Microdrive Series Instruction Manual

4201-109 Rev I

52

17 FEEDBACK (S-CURVE) TIME CONSTANT

Screen 17 T CONST= 0.05s

Description FEEDBACK/S-CURVE TIME CONSTANT

Min/Max 0.00/0.50

Units SECS

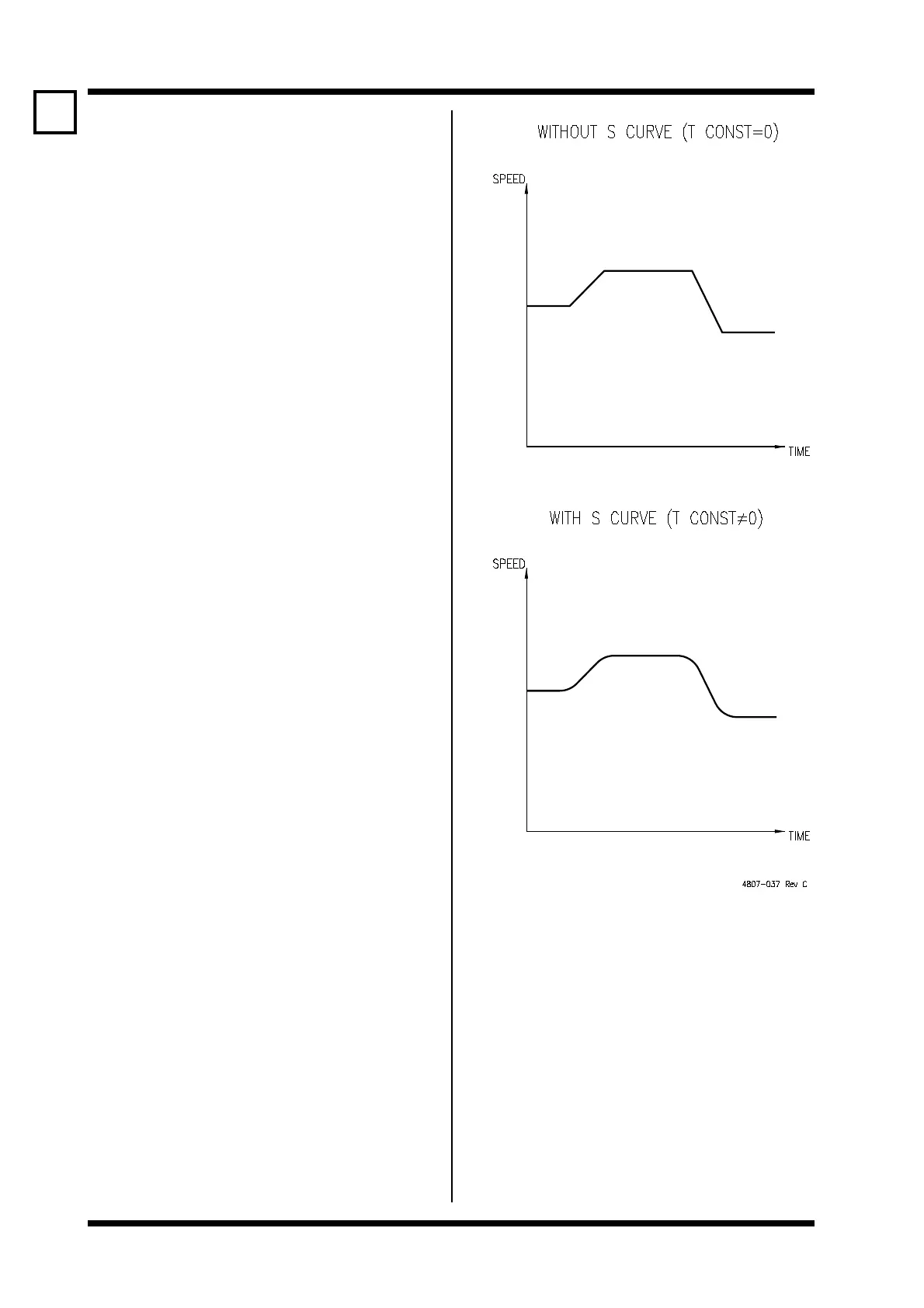

FUNCTION S-Curve:

When the feedback source (Screen 65) is

set to open loop to provide S-curve

acceleration, internal feedback is connected.

The feedback time constant then effectively

becomes the S-curve time constant. S-curve

is used to provide a soft change in torque

during acceleration or deceleration. Use S-

curve to reduce harshness of acceleration.

Typical uses include reducing the effects of

slackness in chains or couplings and the

soft acceleration of high inertia loads

(flywheels, large fans and pumps). S-curve

is also useful for improving the Microdrive's

ability to operate with voltage limiting.

Closed Loop Process Control:

The Microdrive may be connected and

configured for closed loop process control

(Screen 65). If Screen 65 is set to a

feedback source other than open loop, the

feedback time constant adjusts the rate of

response to the process.

SETTING UP Unless S-curve acceleration or feedback is

being employed, leave the time constant set

to 0.0 seconds.

Select the appropriate feedback source

using Screen 65.

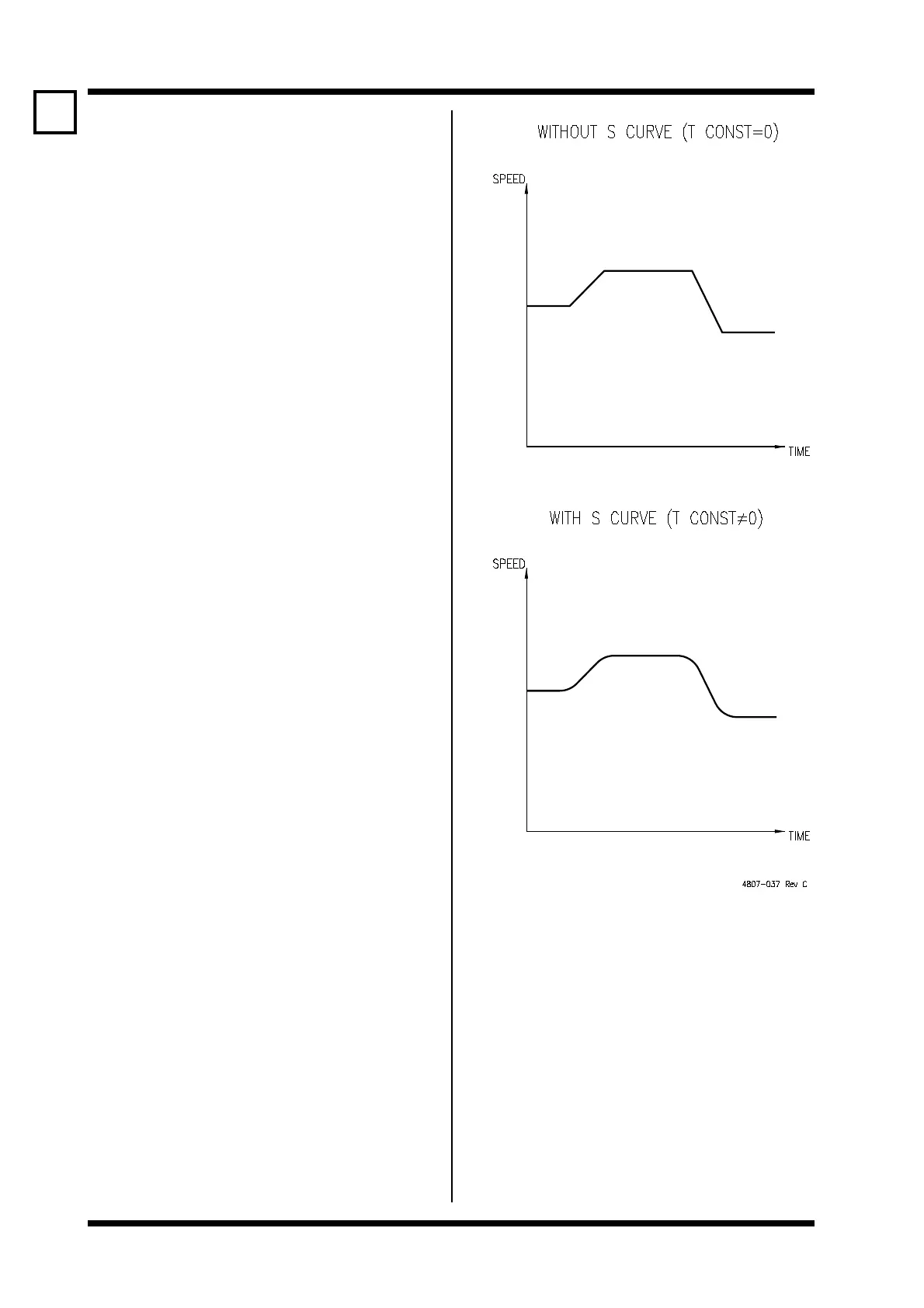

S-Curve:

Set the S-curve time constant to achieve the

degree of acceleration softening required.

Choose a setting consistent with the

acceleration/deceleration settings (the S-

curve time would typically equal 520% of

the acceleration/deceleration time).

S-curve may be used as an alternative to a

lower deceleration rate to help avoid voltage

limiting problems when decelerating loads

with high inertia.

Process control:

Reducing the feedback time constant will

give faster process control response, while

lengthening it will give improved process

control stability. Adjust the feedback time

constant to achieve an acceptable balance

between response time and stability.

Hints: Generally, the easiest way to set up the

feedback time constant is to initially use a

long feedback time constant (0.200.50

seconds) and once everything else is going,

finally reduce the time constant to achieve

faster response only if necessary.

Response that is too fast will lead to

instability of control.

17

Loading...

Loading...