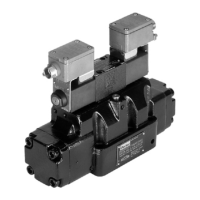

Directly operated and pilot operated directional control valves

Series D1VW / D1DW / D3W / D3DW / D31DW / D41VW / D81VW / D91VW

9

Translation from German

Parker Hannin Corporation

MSG11-5715-662 DCV UK.indd 21.07.22

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

7. Storage

If the product needs to be temporarily stored, it

must be protected from dirt, the weather, and dam-

age. Each valve is tested with hydraulic oil in the

factory, so that the internal components are pro-

tected from corrosion. However, this protection can

only be guaranteed under the following conditions:

Storage time: Conditions:

12 months

Stable air humidity 60 %

and stable temperature

>5 °C - <25 °C

6 months

Fluctuating air humidity and

uctuating temperature

>5 °C - <35 °C

The product is delivered with adequate corrosion

protection, provided our recommendations for the

ambient conditions are followed.

Storage outside or in maritime or tropical

climates without appropriate packaging

leads to corrosion and may make the

product unusable.

Make sure the product is stored so that

no injuries can be caused by tipping or

falling. In particular, make sure that the

safety rules for high-bay racking are

followed.

8. Commissioning

After installing our product in a system/machine,

make sure that the requirements of the Machinery

Directive are met if applicable.

Access should be provided to the hydraulic dia-

gram, the equipment list and the logic diagram for

the system/machine.

The product must be checked for dam-

age and missing parts (e.g. seals) before

installation, especially in the area of the

sealing surfaces and the safety devices.

If the safety devices or sealing surfaces

are damaged or are missing individual

parts with relevance to the product's

function, the product may not be used.

Remove all transport securing devices, protective

covers and packaging.

Check for foreign objects in the open

hydraulic passages. Contaminations

may impair operational reliability and

shorten the service life.

Make sure that the hydraulic system/

machine is unpressurised before the

product is installed.

Use the nameplate to compare the valve type with

the bill of materials/diagrams.

Take care during installation, to guarantee that

all requirements for the safe use of the product

are met.

Ensure that the sealing rings are seated correctly.

Only use the fastening bolts specied by the manu-

facturer for installing the product (see "Technical

data", section 16.). The user should check again if

additional components are added to the valve (e.g.

sandwich plates)

Use the correct tool for installing the fastening

bolts.

Install the fastening bolts to the torques

specified by the manufacturer (see

"Technical data", section 16.). Tighten

the bolts diagonally.

If the seal of the position control system

is damaged, there is a risk that the valve

will not work properly. In this case, the

valve must be returned to the manufac-

turer.

The DCV valves must only be installed

as indicated in ISO 4401.

Loading...

Loading...