3.

THEORY OF OPERATION

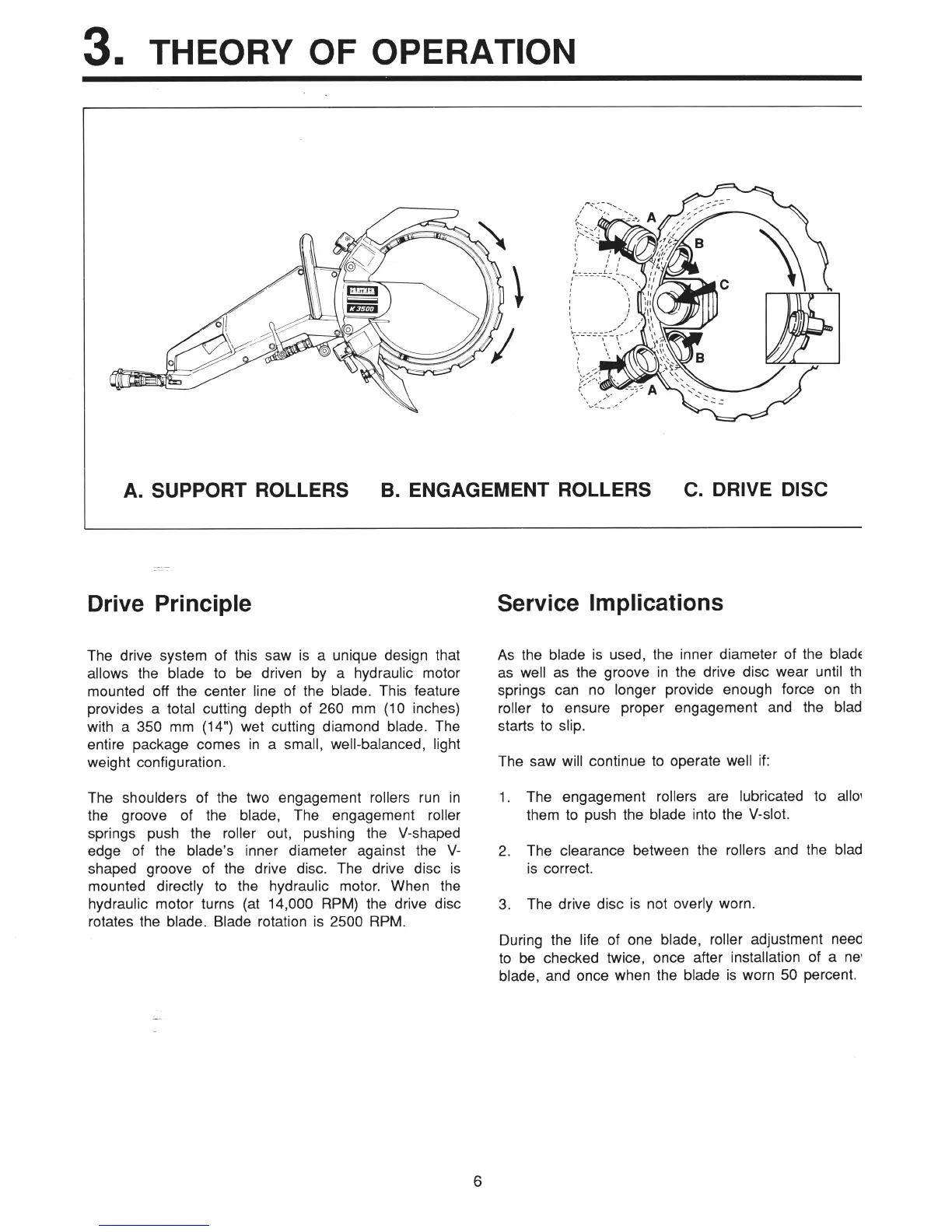

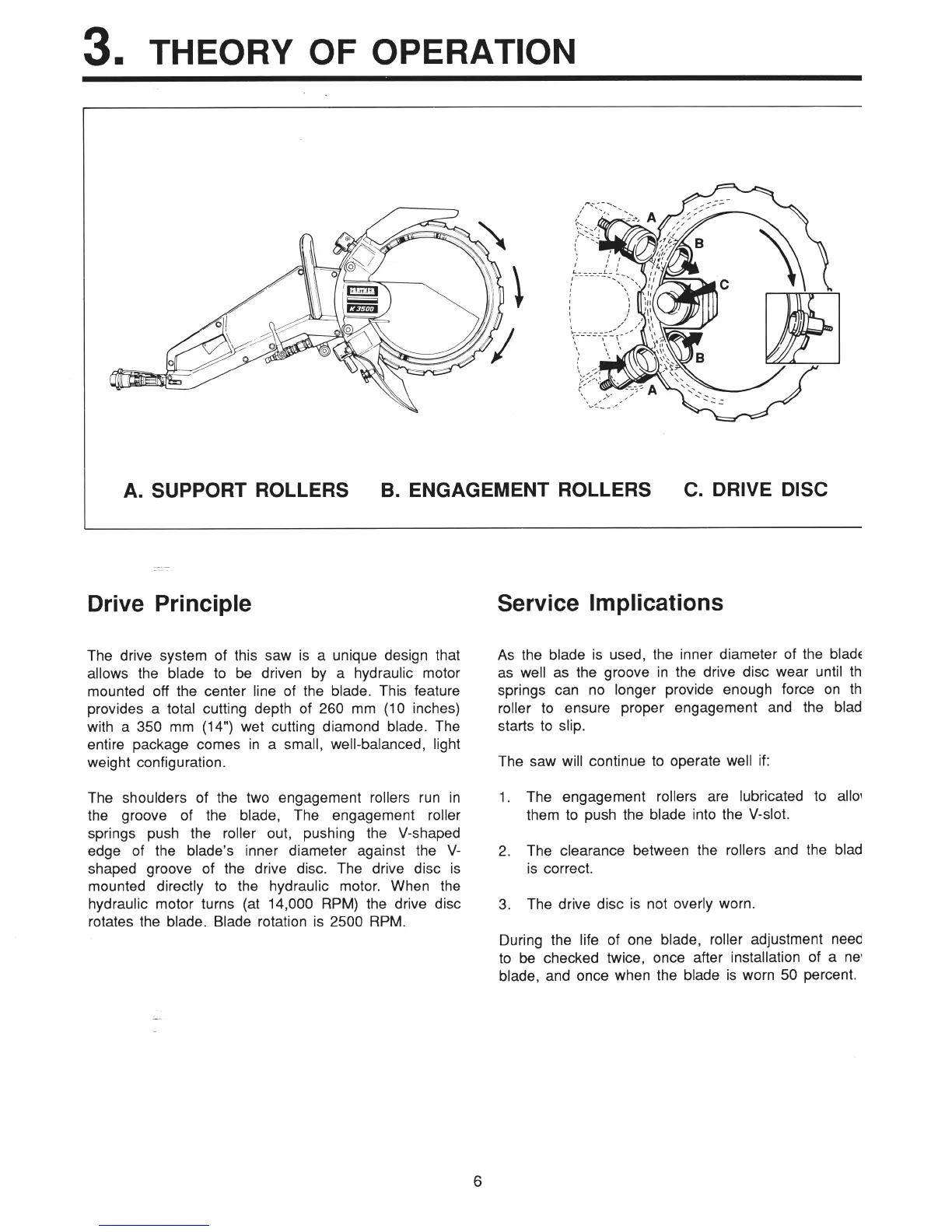

A. SUPPORT ROLLERS

B. ENGAGEMENT ROLLERS

C. DRIVE DISC

Drive Principle

Service Implications

The drive system of this saw is a unique design that

allows the blade to be driven by a hydraulic motor

mounted off the center line of the blade. This feature

provides a total cutting depth of 260 mm (10 inches)

with a 350 mm (14”) wet cutting diamond blade. The

entire package comes in a small, well-balanced, light

weight configuration.

The shoulders of the two engagement rollers run in

the groove of the blade, The engagement roller

springs push the roller out, pushing the V-shaped

edge of the blade’s inner diameter against the V-

shaped groove of the drive disc. The drive disc is

mounted directly to the hydraulic motor. When the

hydraulic motor turns (at 14,000 RPM) the drive disc

rotates the blade. Blade rotation is 2500 RPM.

As the blade is used, the inner diameter of the blade,

as well as the groove in the drive disc wear until the

springs can no longer provide enough force on the

roller to ensure proper engagement and the blade

starts to slip.

The saw will continue to operate well if:

1. The engagement rollers are lubricated to allow

them to push the blade into the V-slot.

2. The clearance between the rollers and the blade

is correct.

3. The drive disc is not overly worn.

During the life of one blade, roller adjustment needs

to be checked twice, once after installation of a new

blade, and once when the blade is worn 50 percent.

-.

6

Loading...

Loading...