6-3

6

* It is not necessary to disconnect the communications line in the inter-unit control wiring if it has already been con-

nected at this time.

* Settingmodes1and2canbeusedevenwhentheoutdoorunitisindependent(when1maintenanceremotecon-

troller is connected to 1 outdoor unit and automatic address setting for the indoor units has not been completed).

* Displays the overall system status for that refrigerant system.

All units start/stop (Fig. 6-1)

<Operation>

The

button can be used to start and stop all the indoor units.

• TheLEDturnsONwhen1ormoreindoorunitsisoperating.

• TheLEDblinkswhenanalarmhasoccurredat1ormoreindoorunits

during operation.

Switching between cooling/heating (Fig. 6-1)

<Operation>

The

button switches between heating and cooling modes.

• Thespecicationsareequivalenttotheheating/coolinginputthatwas

present on earlier outdoor unit PCBs.

• Thedisplayshowstheoperatingmodeoftheindoorunitwiththelowest

number.

All units test run (Fig. 6-2)

<Operation>

The

button switches test run ON/OFF for all indoor units.

• Pressandholdfor4secondstoturnON.

“Test run” is displayed while the test run is in progress.

• Conditionsoftestrunsthatarestartedfromtheunitremotecontrollerare

not displayed on the outdoor unit maintenance remote controller.

6-3. Normal Display Operations and Functions

Normal display functions

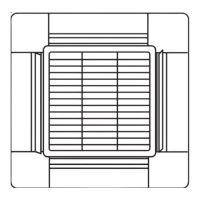

• ConnectthespecialservicecheckerwiringtotheoutdoorunitPCB.

Theconnectionisshowninthegurebelow.

Specialservicecheckerwiring

Relay connector (2P, white)

Interface for outdoor unit maintenance

remotecontroller(Optional,ServicingNo.CV6233039848)

PCBconnector(3P,blue)

PCBconnector(5P,red)

RC(5P,red)

Outdoor unit

control PCB

RemotecontrollerAssy

Fig. 6-2

Fig. 6-1

SM830194-04_Single_BigPAC.indb 3 2014/10/31 13:21:21

Loading...

Loading...