5. SET-UP & ADJUSTMENTS

C. DRIVE DISC

C. DRIVE DISC

NOTE: If the blade slows or stops

momentarily while cutting, the drive

disc should be one of the first items

inspected for wear. The drive disc is

an expendable item and needs to be

replaced on a regular basis.

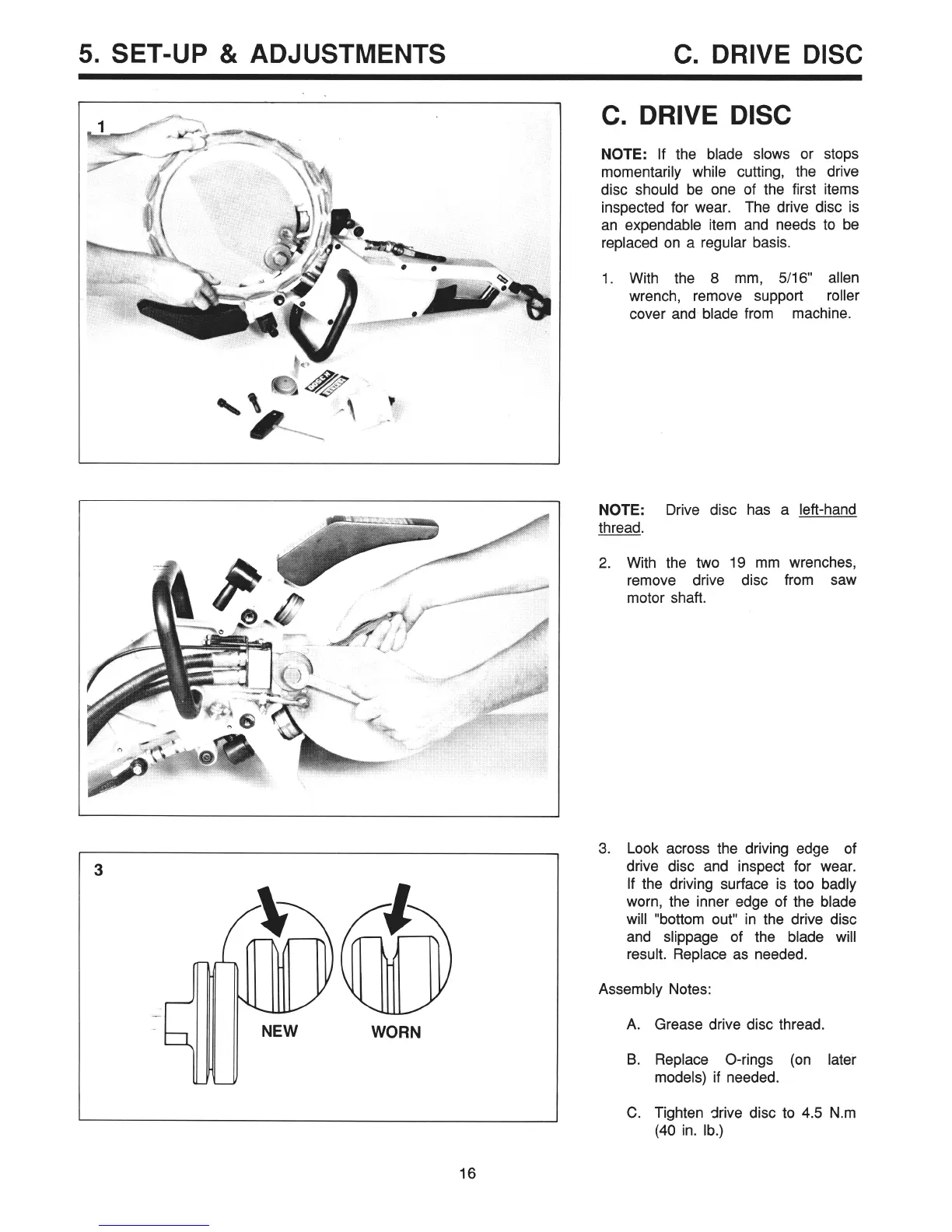

1. With the 8 mm, 5/16” allen

wrench, remove support

roller

cover and blade from machine.

NOTE:

Drive disc has a left-hand

thread

A

2. With the two 19 mm wrenches,

; . . ‘..

remove drive disc from saw

motor shaft.

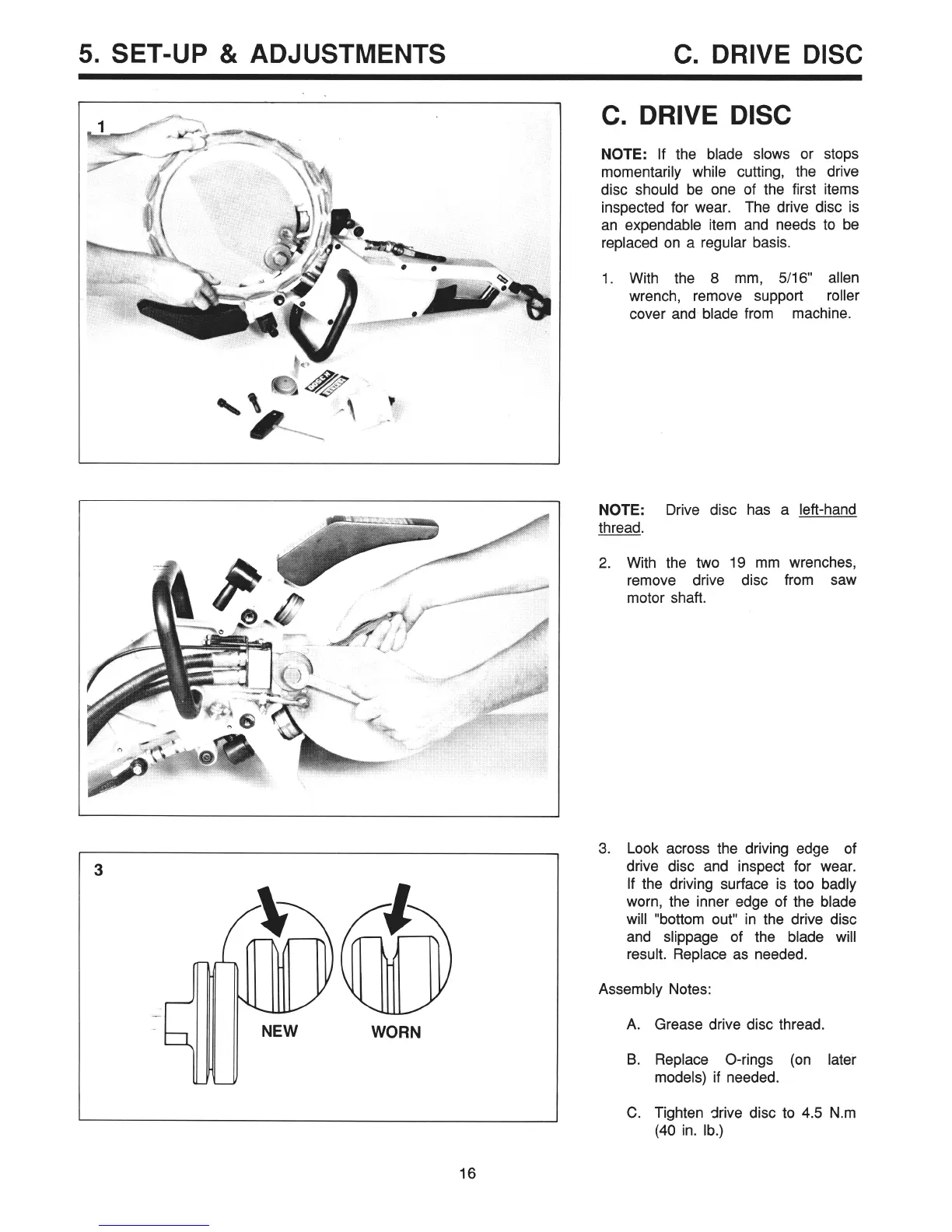

3. Look across the driving edge of

drive disc and inspect for wear.

If the driving surface is too badly

worn, the inner edge of the blade

will “bottom out” in the drive disc

and slippage of the blade will

result. Replace as needed.

Assembly Notes:

A. Grease drive disc thread.

B. Replace O-rings (on later

models) if needed.

C. Tighten drive disc to 4.5 N.m

(40 in. lb.)

16

Loading...

Loading...