33

OrionWelders.com

ch.5

generated by the electrons impacting

the work piece than the atoms striking

the electrode.

ELECTRODE SHAPE

e electrode shape is a very important aspect to consider and has a significant impact when

welding various metals. e shape of the electrode will greatly affect the welding plasma

created during the arc. Poor electrode shape will lead to plasma arcs that are not repeatable

while good electrode shape will help the plasma arc to discharge smoothly from the welding tip.

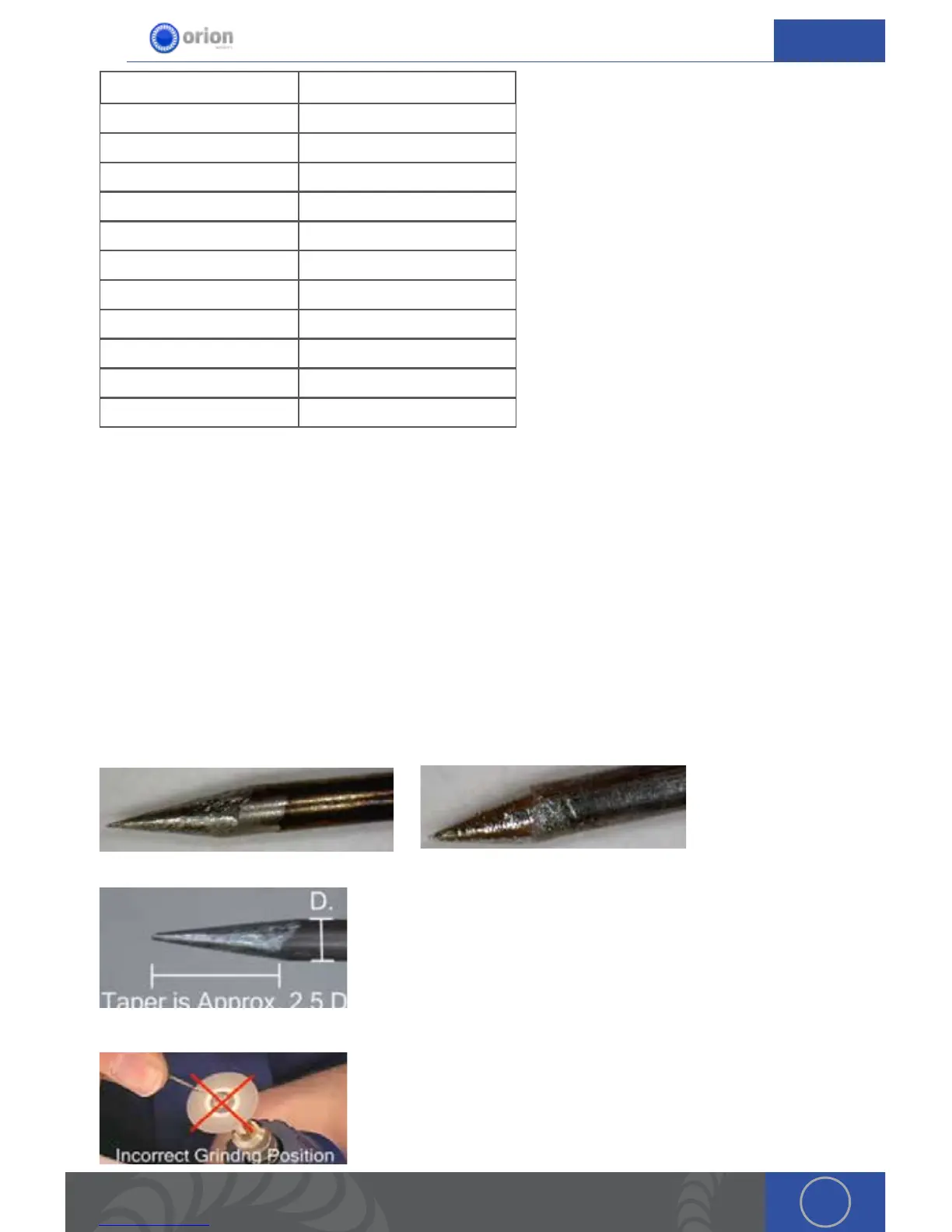

e grinding direction to sharpen the electrode is very important. When grinding, make sure

that grind marks run parallel to the electrode shaft. Parallel grind marks will allow the plasma to

discharge uniformly and smoothly from the electrode. Grinding the electrode such that circular

rings or marks show up will lead to a poor plasma arc, affecting weld quality. e plasma will

discharge inconsistently from the electrode ridges and may become unstable, oscillating in

time. e weld spot will not be repeatable.

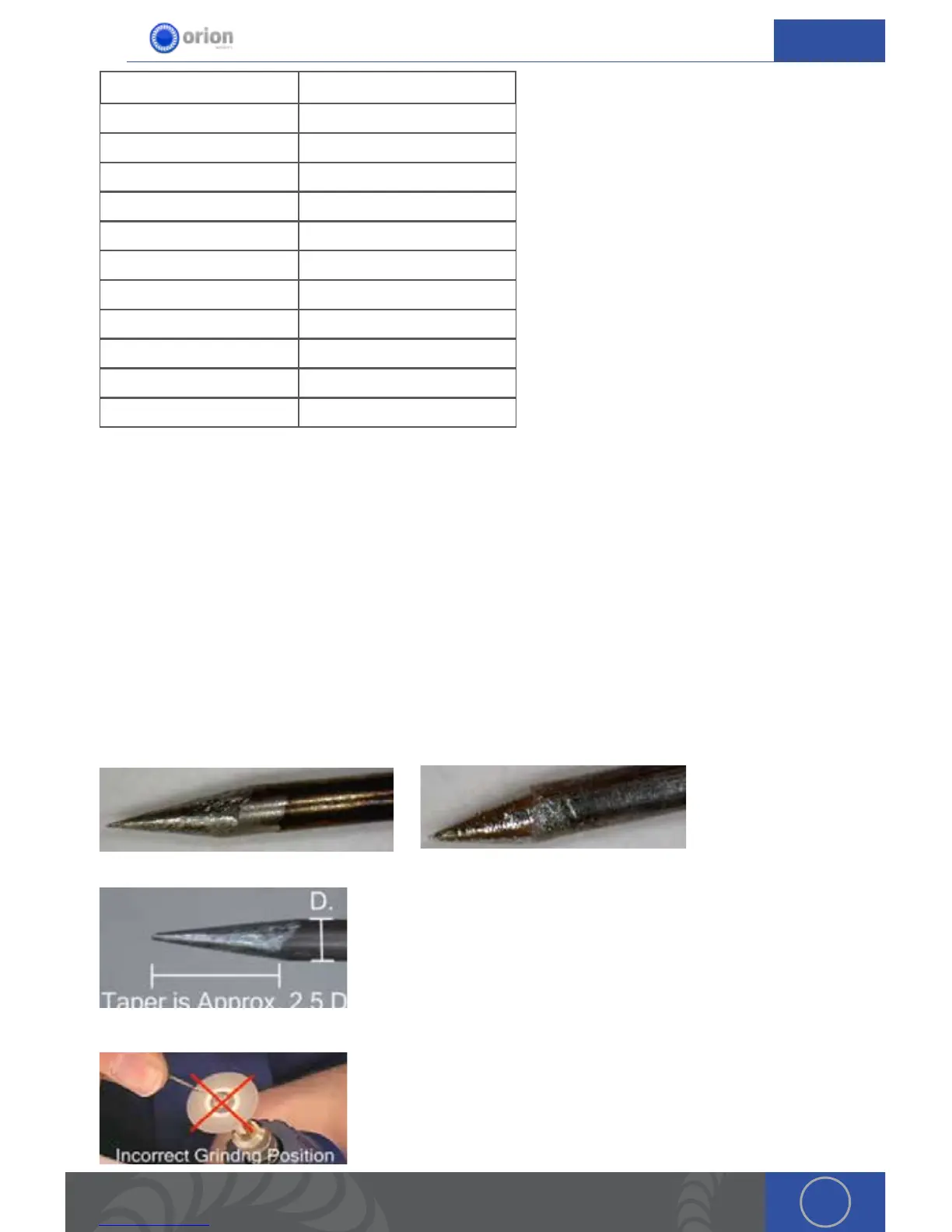

As a rule of thumb the electrode should be ground so that

the taper is approximately 2.5x the diameter. e resulting

electrode shape is a good general shape for easy arc ignition

and excellent weld spots.

Always grind the welding electrode so that grind marks

run parallel to the electrode shaft. Placing the electrode

incorrectly on the diamond wheel will produce circular grind

marks and poor weld results.

Good Bad

Material Melting Point (deg C)

Zinc 420

Aluminum 660

Silver 962

Gold 1064

Copper 1083

Stainless 304 1450

Carbon Steel 1500

Titanium 1660

Platinum 1772

Niobium 2468

Tungsten 3410

Loading...

Loading...