TYING MACHINE FIXION 2

29_133084-G

6. MAINTENANCE

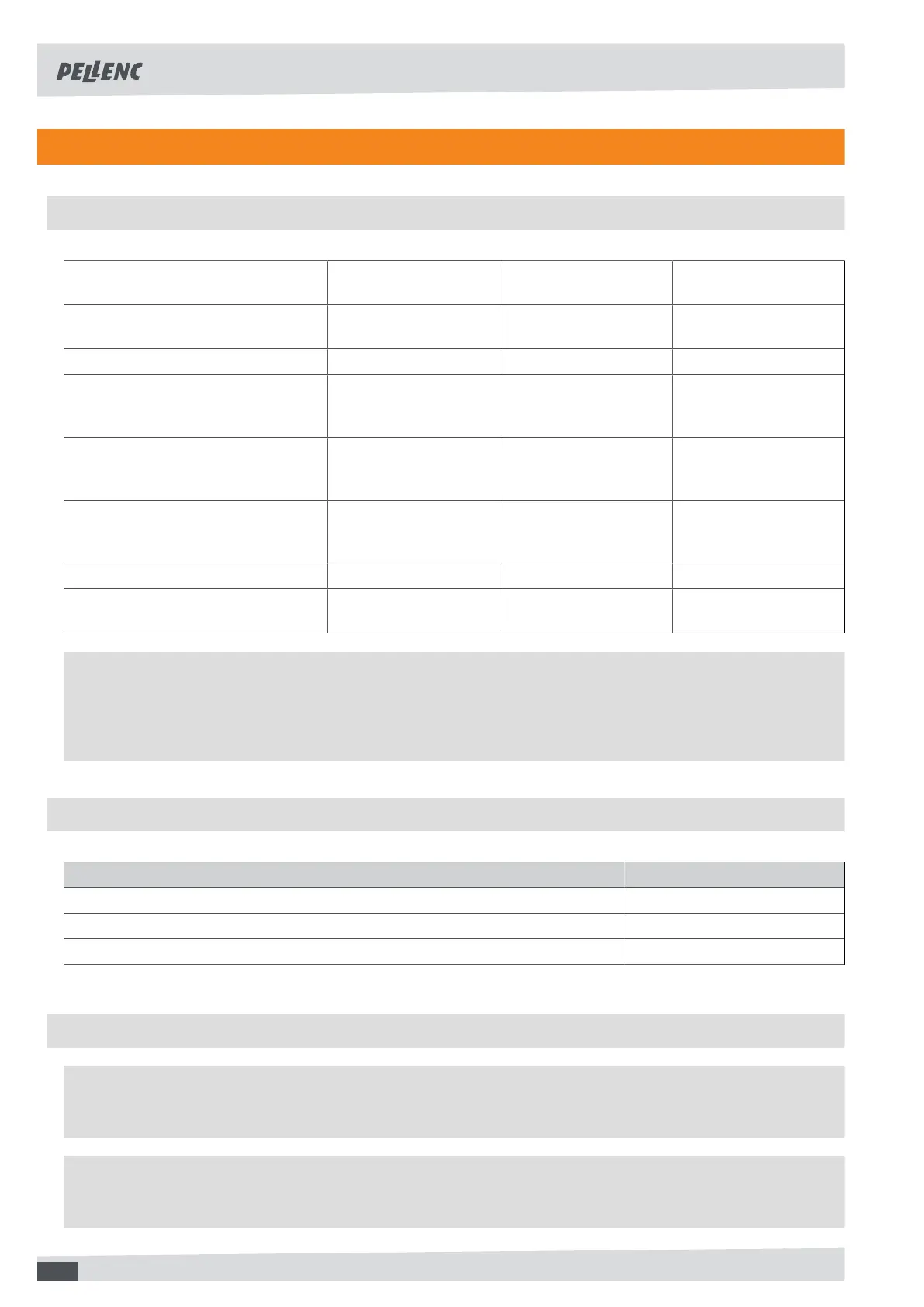

6.1. MAINTENANCE TABLE

Maintenance task At each start-up After each use

Every year or

every 300,000 ties

Cleaning the tool, see Section 6.3,

“Nettoyage”

X

Visual inspection of the tool X X

Check the support roller and replace

if necessary, see Section 6.5, “Re-

placing the support roller”.

X

Check the twister and replace if nec-

essary, see Section 6.6, “Replacing

the twister”.

X

Check the upper guide and replace

if necessary, see Section 6.4, “Re-

placement of the upper guide”

X

Check the ties with the tool X

Have the tool checked by an autho-

rised PELLENC dealer.

X

Important

Have the tool serviced every 300,000 attachments or at least once a year by an authorised dealer PELLENC

to ensure that necessary servicing is carried out sufficiently to ensure the longevity of your tool. Always store

the tool clean and in a dry place, with the battery charged.

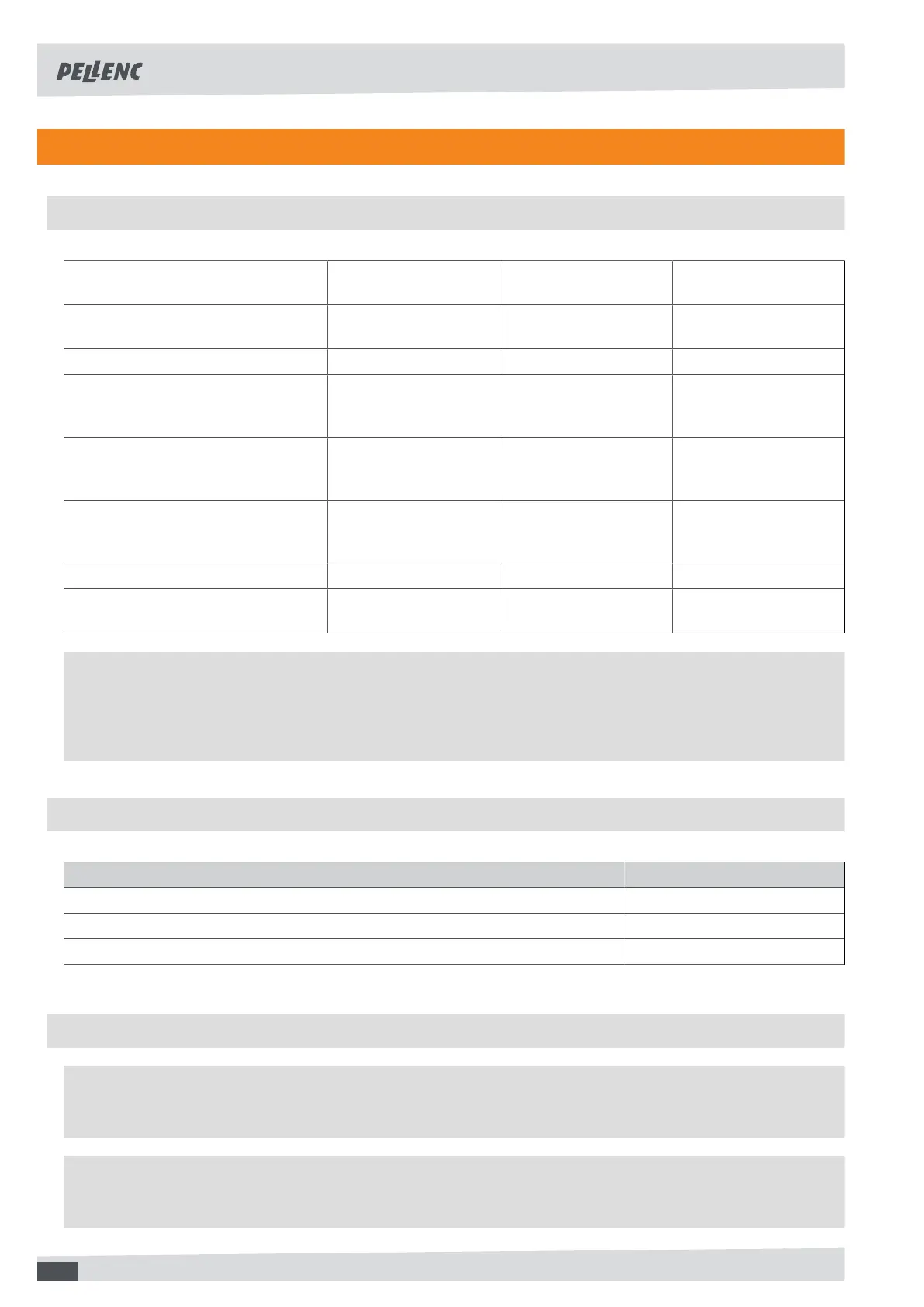

6.2. SPARE PARTS

Spare parts reference

Support roller 17828

Upper guide 155881

Twister 17849

6.3. NETTOYAGE

Important

Do not oil the central part where the ties pass through, as this could cause a malfunction.

Important

Do not use products such as trichloroethylene, white spirit, petrol etc.

28

Loading...

Loading...