5

English

• Flow Sensor: A ow sensor assures that there will always be adequate water ow through the SC-75. If the SC-75 is not

properly plumbed and/or does not receive adequate water ow, no chlorine will be produced.

• Temperature Sensor: To protect the SC-75 from operaon and potenal damage when the temperature of the pool water

falls below 11° C, ±1.67° C, the temperature sensor switches the cell o, illuminates the COLD WATER light and no chlorine

will be produced.

• Salt Sensor: Two (2) salt sensor probes in the SC-75 are acvated each me the SC-75 is switched on and again during

every 12 hours of connuous running. At each of those mes, the salt level LED indicator lights ash in a scrolling sequence

for two (2) minutes to indicate that the SC-75 is in analysis mode. Aer two (2) minutes, the LED indicators lights will signal

one (1) of three (4) salinity ranges. For more informaon, see “Salt Level Status LEDs”.

Note: The salt sensor reading is within +/- 500 ppm accuracy.

SC-75 Power Center

The power supply is connected with the pool circulaon pump electrical source so that the SC-75 only operates when the

pool pump is on. The Power Center should be mounted vercally on the wall up to three (3) meter away from the cell. The

Power Center contains the transformer, fuse, and connector to the cell. A fuse holder is mounted on the boom of the Power

Center for addional protecon. There are no other controls or lights on the Power Center. For informaon about installing

and proper use of the Power Center, see the “SC-75 Power Center Installaon Guide” .

The SC-75 Power

Center does NOT

control the pump. The SC-75 Salt

Chlorinator only produces chlorine

when the pool pump is on.

Before plugging or

unplugging the SC-

75 Salt Chlorinator to the Power

Center, rst switch o the AC

power to the Power Center.

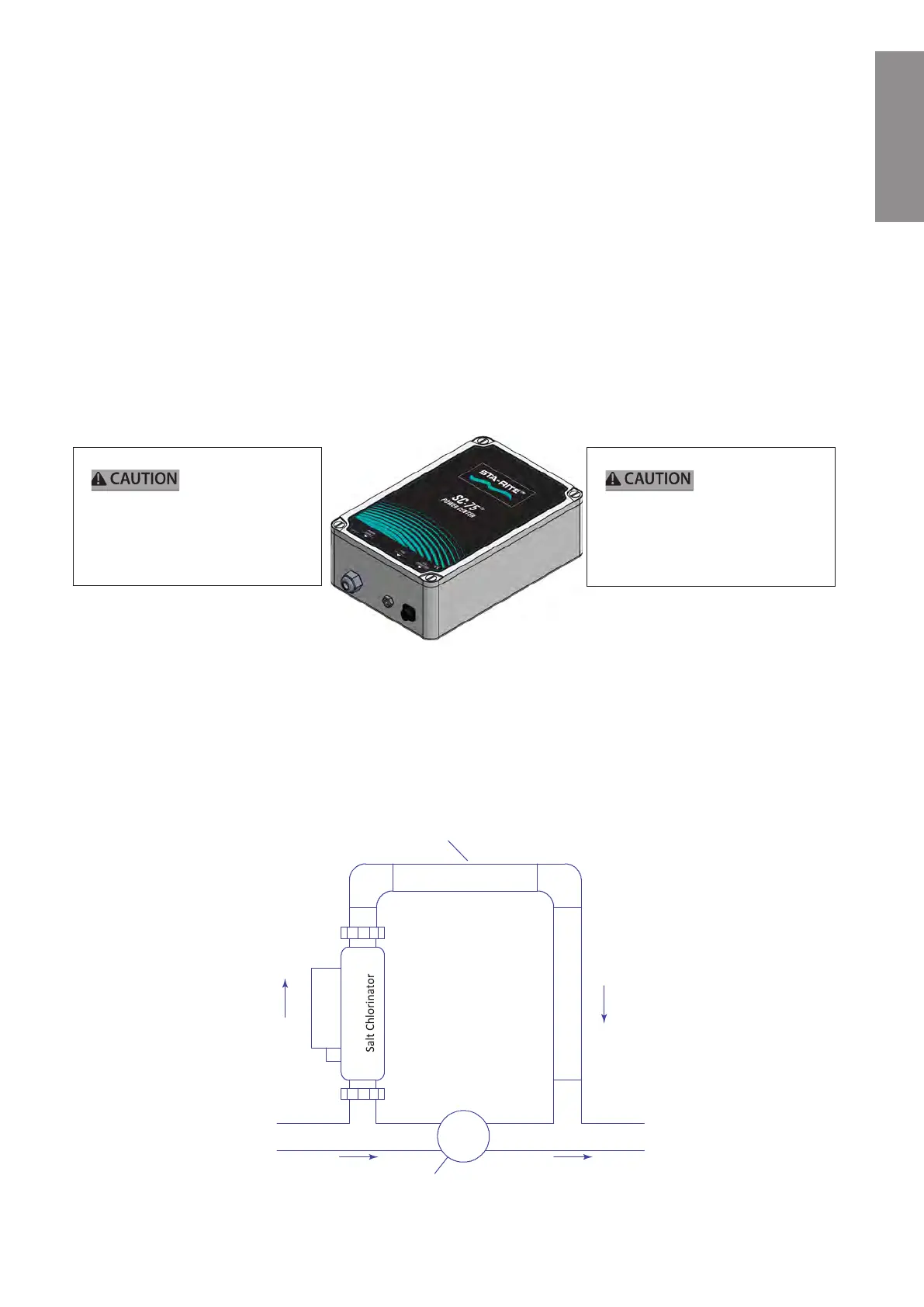

Loop Plumbing Diagram

The SC-75 Salt Chlorinator is designed to operate with water ow rates from 5.7 m³/h to not exceed 24 m³/h. For ow rates

over 18 m³/h minute you must use a bypass loop (as shown below) for best chlorine producon. Installaons with ow

rates over 18m³/h include those that have in-oor cleaning systems or booster pumps. These systems MUST use a bypass

loop with the SC-75 with a ow control valve that assures that the ow through the SC-75 is maintained within its designed

operang water ow rates.

Bypass Loop

FLOW

OUT

FLOW

IN

VALVE

FLOW IN

FLOW OUT

Flow Control Valve

“UPWARD FLOW”

NOT TO SCALE

SC-75

Loading...

Loading...