Operators Manual Model PT2000/H Series Gas Monitor Rev 2. January 2014

9.0 Sensor Calibration

Refer to Table at the end of this section for the recommended calibration gas for the

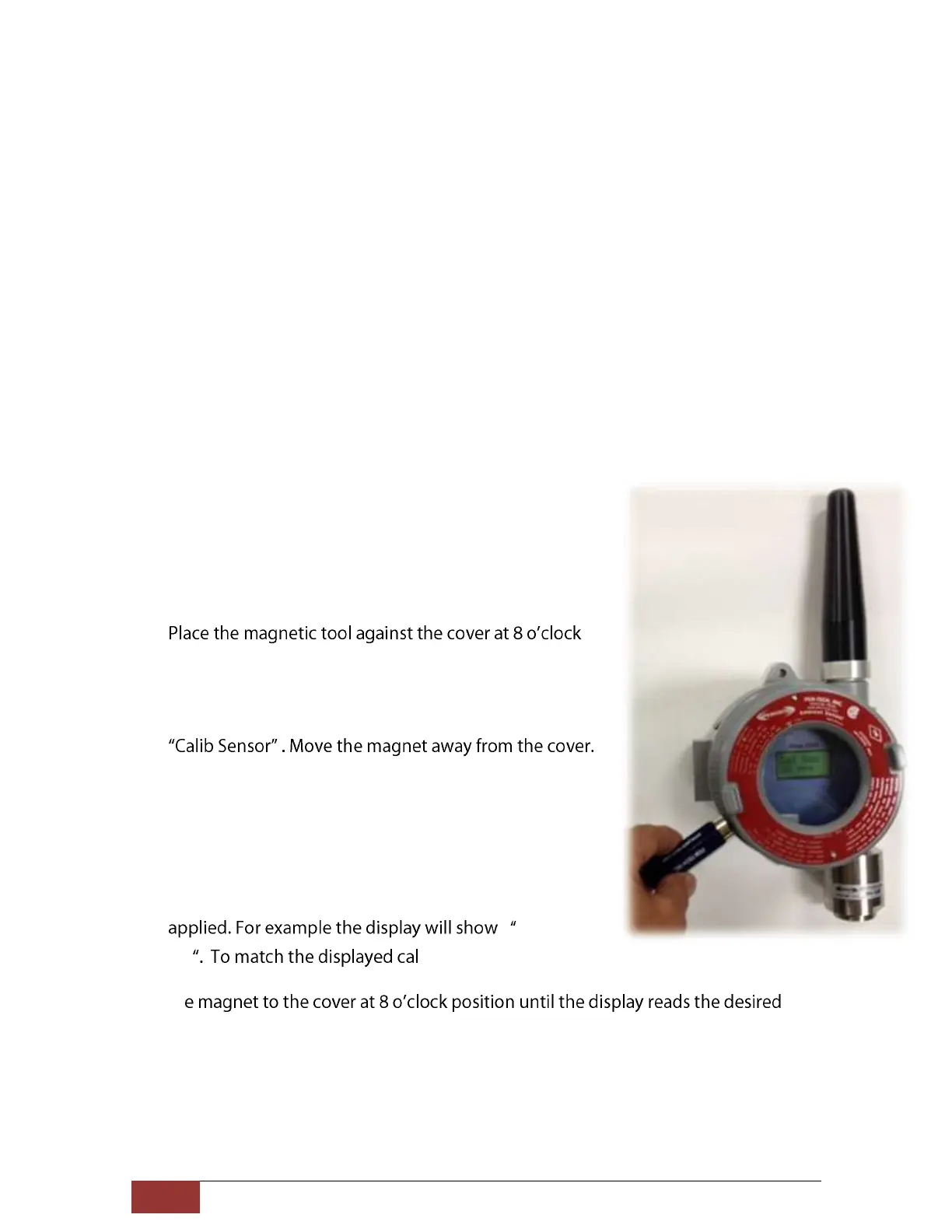

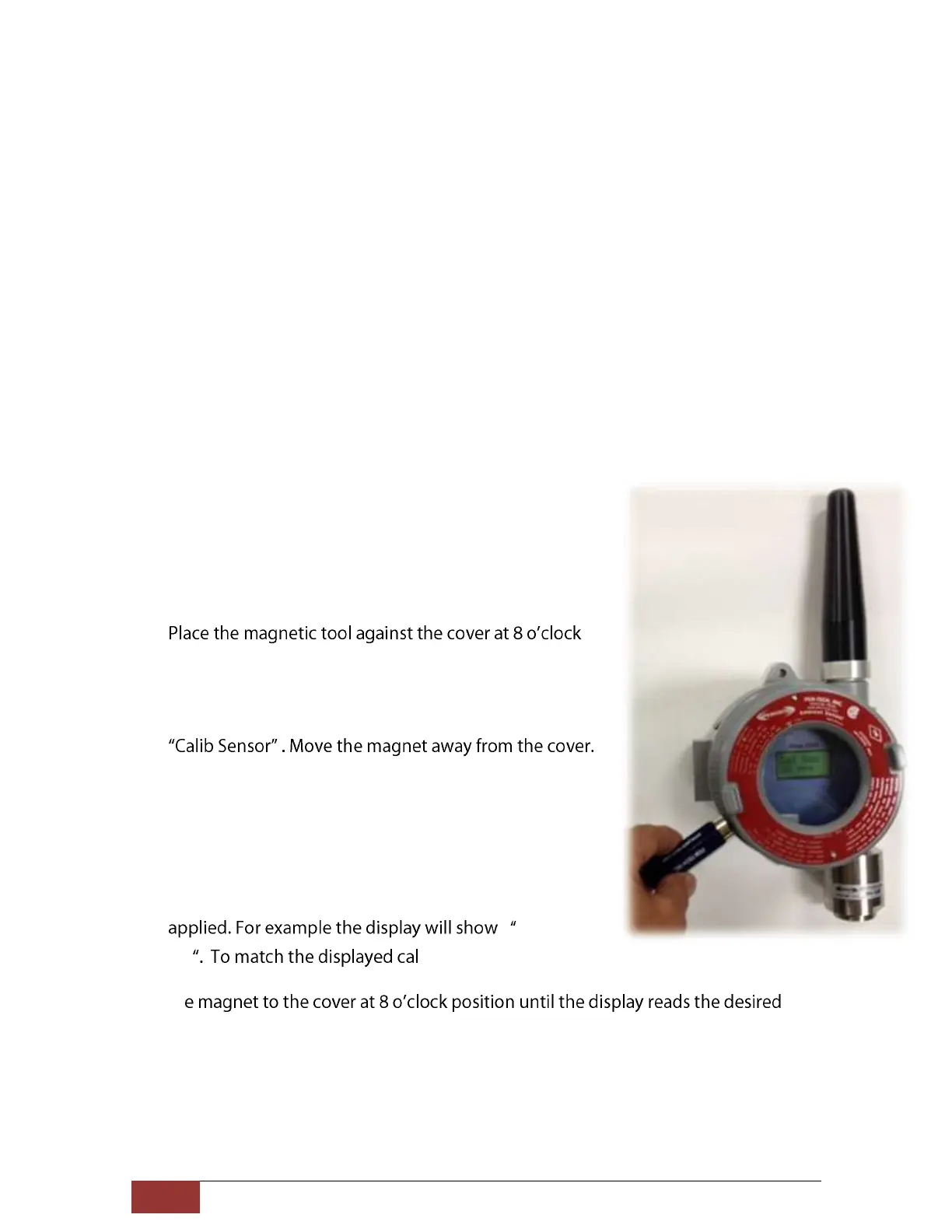

target sensor.

Following items are needed for the sensor calibration:

Calibration adapter with tubing

Magnet tool to activate the magnetic sensor on the transmitter board assembly.

Calibration gas bottle with flow regulator. The flow of the calibration gas should

be approximately 1.5 LPM (liters per minute)

See Figure 12

The sensor can be auto calibrated without removing the enclosure cover and

declassifying the zone. A magnet tool is used to activate the internal switch to initiate

the calibration.

Follow the steps below to calibrate the sensor.

1. Make sure the detector and ambient air is clear of gas

vapors.

2. Remove the rain / splash guard if attached.

3.

position to activate the magnetic switch as shown in

figure 11.

4. Place and hold the magnet until display indicates the

5. While the Calib Sensor message is being displayed the

sensor is making its initial adjustments. It may take 5 to

10 seconds. (Note: Do not apply calibration gas yet)

6. Once the initial adjustments are made the sensor will

display the concentration of the calibration gas to be

Cal Gas

50 -gas reading to the

calibration gas bottle being used simply place and hold

th

cal-gas value. Typically the calibration is performed at mid scale. For example, the

H2S sensor with the detection range of 100 ppm the typical calibration gas should

be 50 ppm. The selected calibration gas value will be stored in the non-volatile

memory and remains unchanged until modified.

Figure 11.Sensor Calibration Mode.

Loading...

Loading...