20

4.4 Common Precautions on Terminals for Control

Circuit

█

Precautions on wiring

· For wiring of terminals for control circuit, strip specified length of insulation coating

before connecting.

· Loosen terminal screws and insert wires from bottom of the terminal block, and

tighten screws to specified tightening torque.

· Any loose connection could cause wire to come off and lead to malfunction. Also,

over-tightening could cause short-circuit due to broken of screws or the unit, thus

leading to malfunction.

· Use shielded cables for all control signal lines and separate them from power lines or

high-voltage circuits (20cm or more).

· Wiring length of control signal lines should be within 30m.

· Since input signals of control circuit are feeble, use dedicated contact for feeble

signals to avoid poor contact during contact input.

█

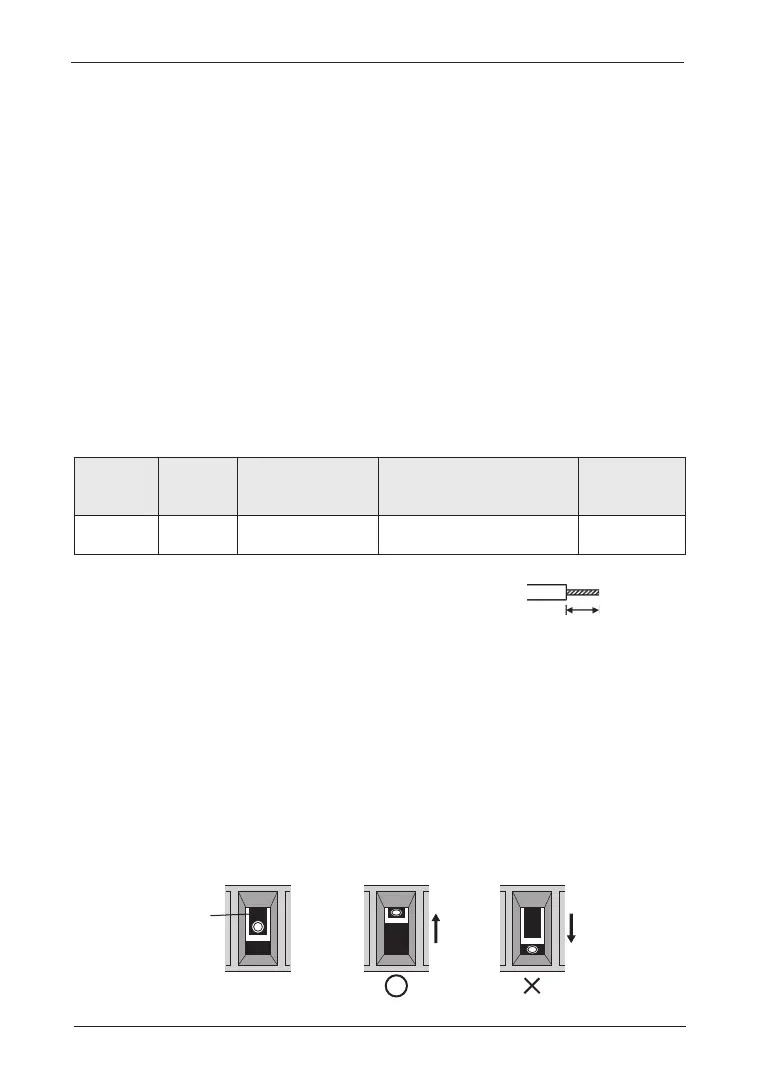

Wire size and tightening torque for control circuit terminal

Terminal

symbol

Screw

size

Tightening orque

N·m

Wire size

Stripped

length of

cable sheath

A,B,C

1

to

AR

M3 0.3 to 0.4

0.25mm

2

to 0.75mm

2

(AWG24 to AWG18)

6mm

· Screwdriver :Small-size ○- screwdriver · Stripped length of wir e sheath

(Thickness of the edge: 0.4mm/ Width of the edge: 2.5mm)

· Terminal block for main curcuit :

Terminal block for control circuit (Relay output/Signal input/output) :The maximam

number of the conductors : 2 *1

*1 The maximam number of the conductors should be made in the reach of the

suitable electric wire size.

█

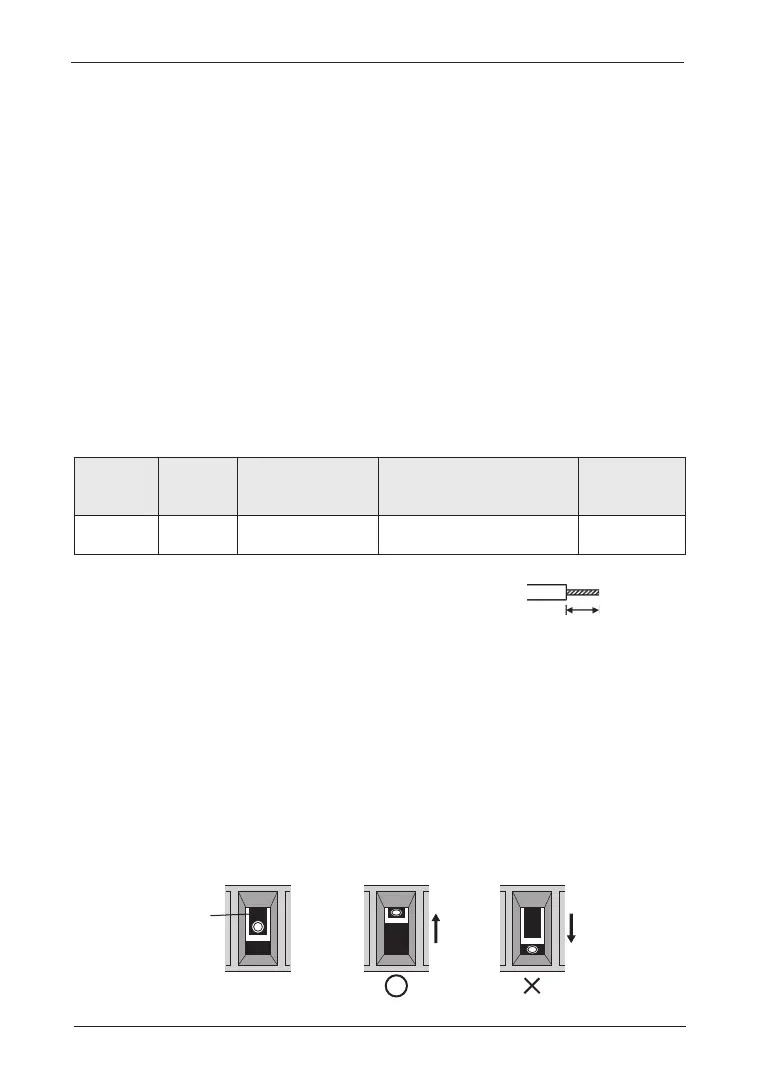

Precautions on wiring

Observe the following items to prevent wire breakage.

· Do not damage the core wire when tearing the insulation layer off.

· Connect the core wire together.

· Do not lift up the welded part of core wire. It may be broken by vibration.

· Do not apply force to cables after wiring.

· If the tightening direction of calbe in terminal block is CCW, it is wrong.

Remove the cable, and confirm the terminals before reconnect it.

CW CCW※Insert the calbe here.

(※)

Loading...

Loading...