24

translation

7 MAINTENANCE OF THE MACHINE

Note! Always stop the machine before servicing.

7.1 Crosscut saw-blade

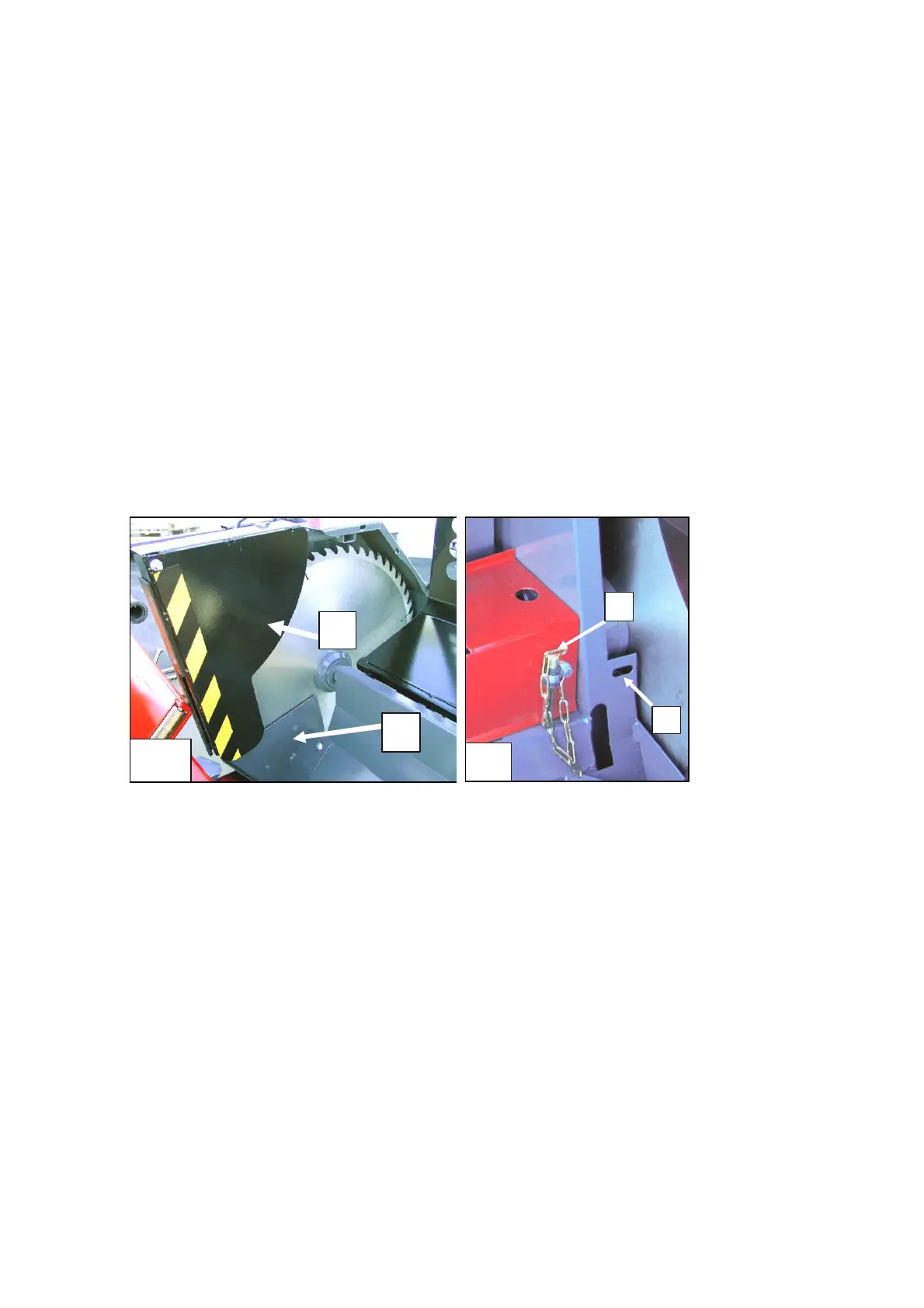

7.1.1 Removing the crosscut saw-blade (Figures 23 and 24)

1. Loosen the side plate of the sawdust trough A (a 17 mm spanner).

2. Remove the side plate of the saw-blade cover (13 mm spanner) and the blade

cover (17 mm spanner).

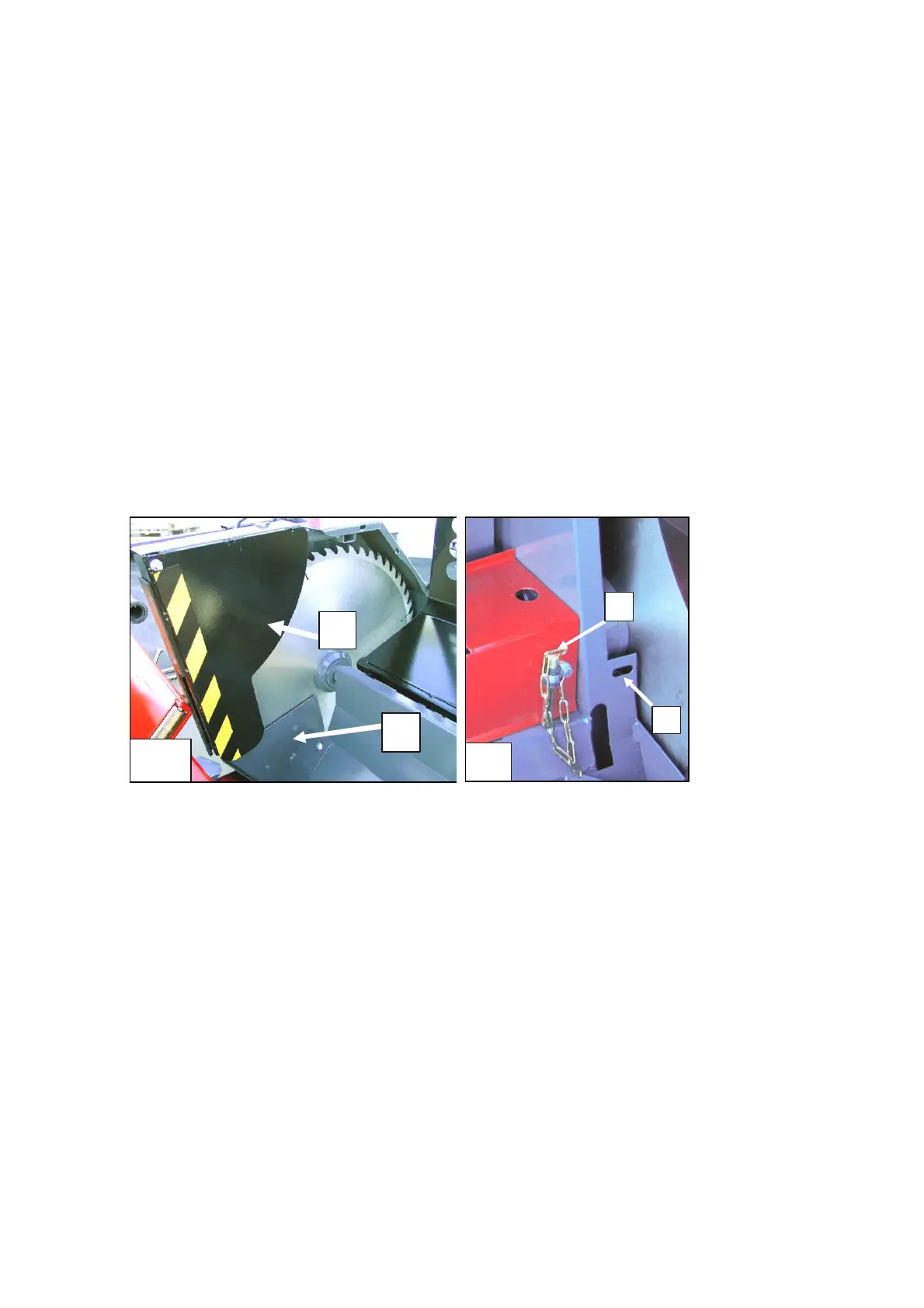

3. Put pin A into hole B indicated by the arrow (Figure 24) to prevent the saw-

blade from rotating and twist open the saw-blade nut (right-handed thread, 36

mm spanner). The thread on the nut is M 24 x 2.

4. Carefully clean the surfaces of the flanges before re-installation of the blade.

5. Before installing the blade, make sure that the pin, which prevents the saw-

blade from rotating, is in place.

A

B

Fig. 23. Removing the crosscut saw-blade

1/2

24

B

A

Fig. 24. Removing the crosscut saw-blade

2/2

7.1.2 Sharpening the chain

The hard-metal blade can be sharpened "lightly" using a diamond file.

Depending on the cleanliness of the wood, as many as 5001000 bulk cubic metres

of wood can be processed with a hard-metal saw-blade without resharpening.

The best sharpening result and durability of the blade is achieved when the saw-

blade is sharpened using an appropriate grinding machine and a diamond file.

7.1.3 Stressing the saw-blade

Stressing-faults do not usually occur in hard-metal blades, but if the blade is very

blunt such faults are possible. Always take such a blade to a professional saw-

blade service.

Loading...

Loading...