--

7. TROUBLESHOOTING

C. FAILED PARTS ANALYSIS....’

C. FAILED PARTS ANALYSIS

FAILED PART

POSSIBLE CAUSE

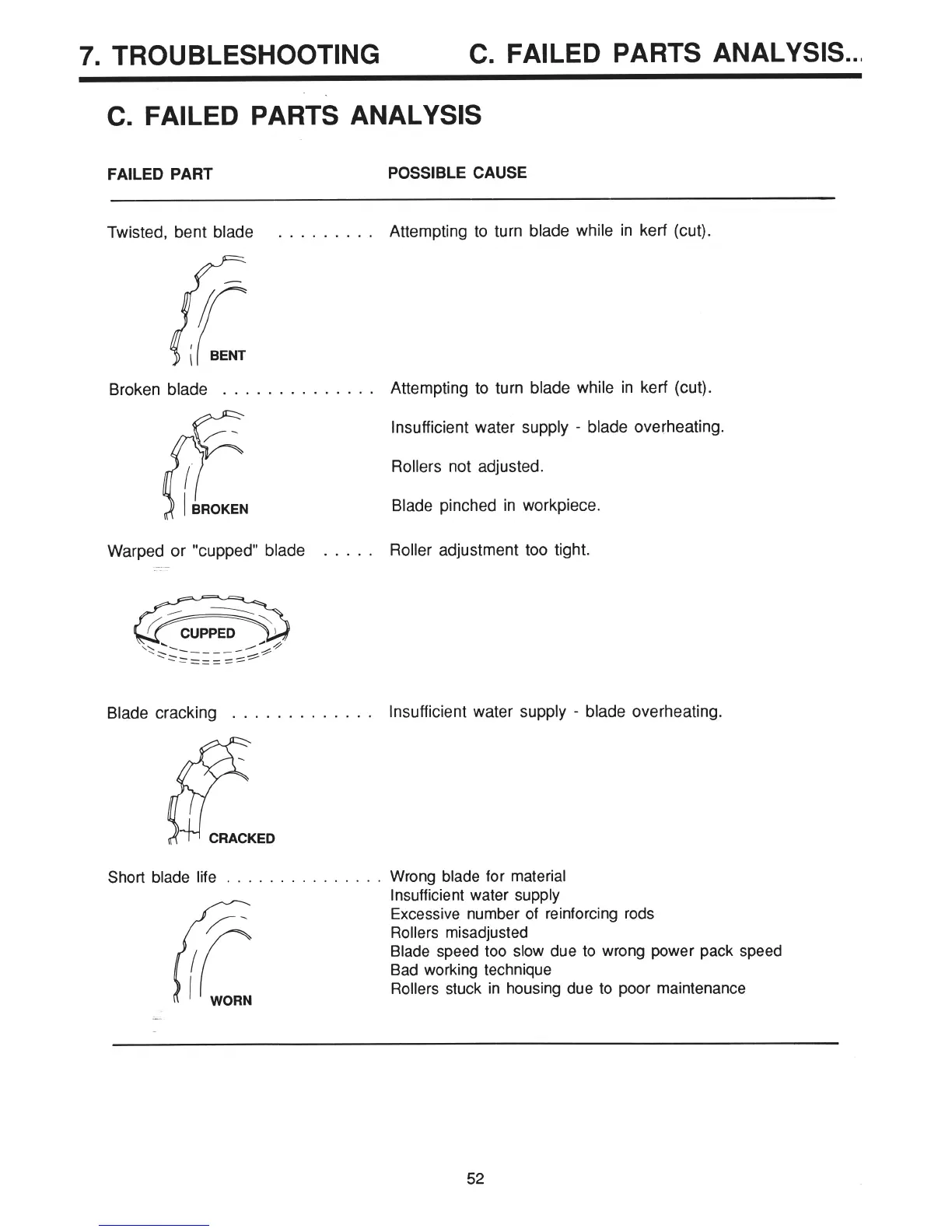

Twisted, bent blade . . . . . . . . .

Attempting to turn blade while in kerf (cut).

Broken blade . . . . . . . . . . . . . .

Attempting to turn blade while in kerf (cut).

Insufficient water supply - blade overheating.

Rollers not adjusted.

Blade pinched in workpiece.

Warped or “cupped” blade . . . . . Roller adjustment too tight.

--

($$zs$

‘2>------- //

-=-----‘c+

----

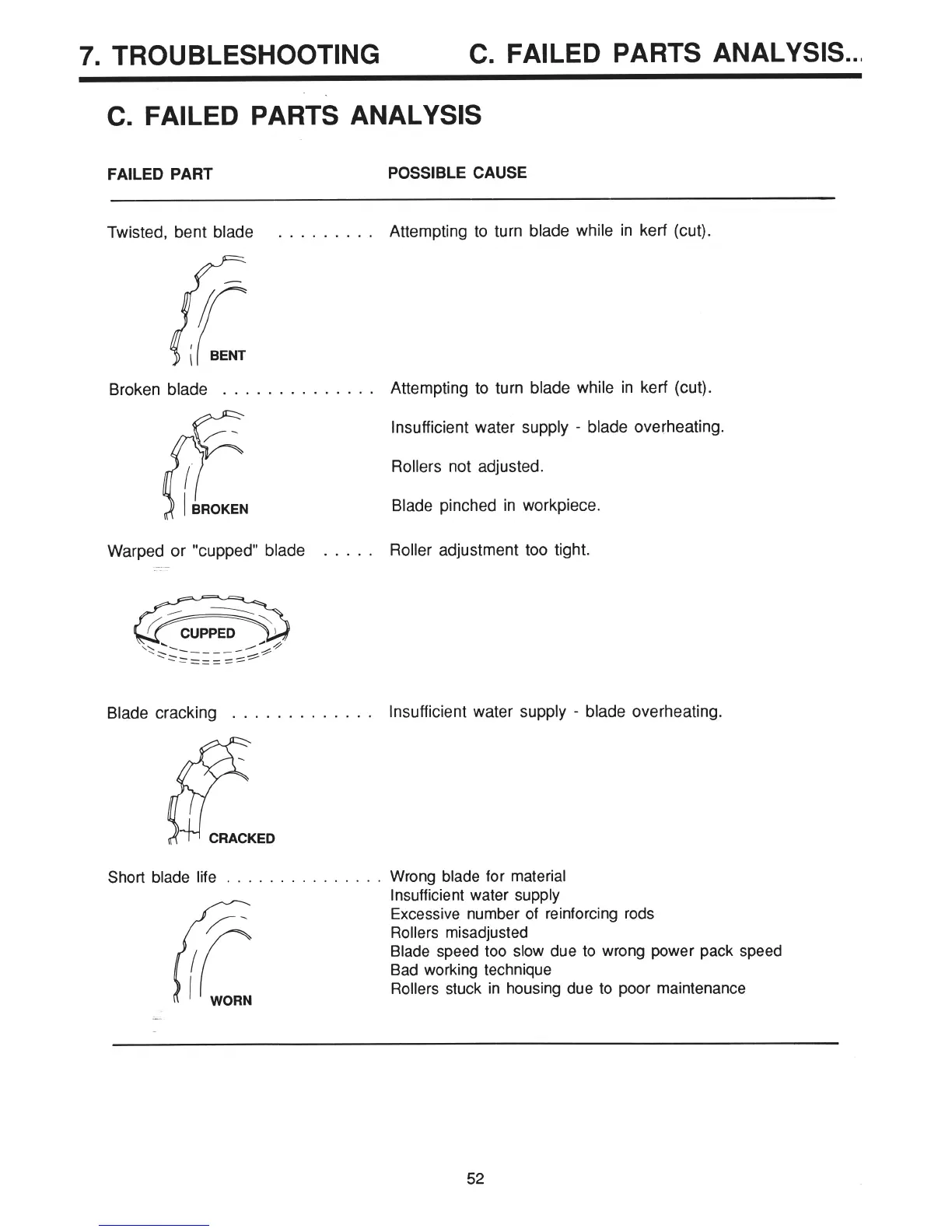

Blade cracking . . . . . . . . . . . . . Insufficient water supply - blade overheating.

F

CRACKED

Short blade life . . . . . . . . . . . . . . . Wrong blade for material

lnsuff icient water supply

Excessive number of reinforcing rods

Rollers misadjusted

Blade speed too slow due to wrong power pack speed

Bad working technique

Rollers stuck in housing due to poor maintenance

-

52

Loading...

Loading...