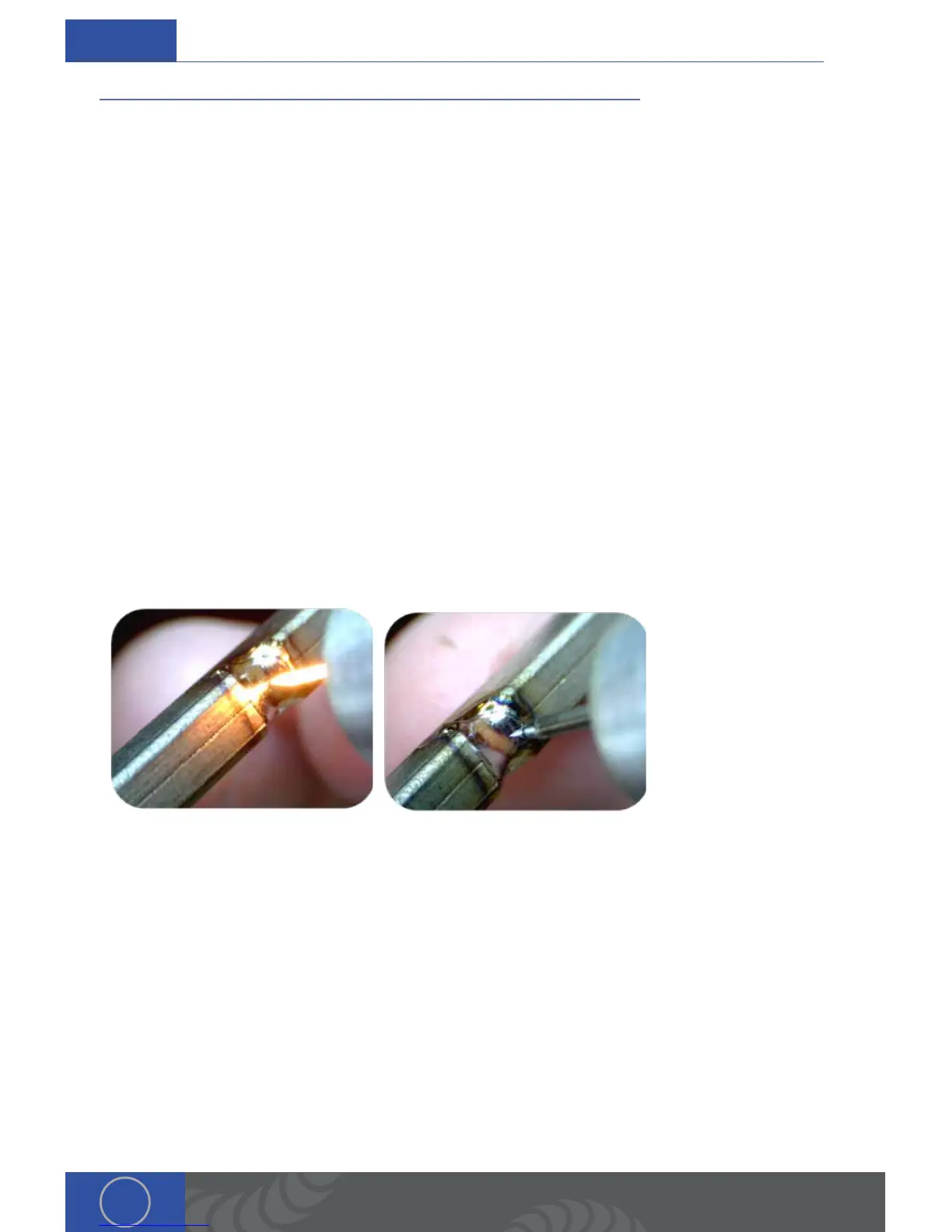

suggestion, the 1mm electrode is a good choice for most applications, even very small ones Left:

Using too much energy with the 0.5mm electrode will cause it to overheat and reduce its life.

Right: A 1.0mm electrode can weld at a variety of energies without overheating.

Why Use Tungsten Electrodes?

1. Hardness – tungsten is extremely hard and is therefore able to hold its shape during the

welding process.

2. Tungsten’s melting temperature is much higher than most other metals. is means the

metals being welded will melt before the tungsten.

Melting temperatures of selected metals:

e table shows a variety of metals and their corresponding melting temperatures. Note

that tungsten has a significantly higher melting temperature than the other metals. is is an

important attribute of tungsten that aids the welding process. While welding, electrons from the

weld plasma impact the work piece and form a weld spot. At the same time, positively charged

gas atoms impact the electrode. Both of these processes create heat. However, more heat is

Loading...

Loading...