Operator Manual

Maintenance

Replacing the focal lens protective glass slide

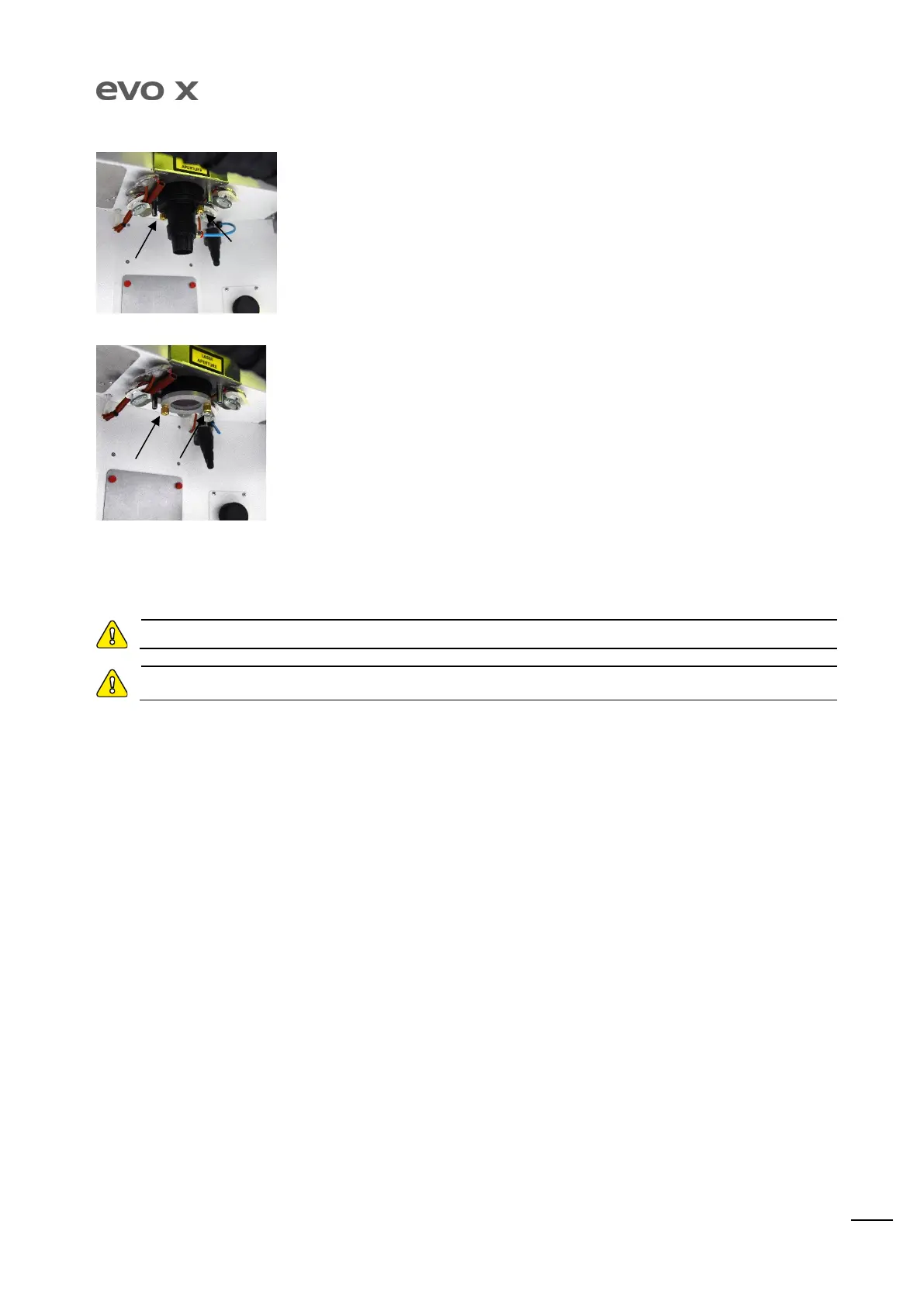

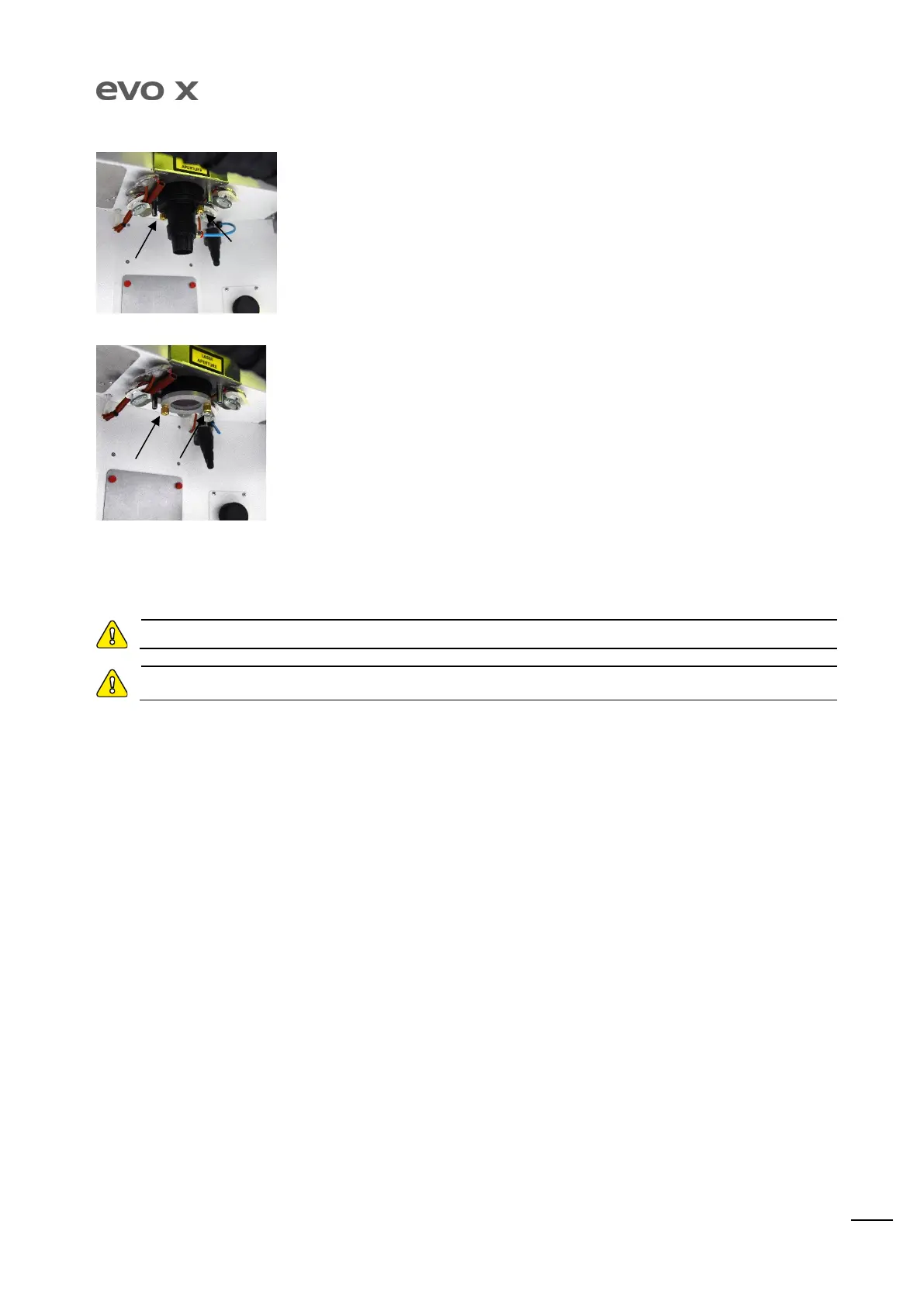

Check the status of the glass slide inside the welding chamber at least once a month. To

remove the glass slide support, loosen the 2 brass pawls indicated in the photo. If the glass

slide is marked by sprays of metal, is scratched, cracked or broken, replace it with a new one

(Code ATE00043).

Glass slide support with gas conveyor

When using the standard glass slide support, the blue gas pipe must be pushed inside the

machine for a few centimetres, in a way that the laser does not hit the pipe.

Standard glass slide support

WARNING! If the glass slide is very dirty, the power of the equipment may be reduced by up to 60% with respect to normal performance. If the

glass slide is damaged or broken, there can be serious consequences for the focal lens positioned above it.

Lack of maintenance of the filters can compromise equipment performance.

Do not cover the vents with cloths or other materials. Leave a space of at least 10 cm between the vents and the walls. The efficiency

of the Laser Welder could be compromised.

Loading...

Loading...