MSG11-5715-662 DCV UK.indd 21.07.22

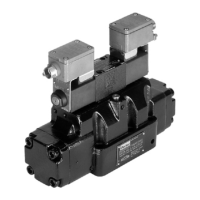

Directly operated and pilot operated directional control valves

Series D1VW / D1DW / D3W / D3DW / D31DW / D41VW / D81VW / D91VW

12

Translation from German

Parker Hannin Corporation

11. Modication

We dene modication as the replacement of a

defective valve with a new valve of the same series.

In particular, it is not permitted to open the valve.

Make sure that the hydraulic system/

machine is unpressurised before the

product is installed/removed.

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

12. Service/maintenance

Regular maintenance is essential in prolonging the

service life of the system/machine, and safeguards

plant safety and the operational availability of all

components.

Regular maintenance intervals must be adhered

to, according to the cycles established for the user.

The minimum maintenance requirements

for our products are visual inspections

• to check the integrity of the seal at

position control

• to check for leaks

• and to check that the plugs are properly

secured.

Make sure that the hydraulic system/

machine is unpressurised before the

product is installed/removed.

If the product is removed from the sys-

tem/machine for maintenance work, the

system/machine must be disabled so it

cannot be switch on unexpectedly.

Before checking or removing electrical

connections, make certain that the power

supply has been disconnected and steps

have been take to ensure it cannot be

reconnected unintentionally.

As part of servicing/maintenance, only the fol-

lowing items can be replaced with original Parker

replacement parts:

• Accessible O-rings (sealing surfaces)

• Solenoid coils

• Plugs, provided they were included with the

original product

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

13. Decommissioning

Make sure that the hydraulic system/

machine is unpressurised before the

product is removed.

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

14. Disposal

At the end of the service life of this

product

• all escaping pressure uids must be

removed and disposed of properly

• any signicant uids remaining in the

product must be removed and disposed

of properly

• all materials must be segregated for

recycling when they are removed and

taken to a suitable recycling centre.

Please segregate the packaging material properly

(e.g. paper, plastic).

None of the components of the product contain

hazardous materials.

The normal local environmental protec-

tion laws must always be met when

disposing of the product.

Note also the information in sections 1. "Warranty

and liability", 2. "Use of operating instructions", 2.

"Compliance with other rules and instructions", 2.

"Personnel requirements" and 3. "Remaining risk".

Loading...

Loading...