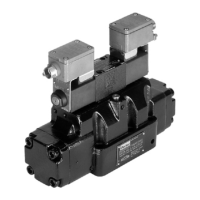

Directly operated and pilot operated directional control valves

Series D1VW / D1DW / D3W / D3DW / D31DW / D41VW / D81VW / D91VW

7

Translation from German

Parker Hannin Corporation

MSG11-5715-662 DCV UK.indd 21.07.22

Personnel requirements

The product may only be used, installed, removed,

operated and maintained by specialist personnel.

For the purposes of these instructions, a specialist

is dened as someone who, on the basis of their

education, expertise and professional experience,

is able to correctly evaluate and carry out the tasks

and duties assigned to him/her, and identify and

correct potential hazards.

Skilled, semi-skilled or trained personnel may not

use this product under their own responsibility un-

less they have the required specialist knowledge.

Otherwise, they may only use the product under

the constant supervision of a specialist person.

Use of the product

The product must only be used if it is perfect work-

ing order. Problems that may impair safety must

be corrected.

This product is a safety component that

may only be repaired by the manufacturer

if it malfunctions.

If the safety components are repaired by

the user, the manufacturer's warranty is

invalidated because the manufacturer is

demonstrably unable to ensure that the

product is used as specied.

Limits of use

The product may only be operated within the speci-

ed limits of use. The relevant details can be found

in "Technical data" (section 16).

The ambient conditions must be ob-

served. Unauthorised temperatures,

shocks, the effects of aggressive

chemicals, radiation, unauthorised

electromagnetic emissions may result

in disruptions and failures.Observe the

limits of operation set out in "Technical

data" (section 16).

DCV valves with position control are not

suitable for use in Ex areas (gas/dust).

Contaminations

The function and service life of the valve are heavily

dependent on the purity and quality of the pressure

uid and depend upon the operating conditions of

the hydraulic components.

Appropriate lters must be used and regular in-

spections of the medium must be carried out to

prevent contamination of the pressure uid. The

permitted level of contamination is set out in the

"Technical data".

Be aware of three important sources of

contamination:

• Contaminations entering during instal-

lation

• Contaminations occurring during operation

• Dirt entering from the surroundings

3. Remaining risk

Allergic reactions

Hydraulic oil can cause allergic reactions on sus-

ceptible skin. This can be prevented by taking the

precautions that are usual when handling min-

eral oil products and by using personal protective

equipment.

Leaking plugs

Leaking plugs can cause a malfunction.

That is why the plugs must be checked

for leaks at the regular maintenance

interval. Leaking plugs may constitute

a safety hazard, so the valve must be

returned to the manufacturer for repair.

Lightning

If electronic components are exposed

to electromagnetic elds as a result of

lightning, they must be checked to ensure

they are still working perfectly. If there

is a malfunction, the product must be

returned to the manufacturer.

Loading...

Loading...