7083-171H • February 23, 2015 www.pelprostoves.com8

D. Firepot Burn Down

A feature of these pellet stoves is the fi repot burn down

cycle. The frequency of the cycle is once every hour the

unit is burning. During this event, the feed is reduced to

the lowest setting and the exhaust blower ramps up to

the highest setting. The purpose of the burn down cycle

is to help remove debris from the fi repot and help the unit

burn as effi cient as possible. The cycle lasts 99 seconds.

Please be aware that the burn down does not replace daily

cleaning activities but makes them easier.

E. Shutdown

To shut the appliance down, turn the dial control counter

clockwise to the OFF position. During the shutdown pro-

cess, the LED will fl ash green rapidly just like the ignition

sequence. The fi repot burn down cycle will begin but with-

out the feed motor running. The feed will be terminated

during this shutdown process. The exhaust and convection

blowers will remain on during the shutdown process until

the exhaust has cooled.

If maintenance or daily cleaning is going to be conducted

immediately following a shutdown, please use caution as

components especially those inside the fi rebox may still be

hot.

Please note that if the dial control is turned to the off

position and back on even if by mistake, the unit will

go through the shutdown sequence.

F. Starting Your First Fire

1) Turn the dial control to “OFF”.

2) Make sure the fi repot is clean, inplace, and free of

debris.

3) Plug the unit into the wall and fi ll the hopper with

wood pellets. Shut the hopper lid.

4) Turn the dial control to the desired burn setting.

The unit will go into the ignition sequence followed by

start up (The green LED will fl ash rapidly). The igni-

tion sequence involves the exhaust blower turning on,

the igniter turning on, and the feed motor running in two

stages. The fi rst stage involves the feed motor running

continuously for about a minute to preload pellets into the

fi repot. Following the preload and a delay, the feed motor

will begin cycling on and off. When the pellets are warming

up and on the verge of igniting, it is not uncommon for the

fi rebox to fi ll with smoke. Once ignition actually happens,

the smoke should evacuate quickly. During this stage as

well as any part during the burn process, the front door

should not be opened. This cycle continues until the unit

senses ignition by a rise in the exhaust temperature or the

unit times out. Following the ignition cycle the unit begins

to feed additional pellets gradually for a few minutes to

build up the fi re. This is important to have a controlled start

up to keep the unit in balance.

G. Fire Characteristics

The overall height of the fl ame will vary throughout the

burn for a couple of reasons. First is that the fl ame will

vary based on type of fuel or even batch of fuel. Secondly,

the unit adjusts the burn rate according to the how far

away the room temperature is from the set temperature.

This should not cause alarm. The third characteristic that

affects the fi re relates to general maintenance and clean-

ing. Infrequent or poor general maintenance will result is

poorer performance. Indicators of the need for additional

maintenance activities include a lazy fl ame, black sooted

glass, pellets not igniting, or pellets falling to the side of the

fi repot. See the maintenance section for additional infor-

mation.

Odors, vapors, and smoke released during initial

operation.

• Curing of high temperature paint.

• Open windows for air circulation.

Odors may be irritating to sensitive individuals.

CAUTION

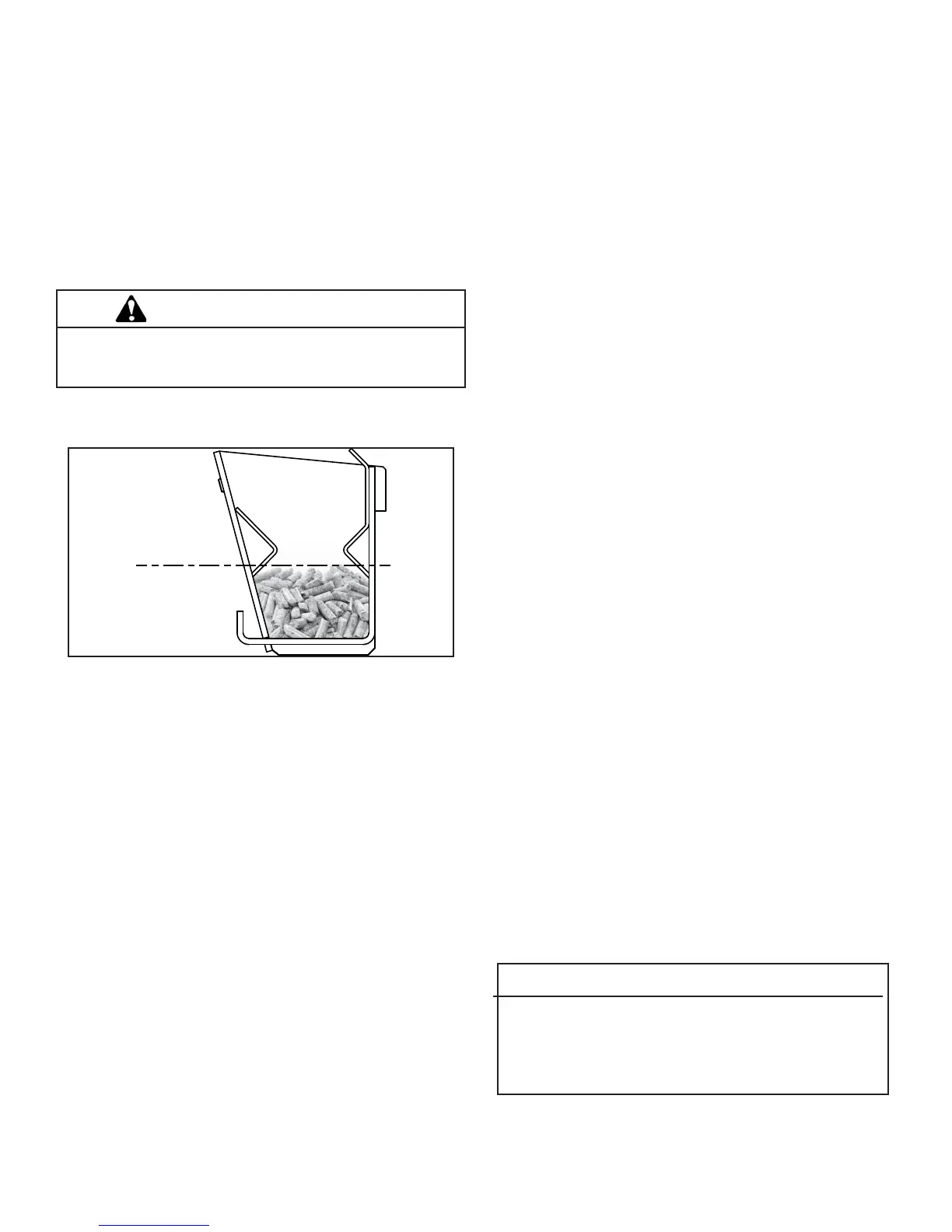

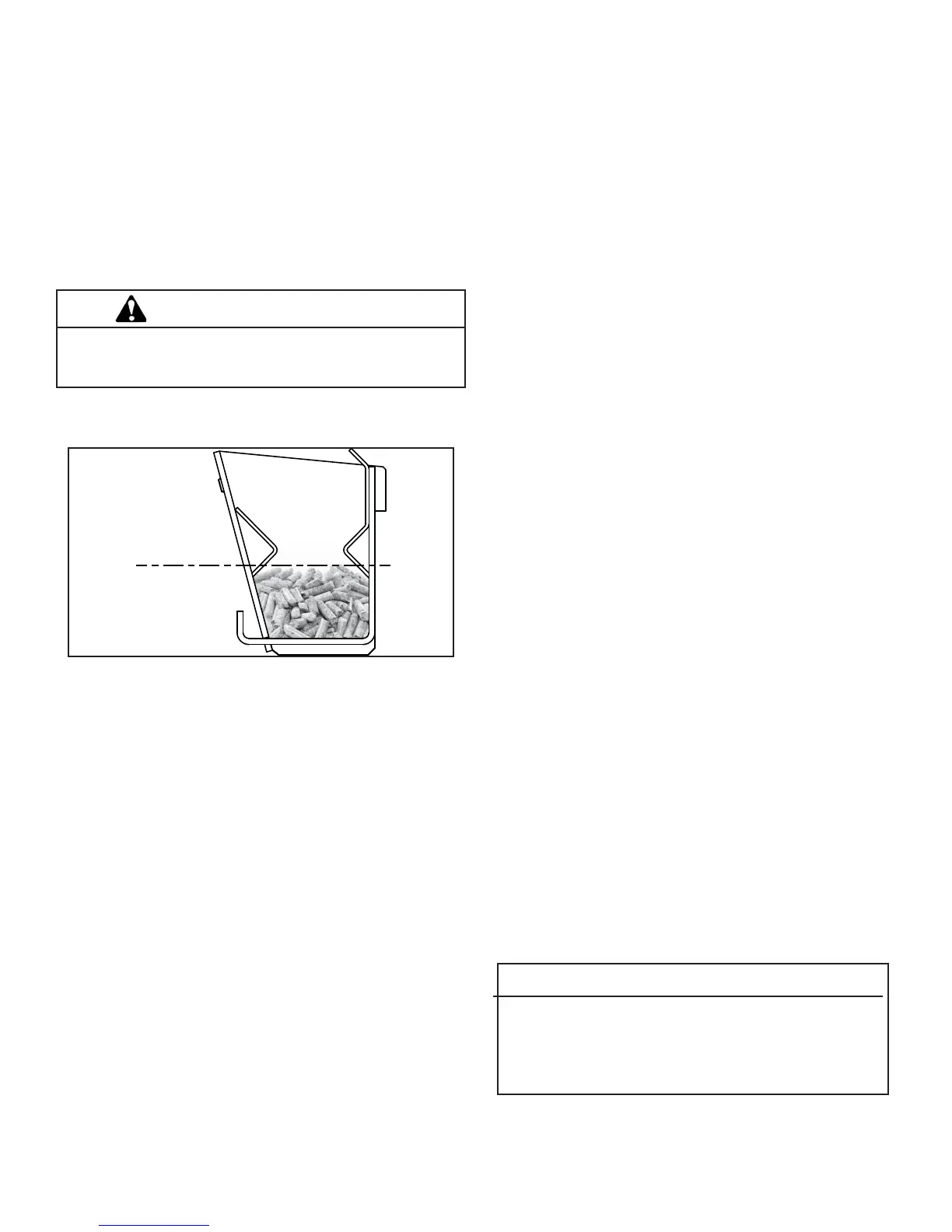

C. Priming the Feed Tube (Cont’d)

A FIREPOT THAT IS MORE THAN HALF FULL IS OVER-

FILLED AND CAN BE DANGEROUS. DO NOT OVERFILL

FIREPOT FOR IGNITION.

If the stove does not ignite follow directions below. The

LED light should blink red four times showing a missed

ignition.

Turn the stove to off and remove and EMPTY the fi repot.

CAUTION

Overfi lling the fi repot could cause an unsafe

ignition resulting in injury or damage. Firepot must

be emptied.

Return the fi repot to the stove correctly (step 3) and then

repeat step 6.

MAXIMUM

PELLET LEVEL

Loading...

Loading...