MSG11-5715-662 DCV UK.indd 21.07.22

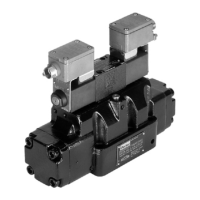

Directly operated and pilot operated directional control valves

Series D1VW / D1DW / D3W / D3DW / D31DW / D41VW / D81VW / D91VW

10

Translation from German

Parker Hannin Corporation

Before commissioning, the specialist

personnel must verify that the entire

hydraulic system has been installed

correctly. Commissioning must be car-

ried out with care, taking account of all

safety regulations.

If necessary, erect warning signs to prevent unin-

tended operation.

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

Installation instructions DCV

Before installation, check the outer O-rings

to ensure they are intact and complete. Dam-

aged parts of O-rings may impair the function

of the valve and must not be installed. Lifting

and installation equipment should be used as

necessary for installation.

After placing the valve on the mating surface,

tighten all bolts diagonally and evenly in sev-

eral passes, to the torque specied by the

manufacturer. The rst time the valve is pres-

surised, check the sealing surface for leaks.

Electrical connections

Before commissioning,

• all electrical connections must be made profes-

sionally, using suitable ducting;

• parts of the machine and individually installed

components must be adequately earthed;

• all limit switches and control elements must

be properly integrated with the control system.

Hydraulic requirements for pilot operated di-

rectional control valves

To guarantee that the main piston operates reliably

at all times, the minimum pilot pressure must be

provided. To achieve this, a suitable combination

of ow and return arrangements must be selected

for the pilot oil.

With piston 030 there is a brief connection

from P to T in the transitional position. An

external pilot oil supply or an integrated

precharge valve must be used in order to

guarantee reliable valve operation even

at low ows.

9. Operation

If any of the safety features of the product

are not operational, the system/machine

must be shut down immediately.

Do not carry out any activities that might

jeopardise safety.

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

10. Troubleshooting

A systematic approach must always be used in the

troubleshooting process. Begin by answering the

following questions:

• Does anyone have practical experience of

similar faults?

• Have any of the settings been changed in the

system/machine?

• Was the system/machine in perfect working

order before the fault occurred?

The following list contains the problems that are

possible in our view:

Loading...

Loading...