Machine Manual Orion

Flex Stretchwrapper Revision 3.0

Troubleshooting 15 February 2016

Page 4-16

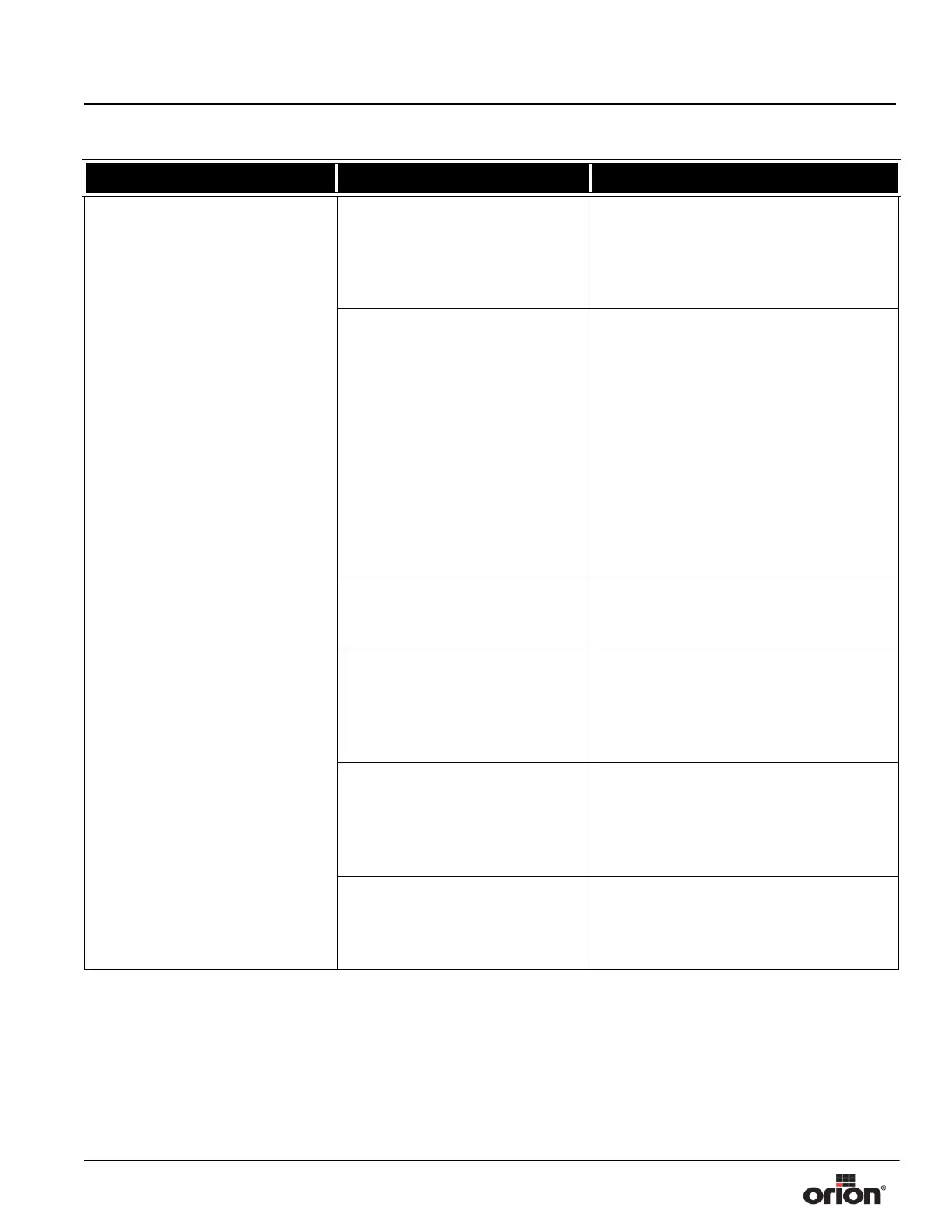

Film Cutter/ Brush Arm Not

Operating Properly

Brush extend timer at the touch-

screen is incorrect for the applica-

tion.

Look for the arm to activate smoothly, but

at the wrong time.

Observe the factory preset value on the

settings screen. Re-adjust the brush extend

timer as needed.

Air pressure to the machine is too

low.

Observe the pressure gauge at the pressure

regulator behind the lower rear access

panel.

Air supply to the machine should be 80

PSI @ 3CFM.

Air cylinder flow controls are set

incorrectly.

If the regulator shows correct pressure, the

flow controls are suspect.

Check the flow controls by manually acti-

vation of the cutter jog function on the

touchscreen. Adjust the flow controls on

the clamp cylinders so that they operate

smoothly.

Air lines are pinched or

obstructed.

observe all 1/4 inch polyflow tubing.

Remove any obstruction. Correct any

pinched lines.

Debris or condensation is in the

air lines.

Purge the air filter / regulator.

If water appears, then condensation is in

the air lines. Correct the water issue, then

purge the air lines by manually jogging

the cutter/ brush until no water remains.

Break in the wiring to the cutter

solenoid.

There is DC voltage at the cutter PLC out-

put, but no voltage at the cutter/ brush

solenoid.

Locate and repair break in the signal wir-

ing between the PLC and solenoids.

Cutter / brush solenoids are defec-

tive

There is DC voltage at the cutter / brush

solenoids but the solenoids do not acti-

vate.

Replace the cutter/ brush solenoids.

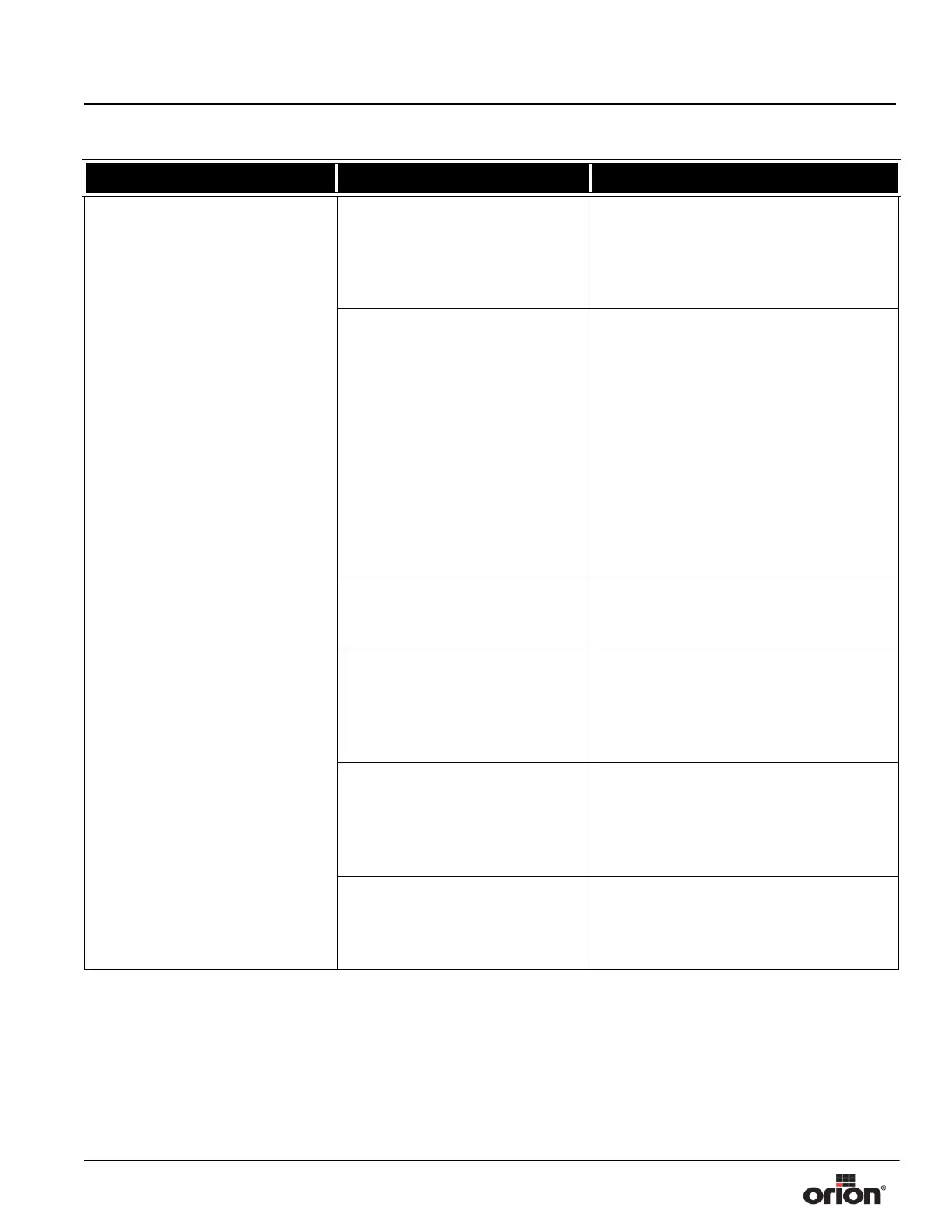

Table 4-1. Troubleshooting Chart (Continued)

PROBLEM POSSIBLE CAUSE SOLUTION

Loading...

Loading...