Microdrive Series Instruction Manual

4201-109 Rev I

57

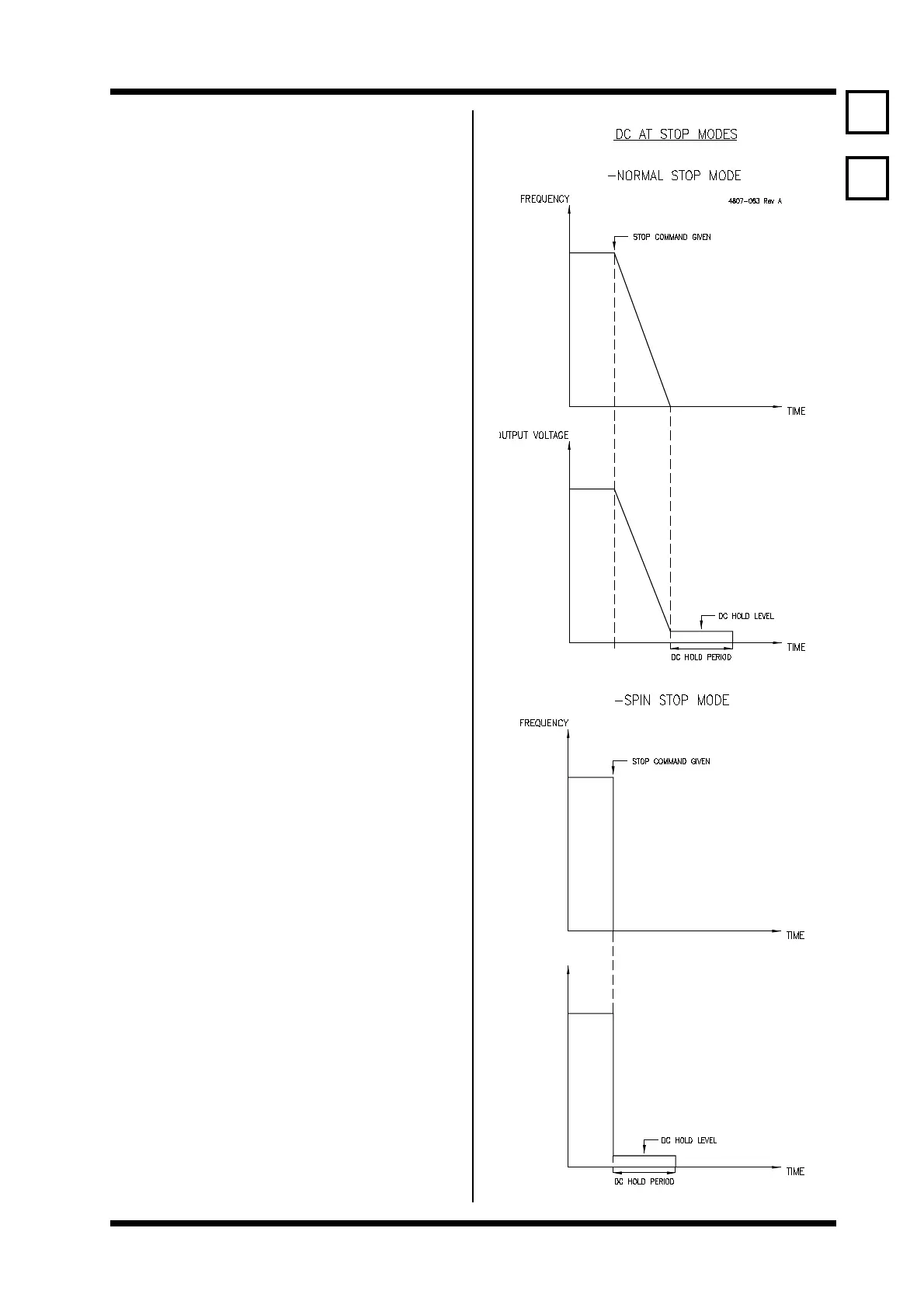

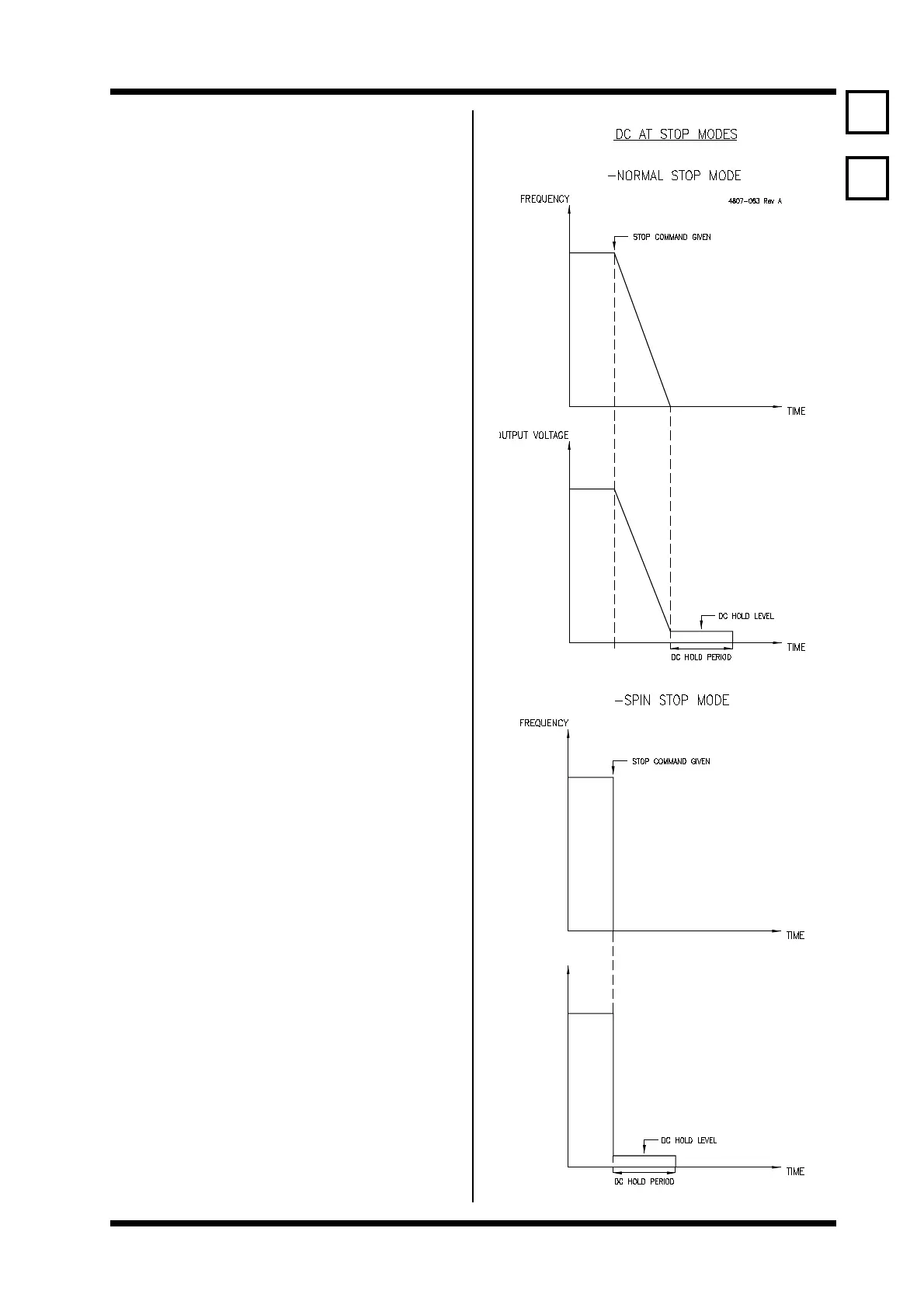

26, 27 DC STOPPING CONTROLS

Screen 26 DC LEVEL =0%

Description DC (0Hz) HOLD/BRAKE VOLTAGE AT STOP

Min/Max 0/25

Units %V(MOTOR)

Screen 27 DC TIME =0.0s

Description PERIOD OF DC HOLD VOLTAGE AT STOP

Min/Max 0.0/25.0

Units SECS

FUNCTION DC level sets the amount of DC voltage (hence

current) applied to the motor when the

Microdrive frequency reaches zero when

stopping. When applied, the DC current causes

the motor to resist movement and is used to

brake the motor.

DC Time sets the period of application of the DC

level after the Microdrive has reached zero

frequency, upon receiving a stop command.

Using DC at stop together with the spin stop

mode (Screen 61) can be useful in positioning

control systems.

Notes: To achieve DC holding while the control

frequency is at zero, but the Microdrive is not

stopped, use the boost voltage (Screen 14).

SETTING UP If motor braking upon stopping is not required,

leave both settings to zero (factory set values).

If braking at stop is required, set the DC time to

a suitable value (e.g., 2 seconds). While

repeatedly stopping the motor, adjust the DC

level to provide the desired braking force

(typically achieved when the motor current

equals its rated current). You must be careful

that you do not overheat the motor by operating

for too long at zero frequency, with too much

DC level, or without adequate cooling. Be

careful not to set the DC level so high that it

causes the Microdrive to current limit (status

display - ILT).

26

27

Loading...

Loading...