i Series User Manual

18

state for an abnormally long time may require a longer post-flow delay to maintain good shielding at the weld spot.

Purge - Touch this button to send a shot of shielding gas through the gas flow system. is is used to test if gas is flowing

through the system properly, to check the pressure, and to clear the gas line of any oxygen that may have entered between

welds.

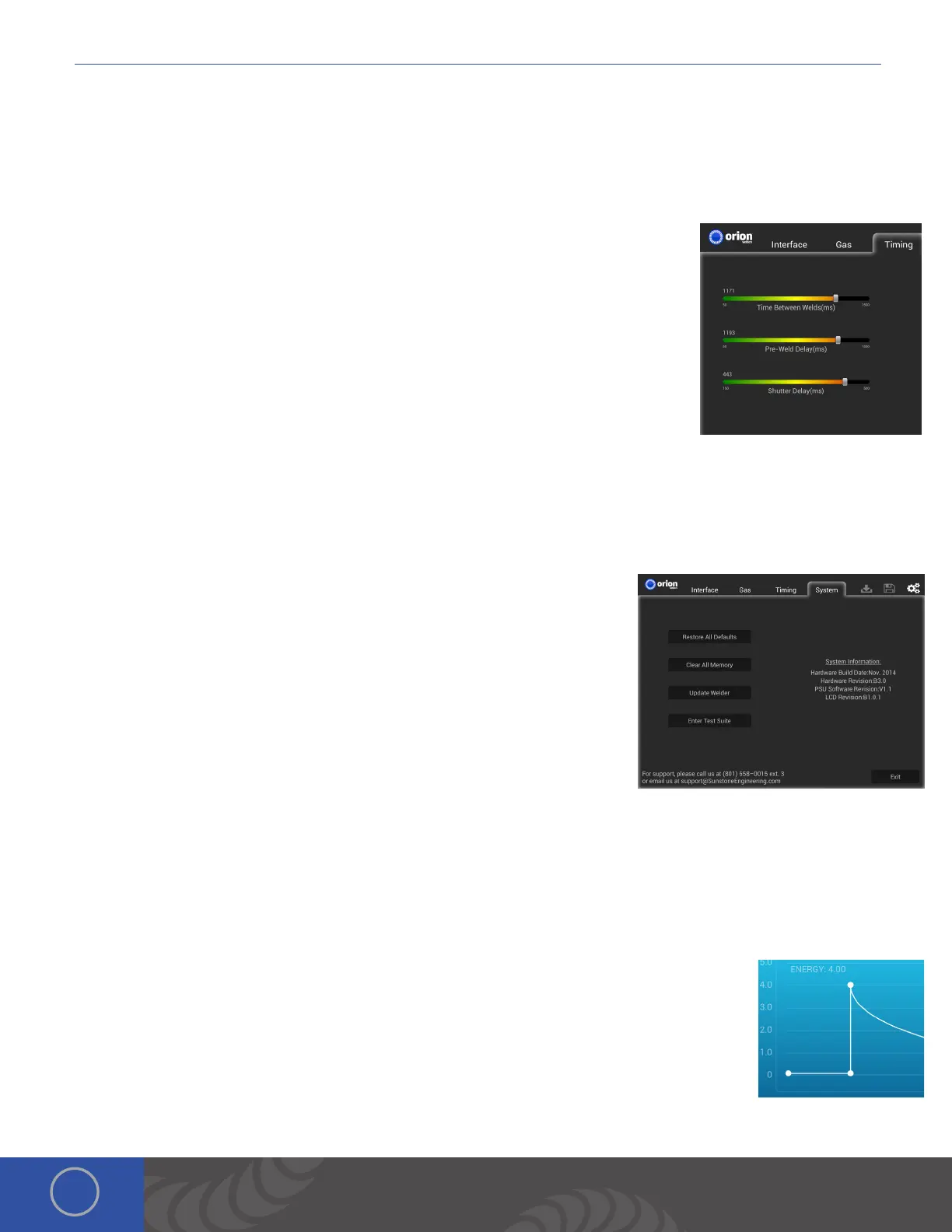

TIMING TAB

e Timing Tab allows users to control the amount of time used on different weld

parameters.

Time Between Welds - is sets the minimum or maximum time the welder waits before

another weld.

Pre-Weld Delay - is is the time from the moment the weld is initiated (either by

compressing the foot pedal or touching the work-piece to the electrode) to the time the

weld process begins. Shorter time will cause the weld process to begin immediately. Longer

time will cause the weld to have a noticeably extended delay before it welds. As such, other

factors add to this delay for a total time between trigger and weld energy release (i.e. Gas Delay settings).

Shutter Delay - is option controls how long the shutter in the microscope will stay shut after the weld has completed.

Even at the shortest time setting, the shutter will remain closed for the duration of the weld and protect the eyes of the user

from the weld flash.

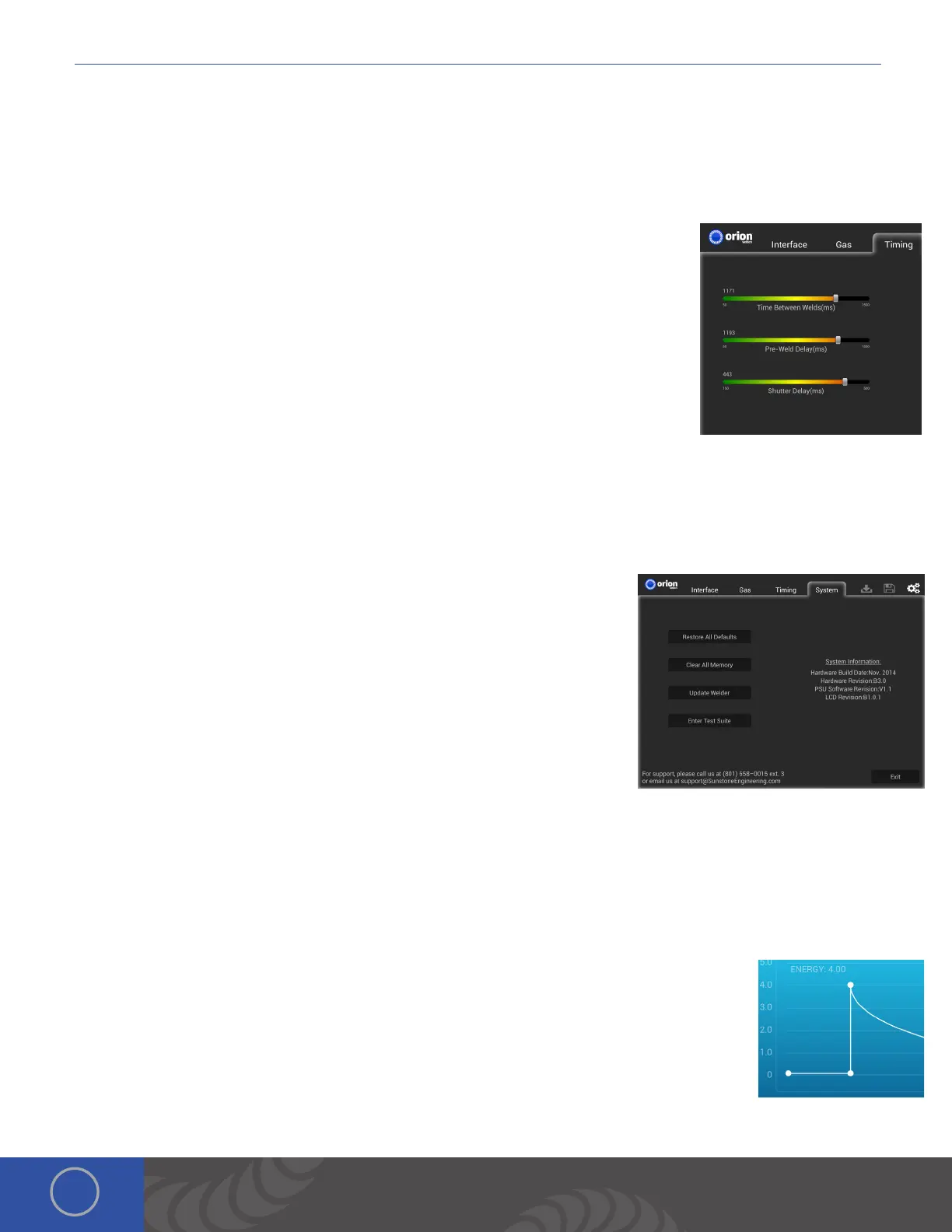

SYSTEM TAB

Restore All Defaults - is will reset all welder settings back to their factory

default settings. is will not affect saved settings.

Clear All Memory - is button will erase all the users Saved settings. *is can

take up to 45 seconds

Update Welder - When updating the welder, insert the USB stick into the USB slot

on the side of the welder and then touch this button.

Chapter 3: Reading the Waveform Graph

Ignition

STANDARD WELD IGNITION:

In Standard weld ignition mode, the timing is arranged so the weld starts on the surface of the

work-piece as the electrode is lifting off.

Advantages: is is very useful for tight/difficult weld joints because it insures that the weld is

located exactly where the electrode is touching.

Disadvantages: Due to the fact that the electrode is touching the weld surface when the main

welding pulse is turned on, molten material can accumulate more frequently on the electrode. is metal build up on the

electrode reduces its effectiveness over time and can require more frequent electrode sharpening/cleaning.

Loading...

Loading...