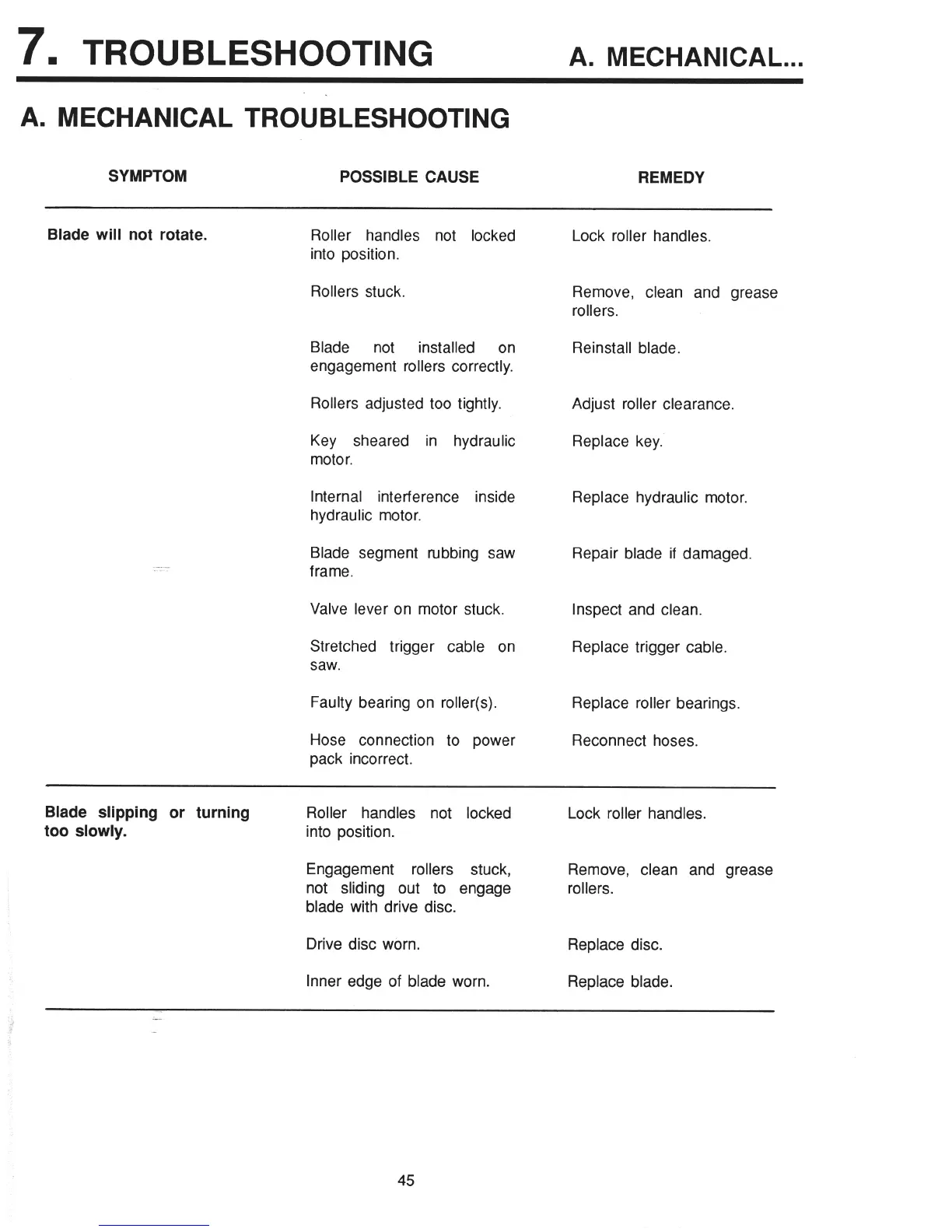

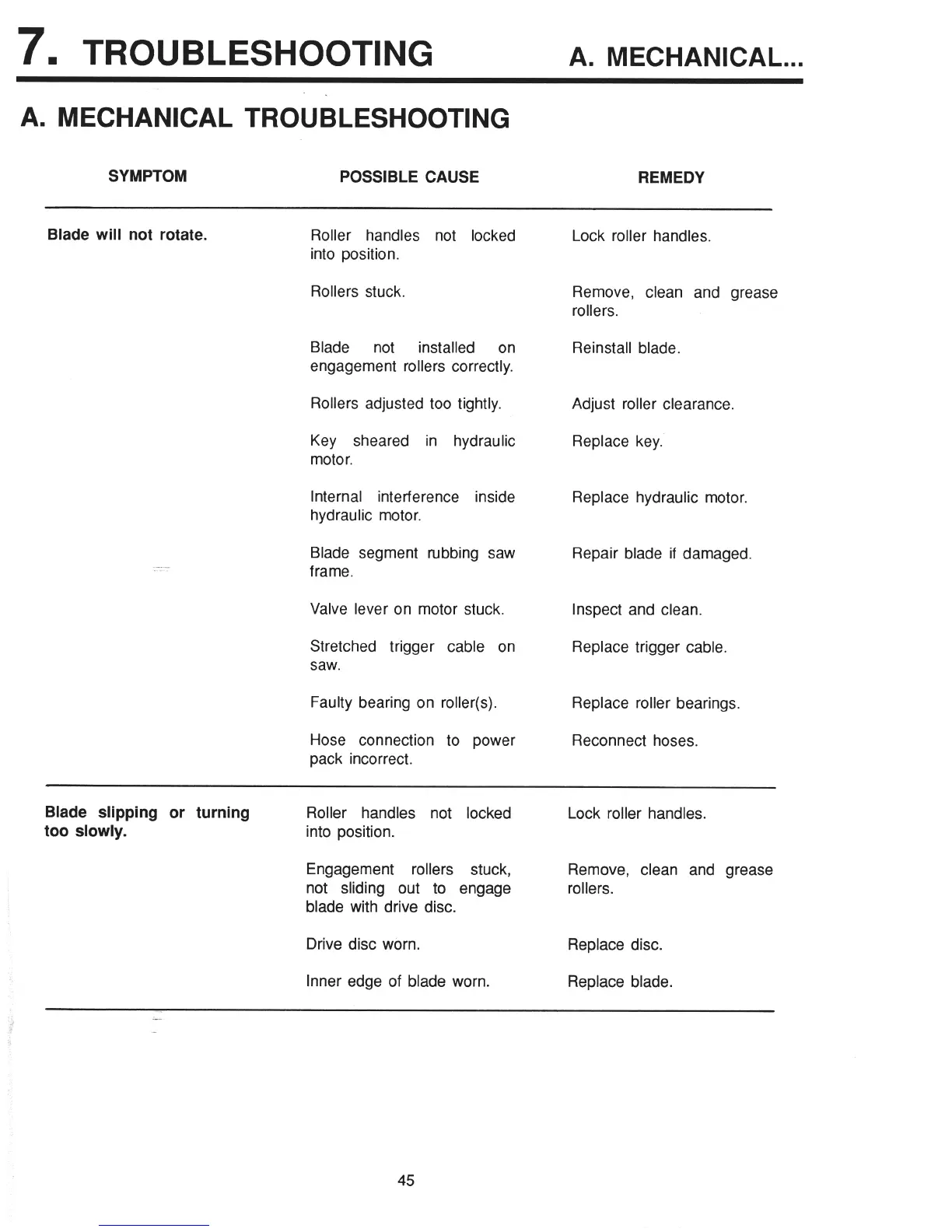

: A. MECHANICAL TROUBLESHOOTING

SYMPTOM

POSSIBLE CAUSE

REMEDY

Blade will not rotate.

Roller handles not locked

into position.

Lock roller handles.

Rollers stuck. Remove, clean and grease

rollers.

Blade not installed on

engagement rollers correctly.

Reinstall blade.

Rollers adjusted too tightly. Adjust roller clearance.

Key sheared in hydraulic

motor.

Replace key.

Internal interference inside

hydraulic motor.

Replace hydraulic motor.

Blade segment rubbing saw

frame.

Repair blade if damaged.

Valve lever on motor stuck.

Inspect and clean.

Stretched trigger cable on

saw.

Replace trigger cable.

Faulty bearing on roller(s).

Replace roller bearings.

Hose connection to power

pack incorrect.

Reconnect hoses.

Blade slipping or turning Roller handles not locked

too slowly. into position.

Lock roller handles.

Engagement rollers stuck,

not sliding out to engage

blade with drive disc.

Remove, clean and grease

rollers.

Drive disc worn. Replace disc.

-

Inner edge of blade worn.

Replace blade.

45

Loading...

Loading...