MSG11-5715-662 DCV UK.indd 21.07.22

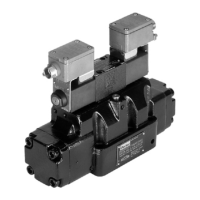

Directly operated and pilot operated directional control valves

Series D1VW / D1DW / D3W / D3DW / D31DW / D41VW / D81VW / D91VW

6

Translation from German

Parker Hannin Corporation

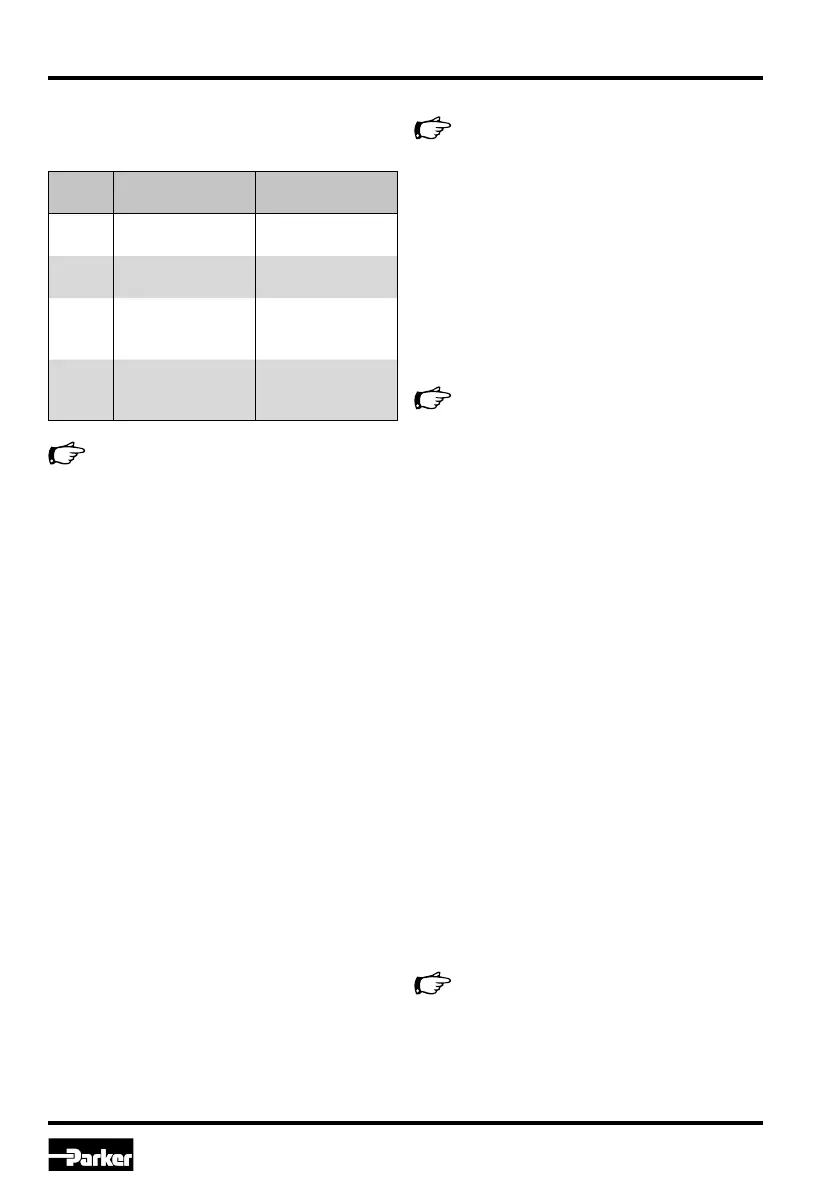

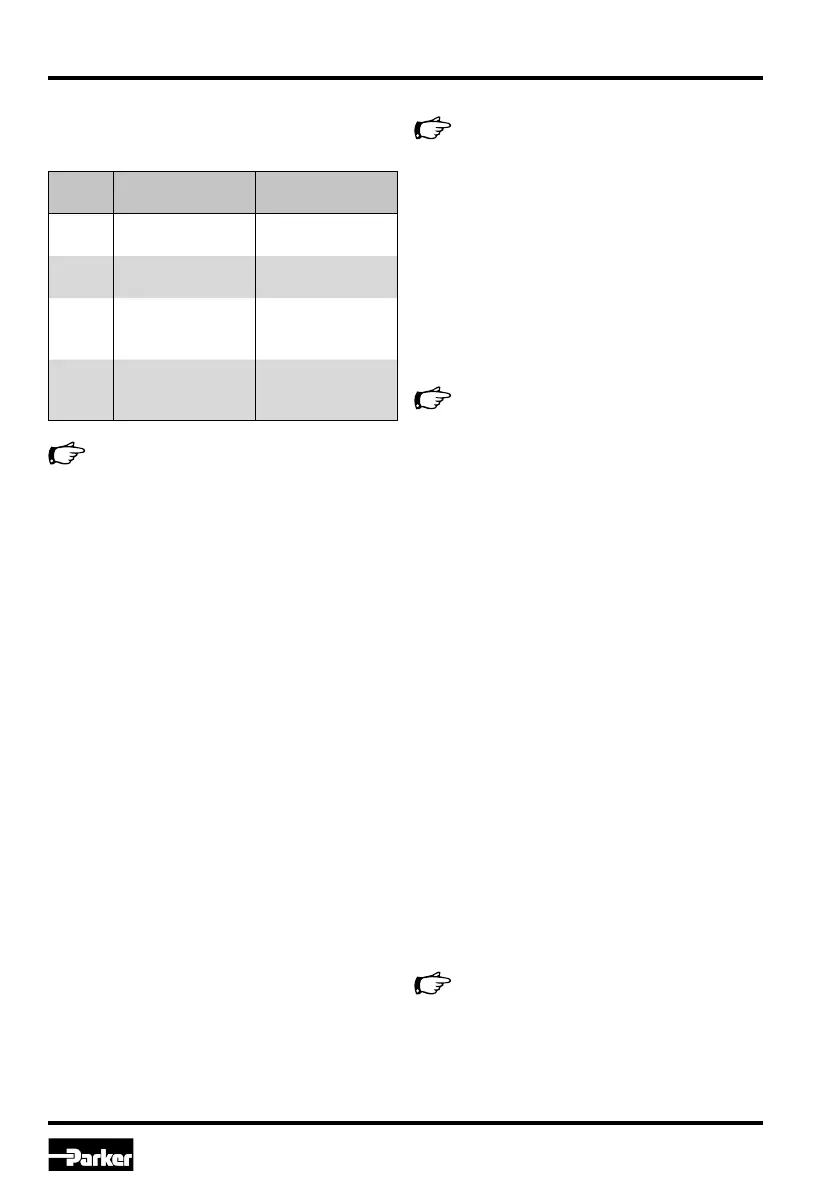

Pressure uids

Certain rules apply to valve operation using dier-

ent pressure uids:

Mineral

oil

No restrictions

HFA

Oil in water

emulsions

Mandatory check

HFB

Water in oil

emulsions

Mandatory check

HFC Water glycols

Possible restric-

tions, recommend-

ed check

HFD

Anhydrous uids

(phosphate ester)

Possible restric-

tions, recommend-

ed check

The details of the various pressure uids

are provided for information only and do

not replace in-house testing under the

applicable operating conditions. In par-

ticular, the details cannot be interpreted

as a guarantee of media compatibility.

For detailed information about pressure

uids, see VDMA sheet 24317 and DIN

51524 51502. Special sealing materials

are supplied depending on the uid used.

Please ask the factory if you are unsure.

After a certain period of service, the hydraulic uid

must be replaced. The frequency of the change

depends on the following:

• Type and grade of pressure uid (ageing)

• Filtration

• Operating temperature and ambient conditions

Flushing

With large central pressurised oil stations

in particular, you are recommended to

ush the long pipes by short circuiting

the pressure and return lines. This pre-

vents the dirt occurring during installa-

tion from being carried to the valve.

Product support

If you require further support about the product,

about order processing or about solutions to prob-

lems, please contact your relevant sales company.

2. General notes on safety

Use of operating instructions

We would again like to remind you that

the commissioning and use of our prod-

uct must be based on these operating

instructions. They must

• be followed in full at all times,

• be kept in close proximity to the in-

stalled product, and be accessible at

all times,

• be passed on to any later owners,

• always be used in the version supplied.

The personnel whose job is to work with

this product must have read the operating

instructions – in particular the section en-

titled "General notes on safety" – before

starting work. This specically applies

to personnel who will only work with the

product occasionally (e.g. setting up,

maintenance).

Compliance with other rules and instructions

Carry out transport and installation/repair activities

only in accordance with the valid and applicable

safety and accident prevention regulations issued

by the trade associations.

The valve contains hydraulic oil. The normal lo-

cal environmental protection requirements must

therefore be met when handling the product.

The particular circumstances of each place of in-

stallation mean that instructions must be followed

in order to install and use the product safely.

Any health and safety warnings attached

to the product must be observed and

must be maintained in a legible state.

Air Bleeding of Hydraulic System

During initial startup, after an oil change as well as

after the opening of lines or valves the hydraulic

system must be air bleeded.

Loading...

Loading...