Microdrive Series Instruction Manual

4201-109 Rev I

14

MICRODRIVE-i (UDi) SPECIFICATIONS

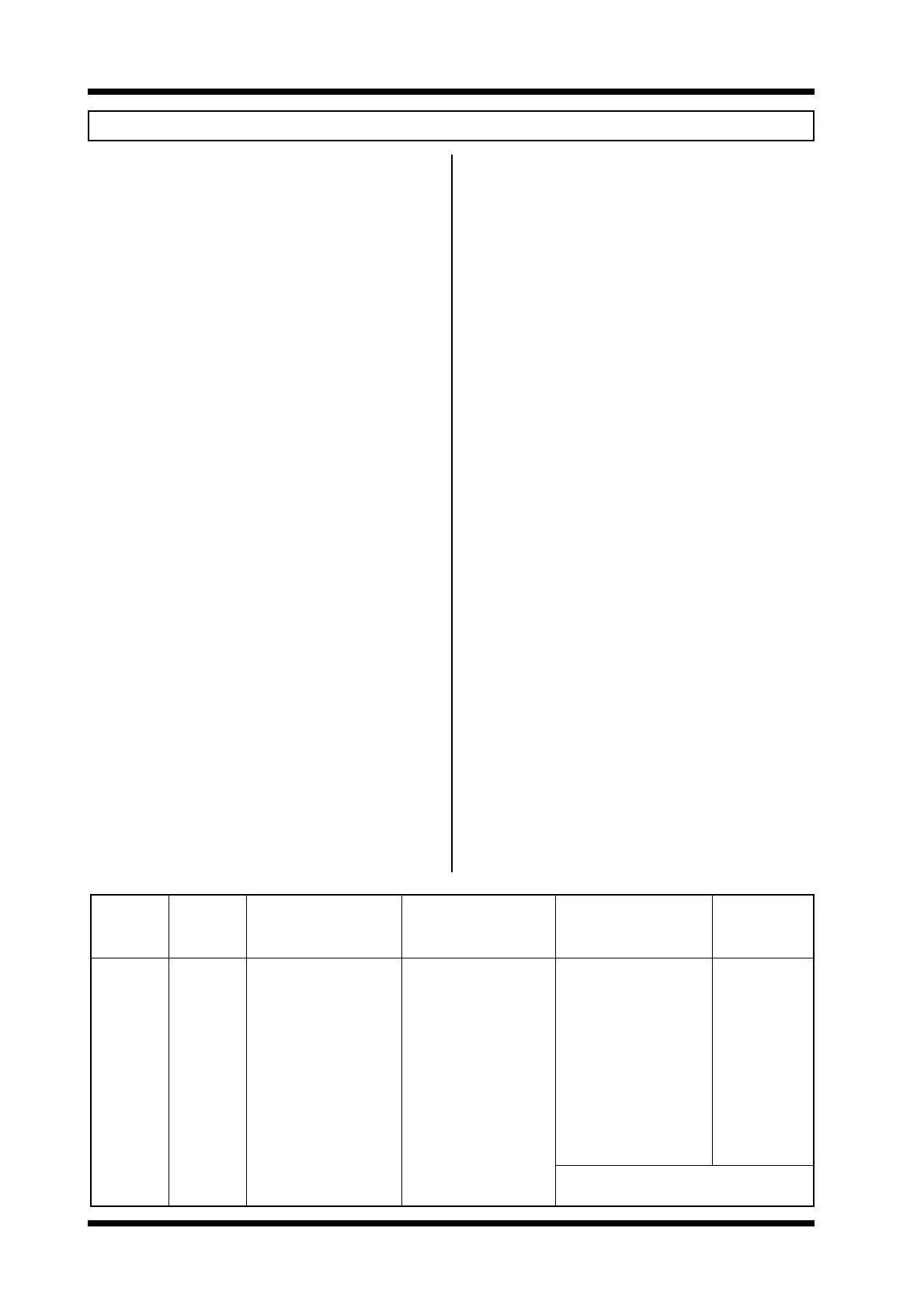

OUTPUT OUTPUT kVA OUTPUT POWER DIMENSIONS NETT

MODEL CURRENT 380Vac 415Vac440Vac 380Vac415Vac440Vac H W D WEIGHT

Amps kVA kVA kVA kW kW kW mm mm mm kg

UDi90 90 59.2 64.7 68.6 45 51 55 1350 405 422 126

UDi110 110 72.4 79.1 83.8 55 59 63 1350 405 422 126

UDi140 140 92.1 101 107 75 80 80 1350 405 422 126

UDi170 170 112 122 130 90 90 100 1350 545 422 160

UDi205 205 135 147 156 110 110 110 1350 545 422 175

UDi250 250 165 180 190 132 140 150 1350 545 422 175

UDi300 300 198 216 229 160 170 185 1350 965 422 303

UDi340 340 224 244 259 180 200 200 1350 965 422 303

UDi480 480 316 345 366 257 280 300 1350 965 422 333

UDi660 660 434 474 503 355 400 425 1350 1385 422 456

UDi830P 830 547 598 634 445 485 520 Consists of two UDi480

UDi1140P 1140 752 821 871 614 693 736 Consists of two UDi660

INPUT

Input supply voltage 380440Vac

Input supply tolerance -20% to +10%

Phase 3 phase, 3 wire,

earthed neutral supply

Input frequency range 4862 Hz

Power factor (fundamental) .95

Input current < output current

Power loss ride through > 2 seconds

May also be operated from 450700Vdc or 380440Vac

single phase supply - refer to Appendix 5.

OUTPUT

Current overload capability 150% for 30 seconds

Efficiency (full load, 50Hz) >97%

Power on delay <1 sec

Suit motor rated voltages 10995Vac

Suit motor rated frequencies 10250 Hz

Output voltage - cannot be greater than input voltage

Voltage regulation <±3%

Frequency range 0 to ±200Hz

Frequency resolution 0.01Hz

Control method Space vector modulation

Carrier frequency 2kHz (4kHz selectable)

Dominant ripple frequency 4kHz (8kHz selectable)

Tacho speed regulation 0.01%

ENVIRONMENTAL

Protection standard:

Cabinet Dust and water splash

protected; Pollution degree 3

Baseplate IP00; Pollution degree 2

Operating temperature 050°C

Storage temperature -40°C to +80°C

Relative humidity <90%, noncondensing

Altitude 1000m

Altitude derating (>1000m) -1% per 100m; 3000m max

UDi PROTECTION

Supply loss Input phase loss

Output current limit IGBT overload

Short circuited load Ground fault

Low DC bus voltage Regeneration limit

Excessive DC bus voltage Motor over temperature

UDi thermal model Control PCB failure

Dynamic brake thermal model Serial comms loss detection

MOTOR PROTECTION

Stall avoidance Stall protection

PTC thermistor input Phase current imbalance

Shear pin mode Combined overload alarm

Thermal model overtemperature trip

FREQUENCY CONTROL SOURCES

010Vdc 420mA

Greater of 010Vdc or 420mA

Keyboard Inch 1, Inch 2

Process follow Process control

Switch control - continuous Switch control - 7 preset

Motorised potentiometer RS232/RS485 (Options)

CONFIGURABLE SWITCH CONTROLS

Stop Start

Start/reset Stop/reset

Inch Inch latched

Direction invert Emergency stop

Latched start with direction Crane functions

RS232/RS485 control input (Options)

CONFIGURABLE RELAY OUTPUTS

3 relays; 230Vac/30Vdc/1A

1 x change over; 2 x normally open

Output selection:

Failsafe fault UDi started

UDi running UDi started or running

UDi overloaded Motor overloaded

Frequency sense point Current sense point

Direction At set frequency

Combined overload alarm Feedback sense

Power flow direction RS232/485 controlled

(Options)

CONFIGURABLE 010V ANALOGUE OUTPUT

Output selection:

0100Hz 0150% UDi current

0200Hz 0500Vac output voltage

010V RS232/RS485 (Options)

0150% UDi torque component of current

0150% motor power

DIGITAL FREQUENCY OUTPUT

26.25 times the UDi output frequency

CURRENT LIMIT SOURCES

010Vdc 420mA

Keyboard

Loading...

Loading...