4

P15003 (12-15-22)

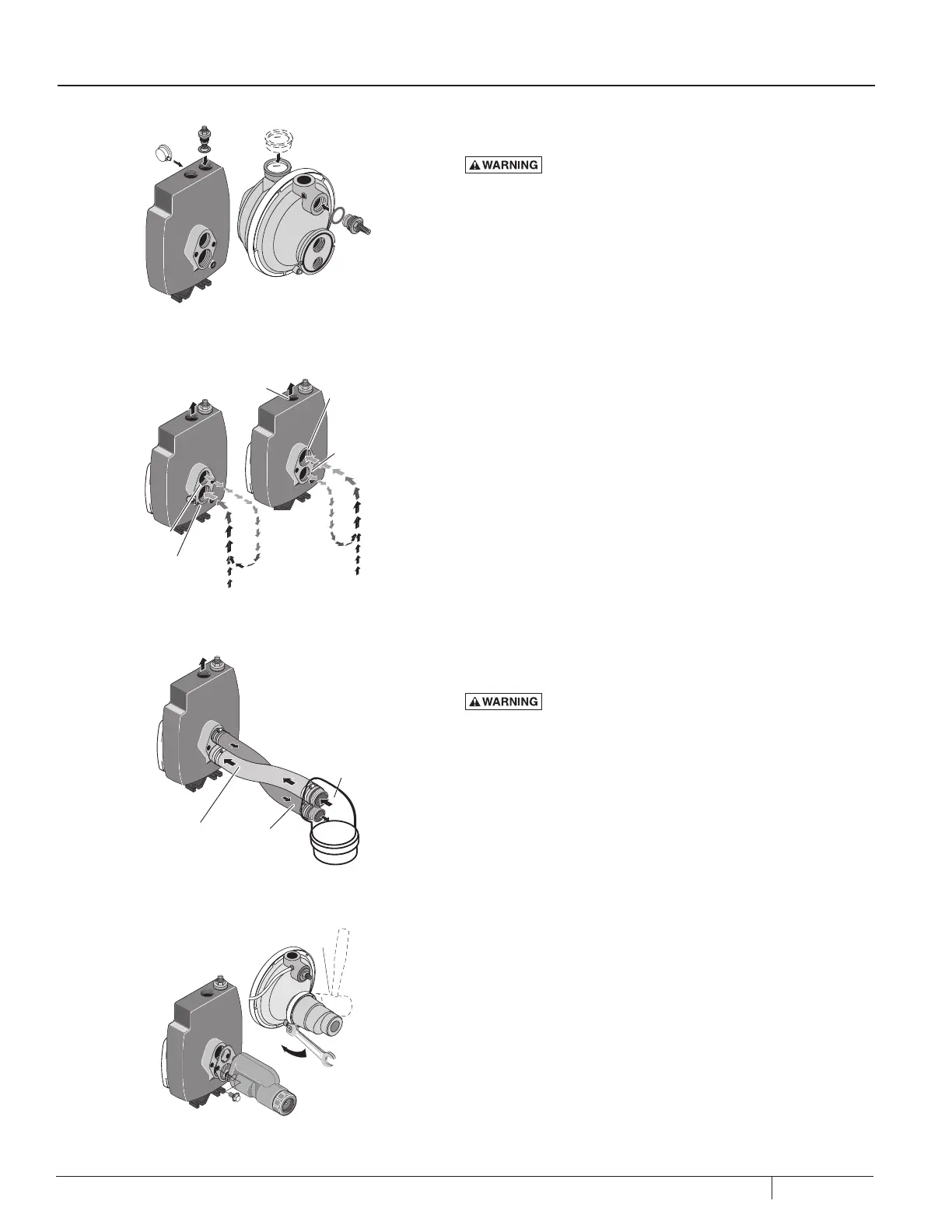

REPLACING AN EXISTING PUMP

DEEP WELL

RISK OF ELECTRIC SHOCK.

Can shock, burn or kill.

Disconnect power to pump before working on pump or motor.

1. Drain and remove the old pump. Check pipe for scale, lime,

rust, etc., and replace it if necessary.

2. Install the control valve and pressure gauge in the pump body.

3. If your old pump has the suction pipe (the larger port – see

Figure2) below the drive port, you will need to install flexible

pipe between the well head and the pump so that the

connection will be correct.

NOTE: Your old ejector (in the well) may not be properly

matched to your new pump. If the pump does not perform

properly, we recommend that you install Flotec ejector kit

FP4800.

4. Install the pump in the system. Make sure that all pipe joints

in the suction pipe are air-tight as well as water tight. If the

suction pipe can suck air, the pump will not be able to pull

water from the well.

5. Adjust the pump mounting height so that the plumbing

connections do not put a strain on the pump body. Support the

pipe so that the pump body does not take the weight of piping

or fittings.

You have just completed the well plumbing for your new deep

well jet pump. Please go to Page 8 for discharge pipe and tank

connections.

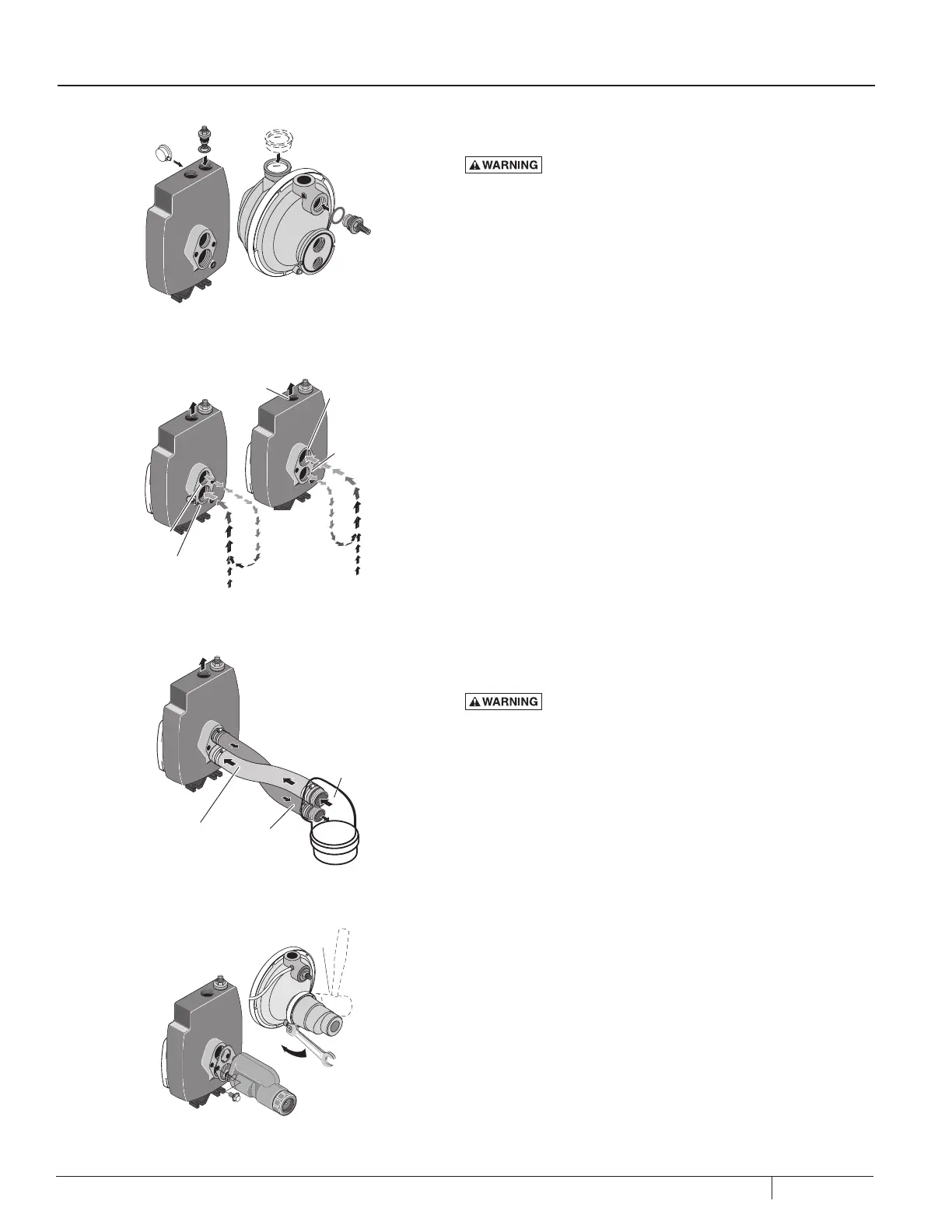

SHALLOW WELL

Risk of electric shock. Can shock, burn or kill.

Disconnect power to pump before working on pump or motor.

1. Drain and remove the old pump. Check the old pipe for scale,

lime, rust, etc., and replace it if necessary.

2. Install the control valve and pressure gauge in the pump body.

3. Install ejector kit FP4855 with a Series 4200, or kit FP4875

with a Series 4300 pump (kits are sold separately). Follow the

instructions provided with the kit. Be sure to align the venturi

with the top hole on the front of the pump.

NOTE: Always replace the ejector when replacing the pump in

a shallow well installation.

4. Install the pump in the system. Make sure that all pipe joints

in the suction pipe are air-tight as well as water tight. If the

suction pipe can suck air, the pump will not be able to pull

water from the well.

5. Adjust the pump mounting height so that the plumbing

connections do not put a strain on the pump body. Support the

pipe so that the pump body does not take the weight of piping

or fittings.

You have just completed the well plumbing for your new shallow

well jet pump. Please go to Page 8 for discharge pipe and tank

connections.

Figure 1 - Install Control Valve and Gauge

Drive

(Smaller

Port

Suction

Port

Suction

(Larger)

Port

2755 0197

Piping omitted

for clarity

Discharge

Drive

Port

Drive Pipe

sends water

down the well

to

drive water

up through the

Suction Pipe

to Pump Suction

Figure 2 - Drive and Suction Functions

Suction

Pipe

Drive

Pipe

Well

Head

If well head and pump

don't match, twist

reinforced flexible pipe

to connect drive

and suction pipes.

Figure 3 - Reversed Connections to Well

Tap clamp

to seat it

Figure 4 - Mount Ejector – Shallow Well

Loading...

Loading...