29

OrionWelders.com

ch.4

temperature (especially at the interface between the two pieces) can become hot enough to melt

the metal in a spot. e terms resistance welder and spot welder are descriptive of this process.

If you limit the amount of energy and electrical current going into the weld you can create a

temporary or weak weld called a “tack” weld. It provides the ability to temporarily position a part

before permanent welding. is ability opens a multitude of creative possibilities. It also helps

eliminate the need for complicated binding or clamping of parts before permanent welding or

soldering.

Because the heart of the Orion is an industrial capacitive resistance welder, everything from one

time custom pieces to production welding is possible.

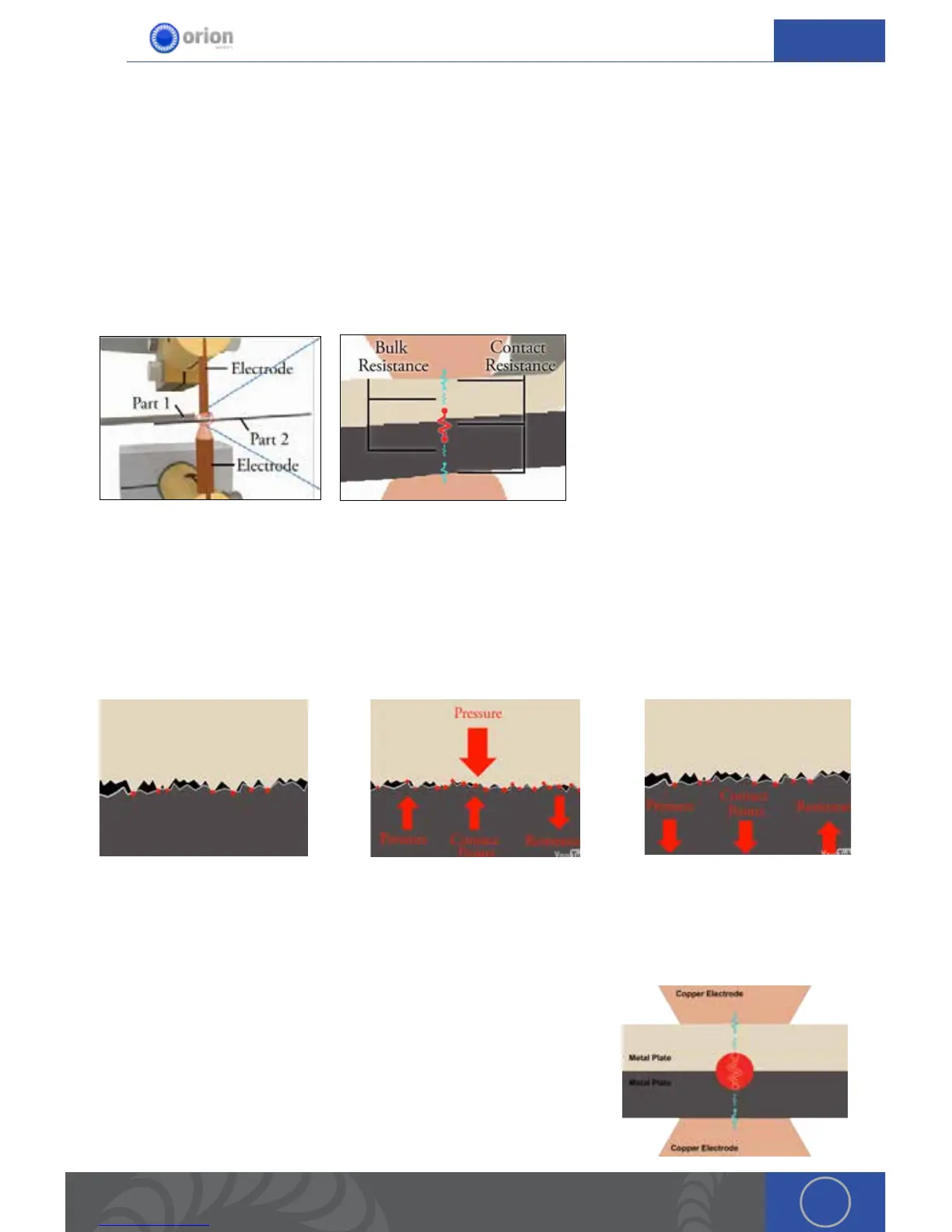

Left: A typical (industrial) welding

configuration. Right: A close-up

zoom of the weld showing the

electrical resistances that are

used to create the weld spot.

As shown in the figure above, a typical weld configuration requires a positive and negative

electrode with pressure applied to the work piece parts. As we zoom in on a cross sectional

view of the work piece parts, we can identify the electrical resistance locations where heat is

generated. For fine spot, or small scale resistance welding, most of the heat is generated at the

contact point between the two work pieces. is has been identified on the figure as the largest

resistance point. During the weld a large pulse of electrical current is dumped quickly through the

work piece causing rapid heating and melting at the electrode location.

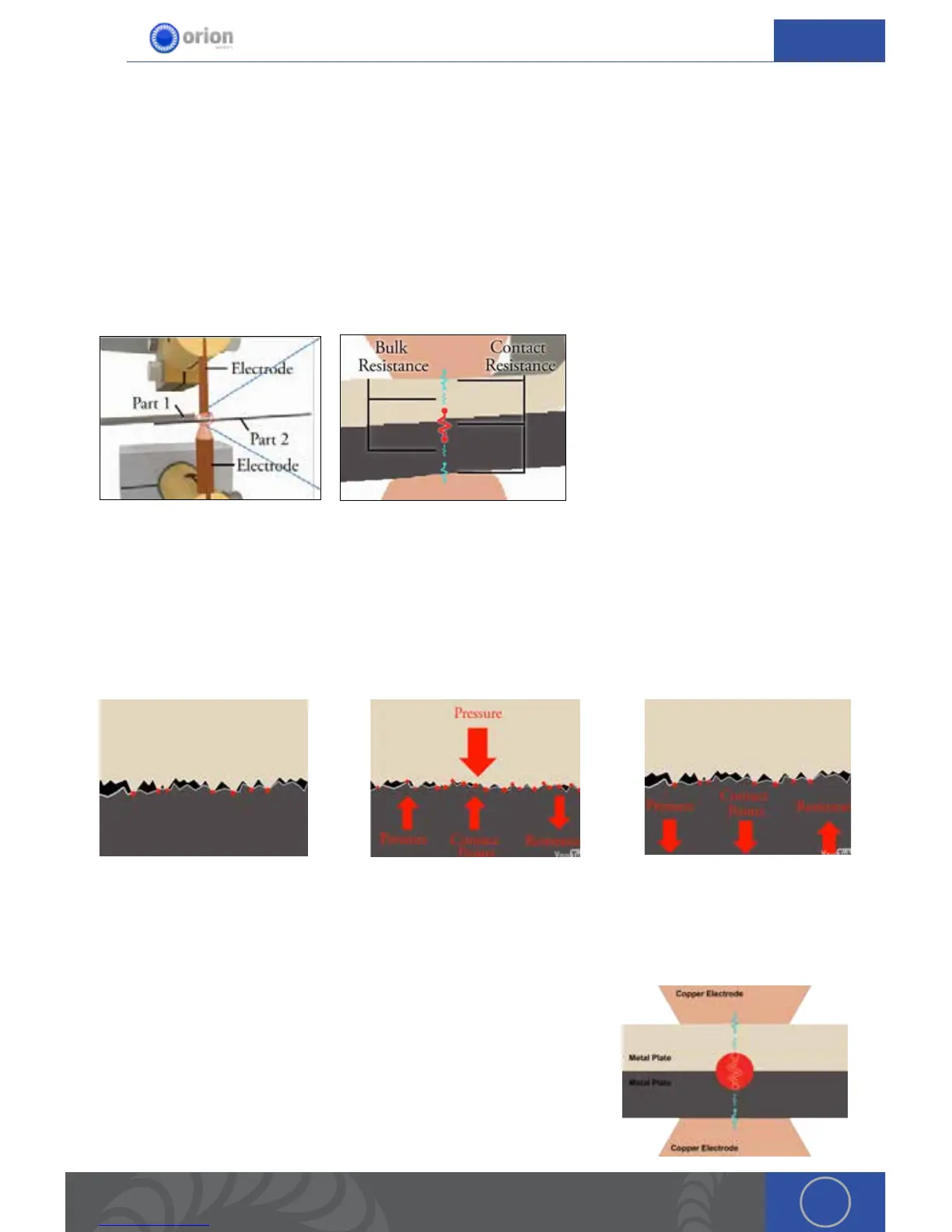

Left: On the micro scale all surfaces have a degree of surface roughness. is roughness causes

the work pieces to only contact in a limited number of locations. Middle: Applying more pressure

will cause more surface contact, less resistance and less resistive heating. Right: Applying less

pressure will cause less surface contact, more resistance for better resistive heating.

A resistance welder uses the resistance to the flow of electricity

to heat and melt the part via a large electrical current. is contact

point is where the highest heat is generated. Light pressure

between the parts means less contact between the two surfaces,

more resistance, and hence more heating and melting. Heavy

pressure between the parts translates to more contact between

the two surfaces, less resistance, and less heating.

Loading...

Loading...